RT-SVX071D-EN

41

Requirements of Gas Heat

The unit gas train and optional through-the-base gas shut-

off valve are rated at 0.50 PSIG maximum. A pressure

reducing regulator is recommended to prevent this

maximum from being exceeded. These components must

be isolated during field gas piping test that exceed 0.50

PSIG.

Important: It is recommended that the field piping be

capped prior to the unit gas train or optional

through-the-base gas shut-off valve if present.

☐ Gas supply line properly sized and connected to the

unit gas train.

☐ All gas piping joints properly sealed.

☐ Gas piping leak checked with a soap solution. If piping

connections to the unit are complete, do not pressurize

piping in excess of 0.50 PSIG or 14-inch w.c. to prevent

component failure.

☐ Drip leg installed in the gas piping near the unit.

☐ Flue exhaust clear of any obstruction.

☐ Supply and manifold pressures should be checked

during unit commissioning (see Table 7, p. 41 and

Table 8, p. 41).

Table 7. Gas heat data - supply and manifold

pressure requirements – two-stage gas

YSJ(072-150)* YSJ(180-300)*

Heating Input Rate –

Btu/h

80,000 – 250,000 250,000 320,000 400,000

Minimum Supply Gas

Pressure NG/LP (in. w.c.)

4.5/11.5 4.5/11.5 6/11.5

Maximum Supply Gas

Pressure (in. w.c.)

14

Manifold Gas Pressure –

1st Stage - NG (in. w.c.)

1.8 1.7 1.8 1.7

Manifold Gas Pressure –

2nd Stage - NG (in. w.c.)

3.5 3.3 3.5 3.3

Table 8. Gas heat data - supply and manifold

pressure requirements - modulating gas

Digit 10 = B models

Heating Input Rate – Btu/h

80,000 – 400,000

Minimum Supply Gas Pressure NG/LP (in. w.c.)

5/11.5

Maximum Supply Gas Pressure (in. w.c.)

14

Manifold Gas Pressure – Full Gas Input Rate - NG/

LP (in. w.c.)

3.5/10

Modulating Gas Heat

For models YSJ(072,090,102,120,150)***B(H,L):

1. Confirm the vertical slide bracket on the DAS vertical

tube is positioned to block all the hole(s) for downflow

configuration.

Note: Number of holes will vary. Verify bracket is

covering all holes in the vertical tube, regardless

of quantity.

2. Removal of horizontal duct supply cover is required to

view DAS tubing located behind the heat exchanger

tubes.

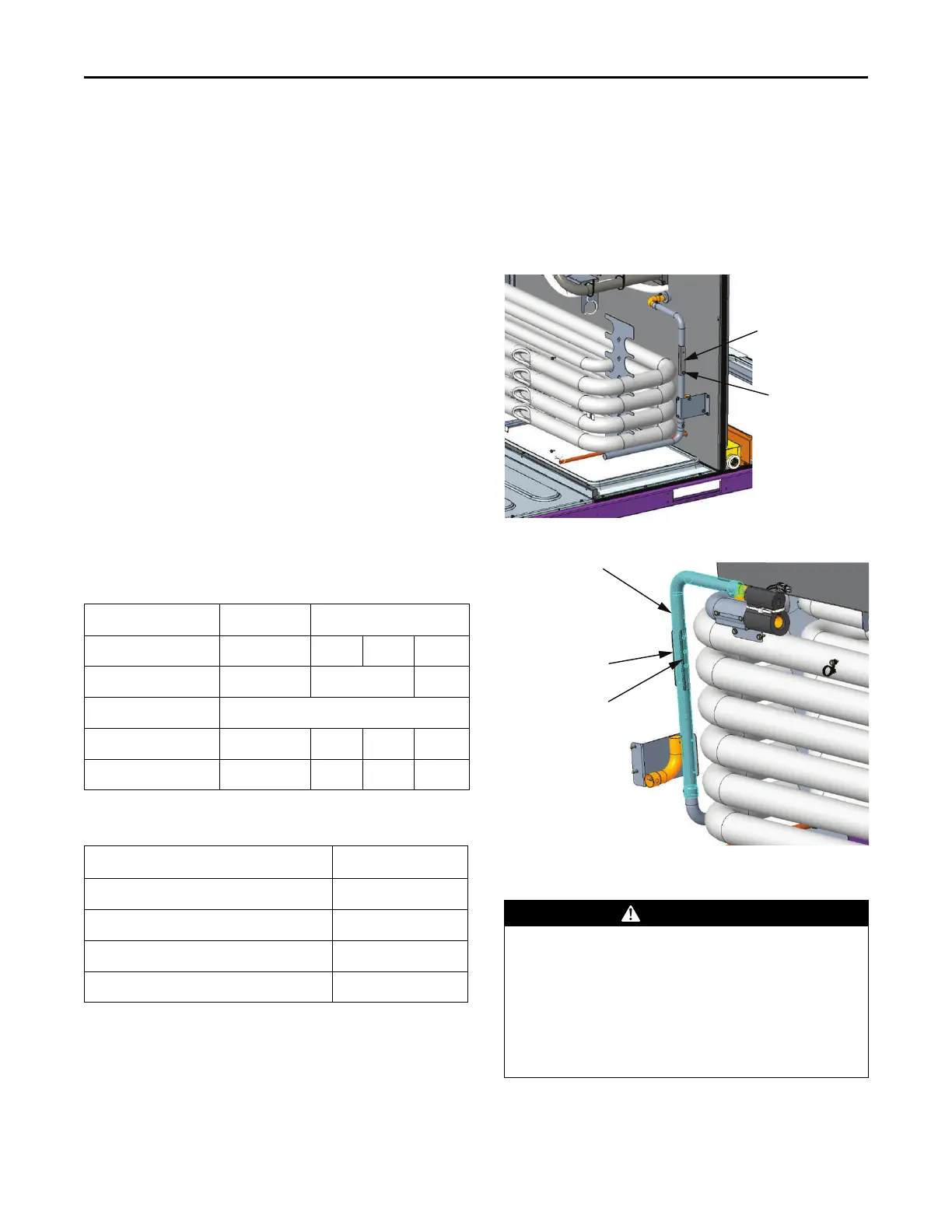

Figure 63. Downflow position shown

Bracket adjustment

screw

Vertical slide bracket

downflow position

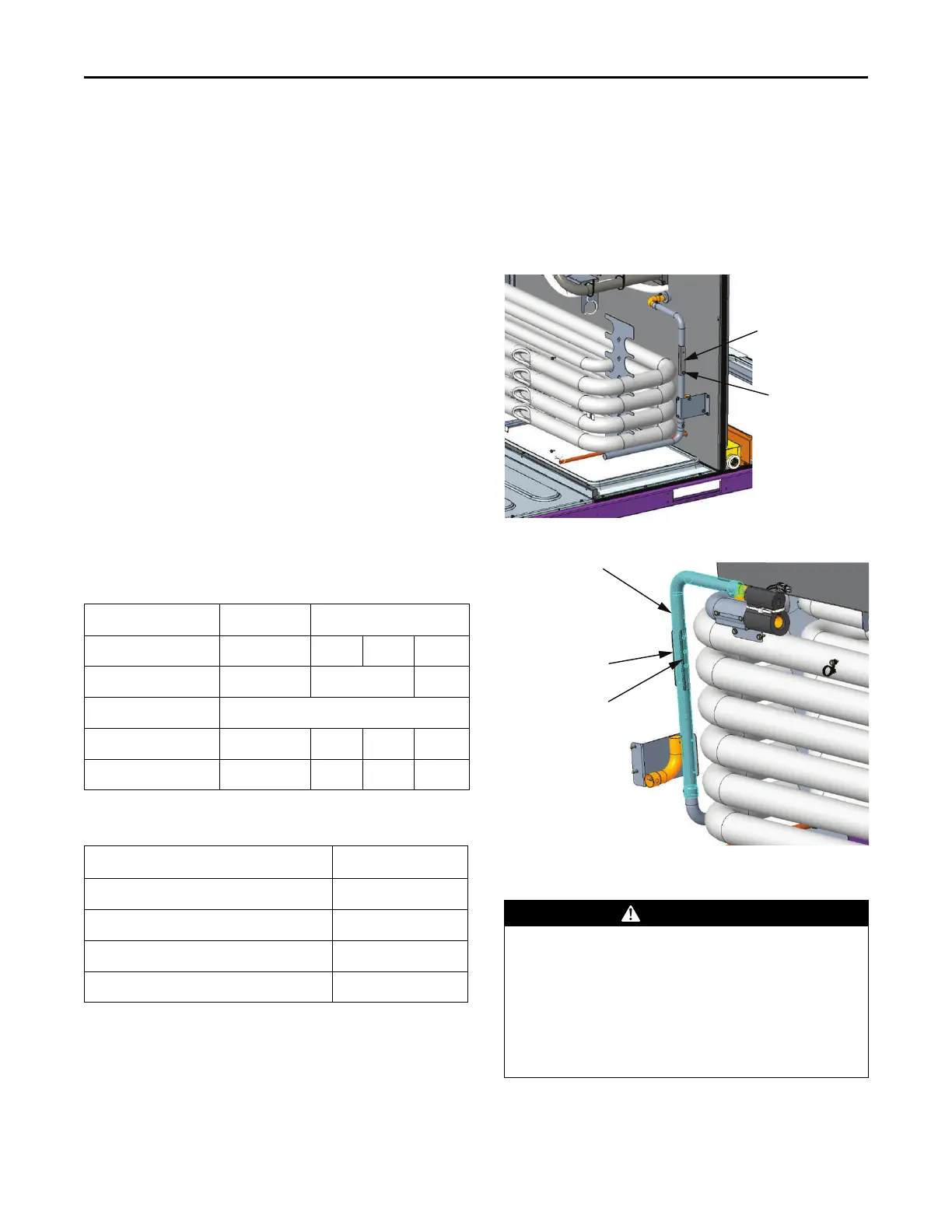

Figure 64. Vertical tube hole(s) location

Hole or holes

located here

Vertical slide bracket

positioned to block

hole(s)

Vertical DAS tube

Condensate Drain Configuration

WARNING

Hazardous Voltage!

Failure to disconnect power before servicing could

result in death or serious injury.

Disconnect all electric power, including remote

disconnects before servicing. Follow proper lockout/

tagout procedures to ensure the power can not be

inadvertently energized. Verify that no power is

present with a voltmeter.

An evaporator condensate drain connection is provided on

each unit. Refer to the ductwork section in the Installation

chapter for the appropriate drain location.

Installation

Loading...

Loading...