56 RTAC-SVX002A-EN

This section contains an overview

of the operation and maintenance

of RTAC units equipped with CH530

control systems. It describes the overall

operating principles of the RTAC design.

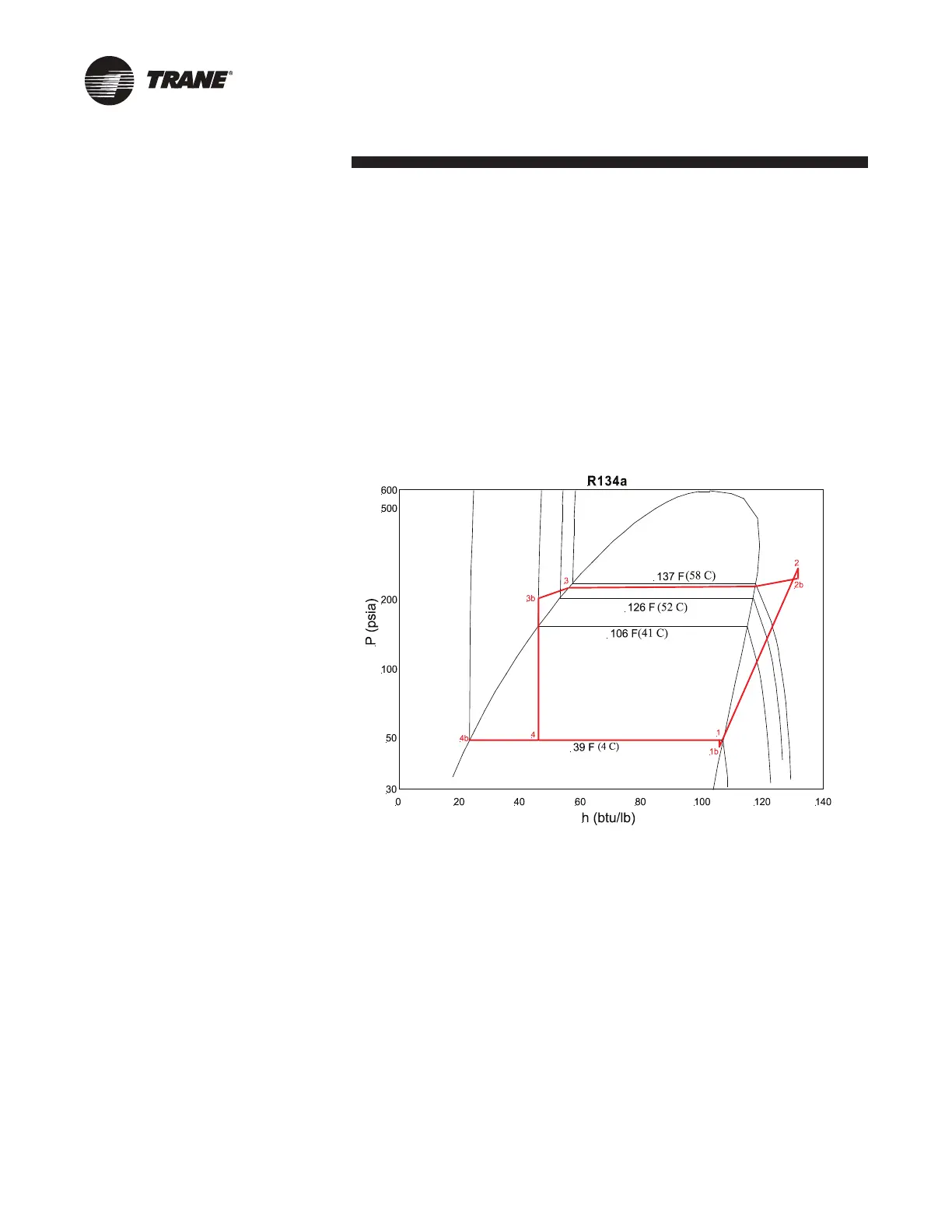

Refrigeration Cycle

The refrigeration cycle of the RTAC

chiller is similar to that of the RTAA air

cooled water chiller. The exception is

that the evaporating and condensing

temperatures have been increased to

allow for optimization of the chiller and

reduced foot print. The refrigeration

cycle is represented in the pressure

enthalpy diagram in Figure 33. Key state

points are indicated on the gure. The

cycle for the full load ARI design point is

represented in the plot.

Fig. V-01 – Pressure Enthalpy (P-h) diagram of RTAC chillercircuito

The RTAC chiller uses a shell and

tube evaporator design with refrigerant

evaporating on the shell side and water

owing inside tubes having enhanced

surfaces (states 4 to 1). The suction

lines and bolt pads are designed to

minimize pressure drop.(states 1 to 1b).

The compressor is a twin-rotor helical

rotary compressor designed similarly to

the compressors offered in other Trane

Screw Compressor Based Chillers

(states 1b to 2).

The discharge lines include a highly

efcient oil separation system that

virtually removes all oil from the

refrigerant stream going to the heat

exchangers (states 2 to 2b). De-

superheating, condensing and

sub-cooling is accomplished in a n

and tube air cooled heat exchanger

where refrigerant is condensed in the

tube (states 2b to 3b). Refrigerant ow

through the system is balanced by an

electronic expansion valve (states 3b to

4).

Operating Principles

Loading...

Loading...