EN - T8

-15-

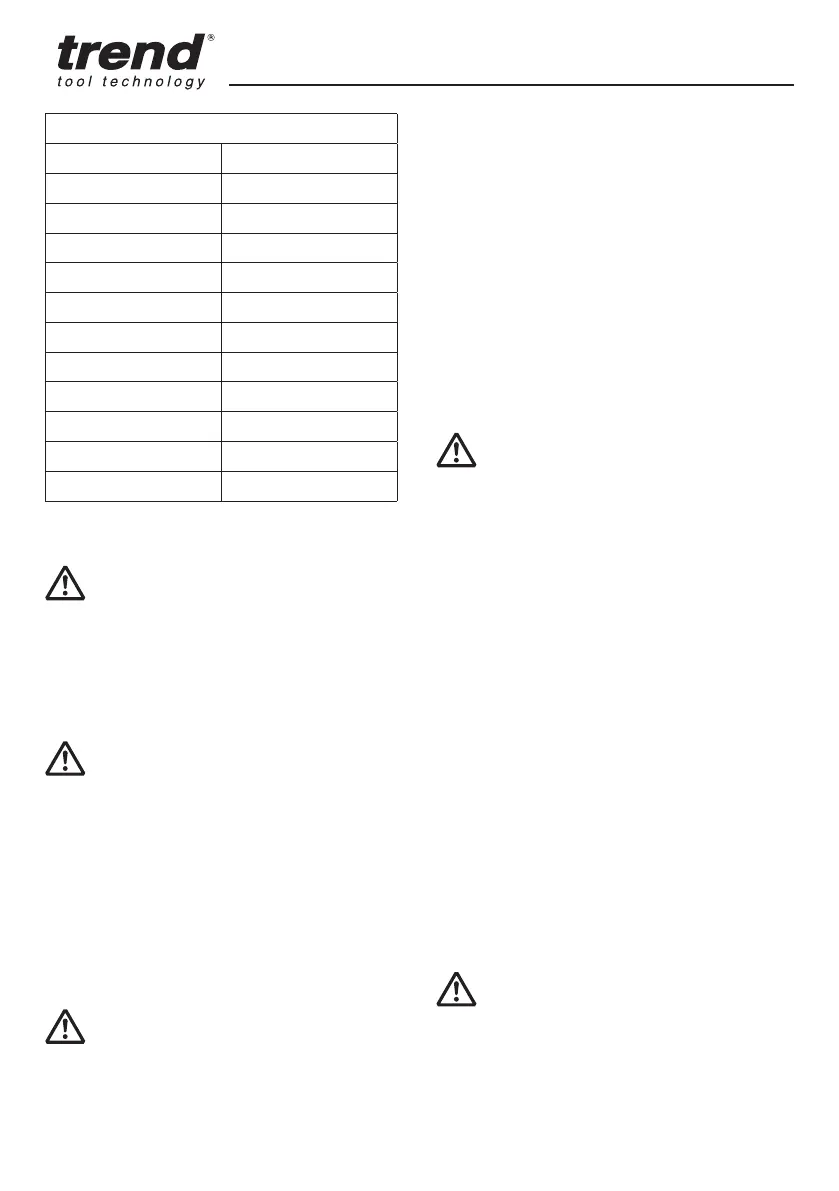

SPEED SELECTION CHART

DIAL SETTING APPROXIMATE RPM

1 10,000

2 11,500

3 13,000

4 14,500

5 16,000

6 18,000

7 20,000

8 21,500

9 23,000

10 24,000

Max 26,000

The speeds in this chart are approximate and are for

reference only. Your router may not produce the exact

speed listed for the dial setting.

WARNING: Always follow the cutter

manufacturer’s speed recommendations as some

bit designs require specific speeds for safety or

performance.

If you are unsure of the proper speed or are experiencing

any type of problem, contact the cutter manufacturer.

LED Worklights - (Fig. F)

CAUTION: Do not stare into worklight.

Serious eye injury could result.

Two LED worklights (57) are located next to the collet

assembly (6).

1. The worklights (57) will constantly illuminate when the

router is connected to the mains power supply.

2. To switch off the worklights the router must be

disconnected from mains power supply.

NOTE: The worklight is for lighting the immediate work

surface and is not intended to be used as a flashlight.

Moulding Natural Timbers

WARNING: When routing always lock the

plunge locking lever.

When edge moulding natural timbers, always mould the

end grain first, followed by the long grain. This ensures

that if there is breakout, it will be removed when the long

grain is routed.

Adjusting the Depth of Cut - (Fig. A, E)

1. Place the router with cutter fitted on to the workpiece.

2. Set the depth stop turret (7) as required.

3. Loosen the locking knob (4) securing the depth stop (3).

4. Lower the router slowly until the cutter touches the

workpiece and secure it in place by locking the plunge

with the plunge locking lever (16).

5. Set the required depth by adjusting the distance

between the bottom of the depth stop and the depth

stop turret.

6. Tighten the locking knob to secure the depth stop.

NOTE: By rotating the depth stop turret, eight depth

settings can be quickly made.

Direction Of Feed - (Fig. L)

WARNING: Avoid climb-cutting (cutting in

direction opposite than shown in Fig. L). Climb-cutting

increases the chance for loss of control resulting in

possible injury. When climb-cutting is required (backing

around a corner), exercise extreme caution to maintain

control of router. Make smaller cuts and remove minimal

material with each pass.

The direction of feed is very important when routing and

can make the difference between a successful job and

a ruined project. Fig. L show proper direction of feed for

most cuts.

1. When routing along an edge, the direction of the

router travel should be against that of the rotation of

the cutter. This will create the correct cutting action

and prevent the cutter from snatching. It will also pull

the router towards the workpiece and the side fence or

guide bearing will be less likely to wander from the edge

of the workpiece.

Feed Speed

The speed at which the cutter is fed into the wood must

not be too fast that the motor slows down, or too slow

that the cutter leaves burn marks on the face of the

wood.

NOTE: Practice judging the speed by listening to the

sound of the motor when routing.

Using a Side Fence - (Fig. M)

CAUTION: Ensure working position is

comfortable and at a suitable working height.

1. Ensure the wing bolts (28) are fully released. Slide the

guide rods (26) into the routing base (8) and tighten the

wing bolts.

2. Adjust the fence fine adjustment knob (29) to the required

distance and clamp in place with the wing bolts (28).

Loading...

Loading...