EN - T8

-14-

Using the Router - (Fig. A, L)

CAUTION: Turn the router on before plunging

the cutter head into the workpiece.

CAUTION:

• Excessive cutting may cause overload of the motor

or difficulty in controlling the tool, the depth of cut

should not be more than 15mm at a pass when cutting

grooves with a 8mm diameter bit.

• When cutting grooves with a 20mm diameter bit, the

depth of cut should not be more than 5mm at a pass.

• For extra deep grooving, make two or three passes

with progressively deeper bit settings.

CAUTION: After long periods of working at

low speeds, allow the machine to cool down by running

it for three minutes at maximum speed, with no load.

All common routing tasks can be performed with the

plunge cut router on all types of wood and plastic:

• Grooving

• Rebating

• Recessing

• Veining

• Profiling

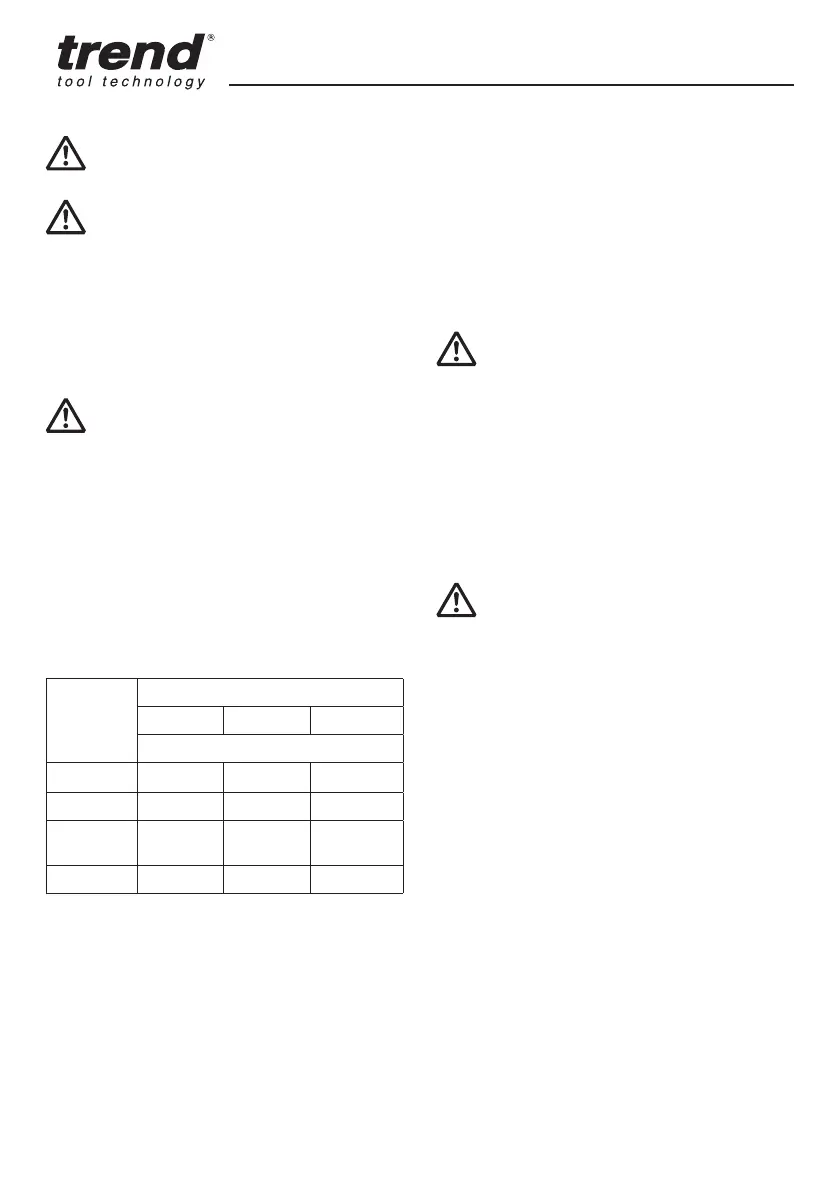

To prevent overload of the tool by using the wrong speed

selection, follow the recommended settings below:

MATERIAL CUTTER DIAMETER

10 – 30mm 30 – 50mm 50 – 65*mm

SPEED SELECTION

Hardwood 11 - 5 6 - 2 5 - 2

Softwood 11 - 6 11 - 5 5 - 2

Chipboard

Faced

11 - 6 11 - 4 n / a

Plastic 11 - 5 11 - 4 n / a

* Do not use cutters larger than 50mm unless the router

is fitted in a router table.

NOTE: Only carbide tipped cutters should be used on

panels faced with plastic laminates. The hard laminates

will quickly dull steel cutters.

NOTE: For better plunge sliding movement, frequently

clean the columns of dust or debris. If the plunging

movement is not moving as smooth as desired, lubricate

the columns with a dry Teflon lubricant.

1. After setting the cutting depth as described, locate the

router such that the cutter is directly over the place you

will be cutting.

2. With the router running, lower the unit smoothly down

into the workpiece. DO NOT JAM THE ROUTER DOWN.

3. When the tool reaches the pre set depth, turn the

plunge locking lever (16) to lock.

4. When you have finished routing, push the plunge

locking lever (16) to unlock and let the spring lift the

router directly out of the workpiece.

5. Always feed the router opposite to the direction in

which the cutter is rotating. Refer to Fig. L.

On/Off Trigger Switch - (Fig. A)

WARNING: To reduce the risk of serious

personal injury, turn unit off and disconnect it from power

source before making any adjustments or removing/

installing attachments or accessories. An accidental

start-up can cause injury.

1. To turn the unit on, press the trigger release button

(20) and then squeeze the on/off trigger switch (19).

Continue to squeeze the trigger switch for continuous

running.

2. To turn the unit off release the trigger.

Variable Speed Dial - (Fig. A)

WARNING: If the speed control ceases

to operate, or is intermittent, stop using the tool

immediately. Please contact Trend Tool Technology Ltd

or authorized service facility for repair.

NOTICE: The router is equipped with electronics to

monitor and maintain the speed of the tool while cutting.

In low and medium speed operation, the speed control

prevents the motor speed from decreasing. If you expect

to hear a speed change and continue to load the motor,

you could damage the motor by overheating. Reduce

the depth of cut and/or slow the feed rate to prevent tool

damage.

Refer to the Speed Selection Chart to choose a router

speed. Turn the speed dial (1) to control router speed.

The lowest speed is 10,000 and the highest speed is

26,000 rpm using the speed dial (1).

1. Turn the speed dial to the required position. The dial

is numbered from 1 – Max. and corresponds to router

speeds of 10,000 rpm to 26,000 rpm.

2. Use the slower settings for large diameter cutters and

the faster settings for small diameter cutters.

3. The correct setting will also depend on the density of

the material, depth of cut and feed speed of the router.

NOTE: A noticeable loss of motor rpm means motor

overload

Loading...

Loading...