13/19

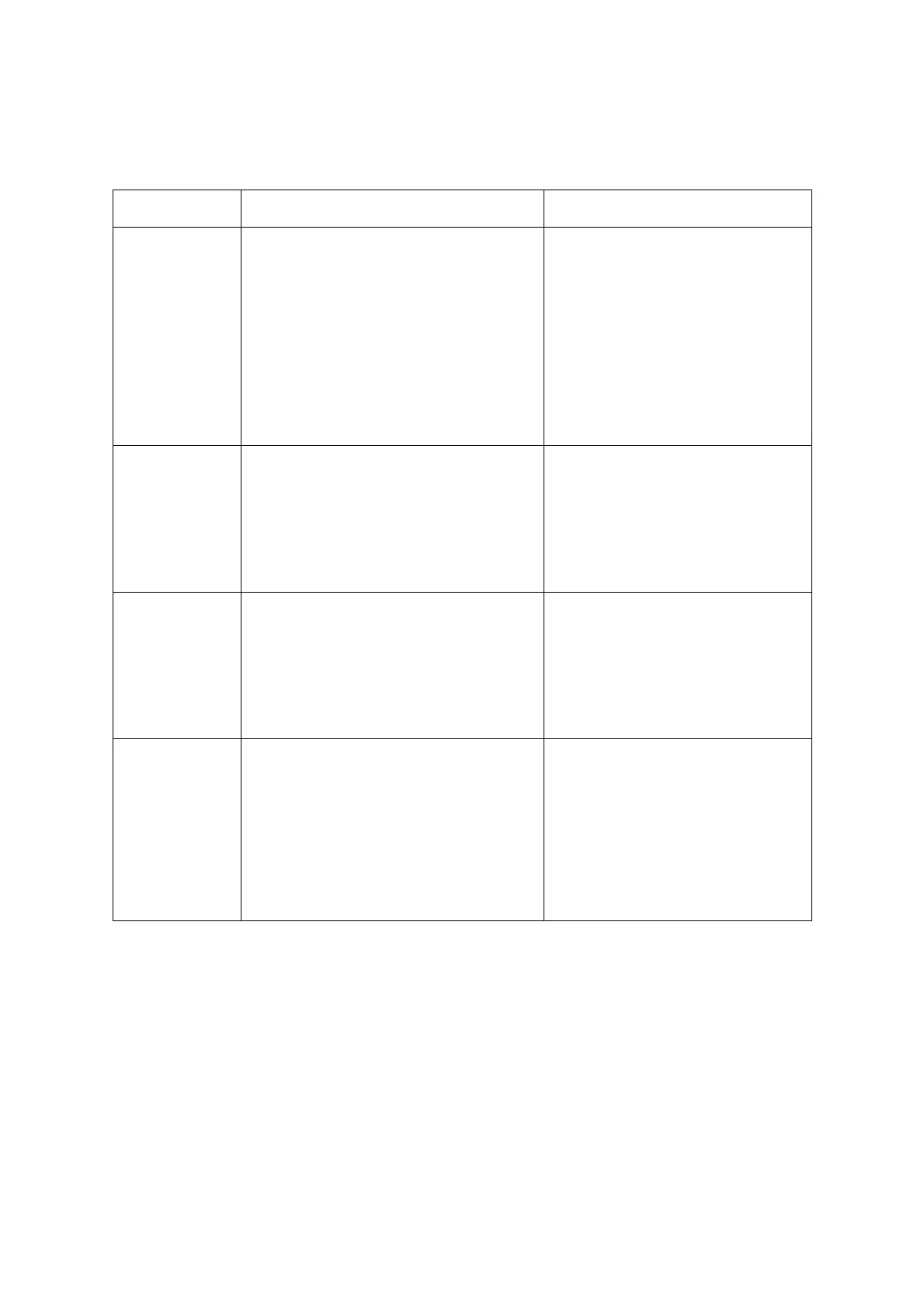

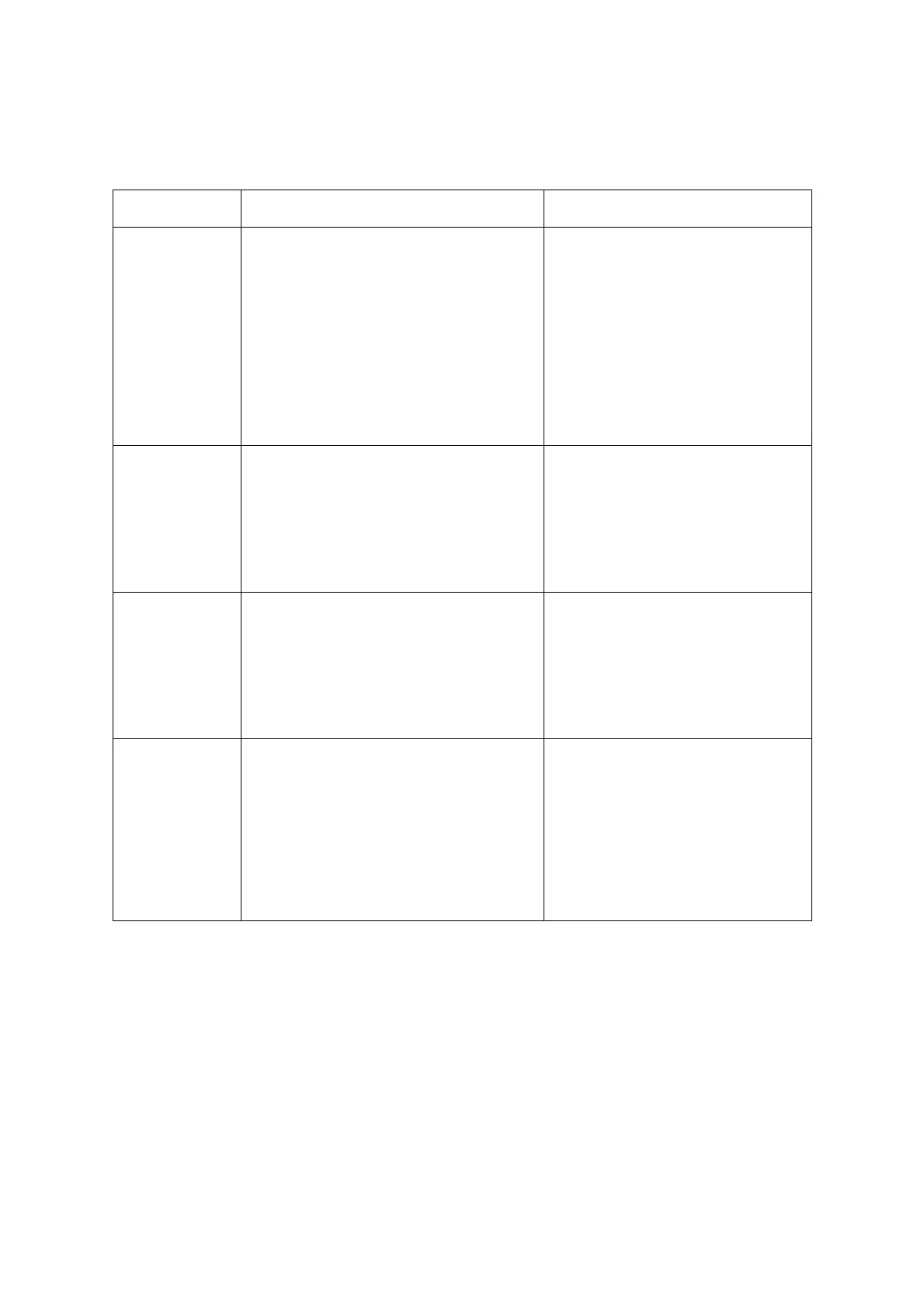

CHAPTER8.TROUBLESHOOTING

Problems Possiblecauses Solution

Tooweakstriking 1.Enginerotationspeedlow.

2.GaspressuretoolowinN2Chamber.

3.GaspressuretoolowinAccumulator.

4.Setwrongpressure,oroverflowvalvebroken.

5.Chiselbroken.

6.HydraulicOilnotenoughornotclean

1.Regulateit.

2.Checkandrecharge.

3.Checkandrecharge.

4.Checkandregulate.

5.Grindthedamagesofchiselorbushing.

6.Check,addorchangenewoil

Nostriking 1.Wrongpressureofoverflowvalve.

2.GaspressuretoohighinN2chamber.

3.Oilleakstochamber.

4.Cylinder,pistonorvalvesdamaged.

1.Regulatetoproperpressure.

2.Regulatetoproperpressure.

3.Replaceoilseal.

4.Repairsurfacebyabrasivepaper.

Unsteadystriking 1.GaspressuretoohighinN2chamber.

2.Pressurelowofoverflowvalve.

3.Chiselorbushdamaged.

4.Cylinder,pistonorvalvesdamaged.

1.Regulatetoproperpressure.

2.Regulatetoproperpressure.

3.Grindtorepairthedamagedpart.

4.Repairsurfacebyabrasivepaper.

Nitrogenleaks 1.Inletleaks.

2.Airvalveleaks.

3.N2chamberleaks.

4. Dismantle the oil‐return hose, if air bubble

existsintheoil,meansairsealdamaged.

1.ReplacebushingOsealring.

2.ReplacevalveOsealring.

3.Fastenthethroughbolts.

4.Replacetheseal.

Loading...

Loading...