Operating Manual – IDE 30 / 50 / 60

B - 8

EN

16. Troubleshooting

m Danger to life due to improper repair! Do no

attempt to carry out modifications or repairs

on the device. Any unauthorised modifica-

tion may result in serious injuries or even

death. Have repairs carried out by a certified

specialist workshop.

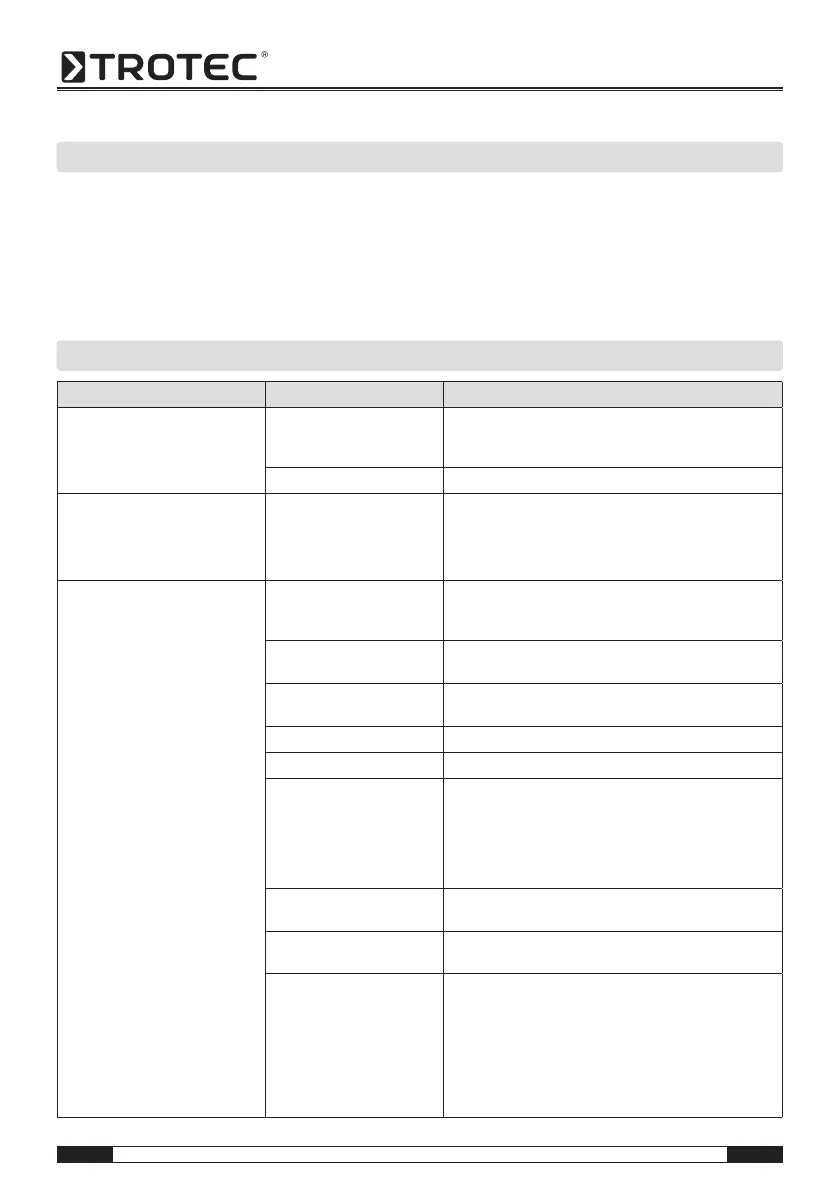

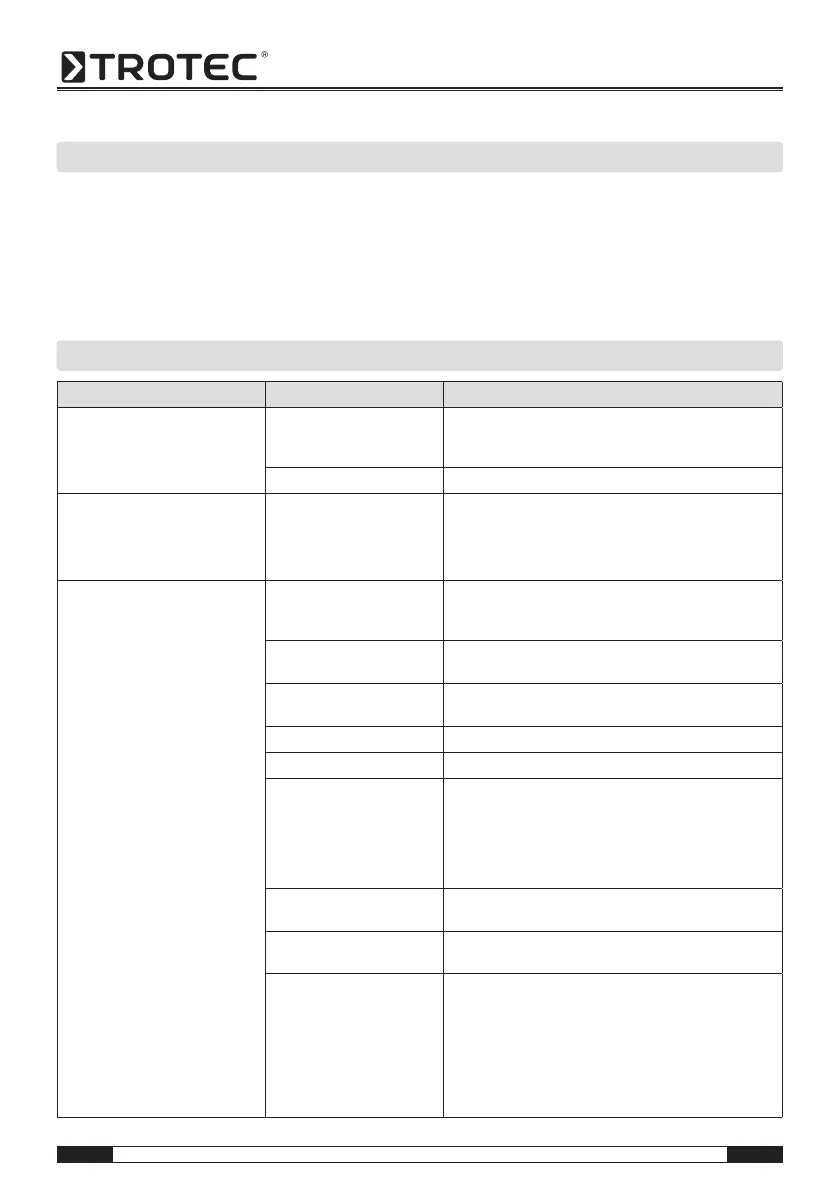

17. Singling out problems

Problem Cause Error correction

Fan does not start running and flame

is not ignited

Control device is incorrectly set • Check if the control equipment is correctly set (e. g. the

temperature set at the thermostat must be higher than the

room temperature).

Control device defective • Have the control device replaced by the customer service.

Fan does not start running or switch-

es off during start-up or operation

no power supply • Check the characteristics of the electrical system

(230 V -1~ - 50 Hz).

• Check the function and position of the selector switch.

• Check if the fuse is intact.

Fan switches off during start-up or

operation

Flame is present prior to the

ignition of the transformer

• Contact the customer service and have the device cleaned

and heating oil residues removed from the combustion

chamber.

Photoelectric cell defective • Have the photoelectric cell replaced by the customer ser-

vice

Motor winding interrupted or

blown

• Have the motor replaced by the customer service

Motor bearing blocked • Have the motor bearing replaced by the customer service.

Motor capacitor blown • Have the motor capacitor replaced by the customer service

no ignition • Check the connections of the ignition cables to the elec-

trodes and the transformer.

• Check the position and the distance of the electrodes.

• Check if the electrodes are clean.

• Have the transformer replaced by the customer service.

Flame control system defective • Have the flame control equipment replaced by the customer

service.

Photoelectric cell defective • Have the photoelectric cell cleaned or replaced by the cus-

tomer service.

Burner is not or only insuffi-

ciently supplied with heating

oil

Contact the customer service in order to:

• have the integrity of the coupling between the pump and

motor checked.

• have the heating oil circuit checked for air that may have

entered the circuit and to have the tightness of the lines

and filter seal checked.

• have the nozzle cleaned or replaced.

Loading...

Loading...