Maintenance/Repairs

REPAIRING

A

DAMAGED

SHREDDER

SCREEN

Periodically inspect the screen for

cracks or bent parts.

• Discard a screen that is cracked.

• A slightly bent crossbar will not

adversely affect operation.

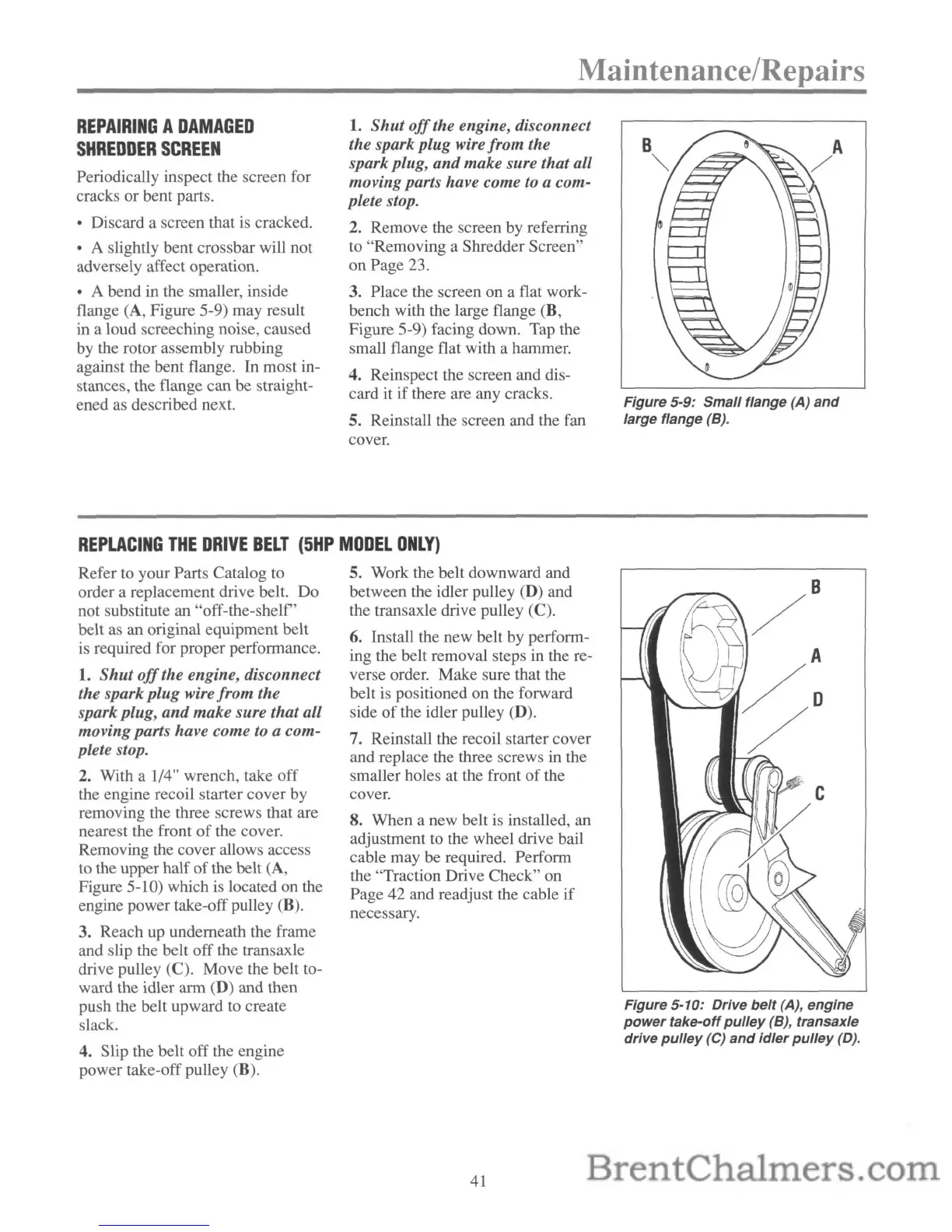

• A bend in the smaller, inside

flange (A, Figure 5-9) may result

in a loud screeching noise, caused

by the rotor assembly rubbing

against the bent flange. In most in-

stances, the flange can be straight-

ened as described next.

1.

Shut

off

the engine, disconnect

the spark plug wire from the

spark plug,

and

make sure that all

movingparts have come

to

a com-

plete stop.

2. Remove the screen by referring

to "Removing a Shredder Screen"

on

Page 23.

3. Place the screen on a flat work-

bench with the large flange (B,

Figure 5-9) facing down. Tap the

small flange flat with a hammer.

4. Reinspect the screen and dis-

card it if there are any cracks.

S.

Reinstall the screen and the fan

cover.

Figure 5-9: Small flange (A)

and

large flange (B).

REPLACING

THE

DRIVE

BELT

(5HP

MODEL

ONLY)

Refer to your Parts Catalog to

order a replacement drive belt. Do

not substitute an "off-the-shelf'

belt as an original equipment belt

is required for proper performance.

1.

Shut

off

the engine, disconnect

the spark

plug

wire

from

the

spark plug,

and

make sure that all

movingparts have come to a com-

plete stop.

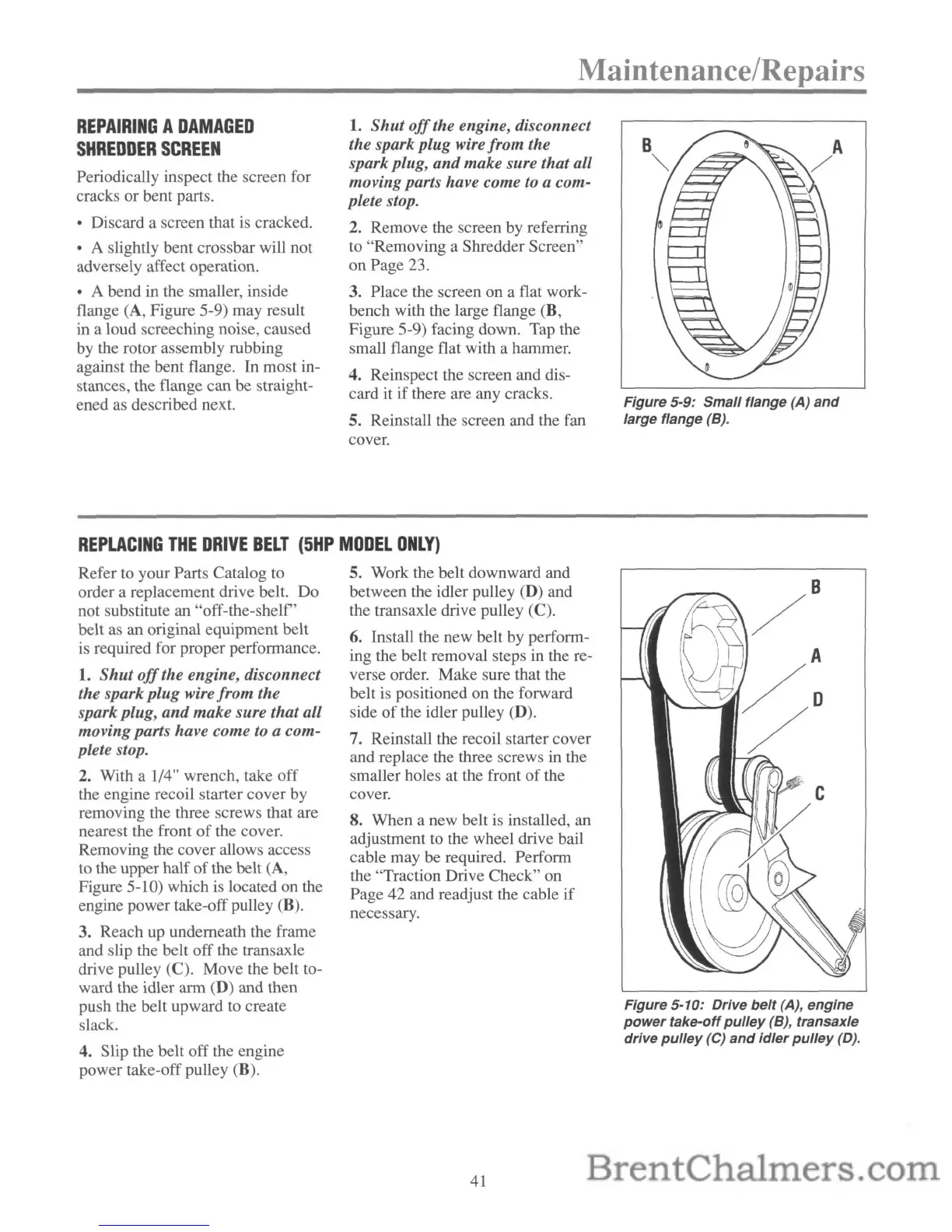

2.

With a 1/4" wrench, take

off

the engine recoil starter cover by

removing the three screws that are

nearest the front

of

the cover.

Removing the cover allows access

to the upper half

of

the belt (A,

Figure 5-10) which is located on the

engine power take-off pulley (B).

3. Reach up underneath the frame

and slip the belt

off

the transaxle

drive pulley

(C). Move the belt to-

ward the idler arm (D) and then

push the belt upward to create

slack.

4. Slip the belt off the engine

power take-off pulley (B).

S.

Work the belt downward and

between the idler pulley (D) and

the transaxle drive pulley

(C).

6. Install the new belt by perform-

ing the belt removal steps in the re-

verse order. Make sure that the

belt is positioned on the forward

side

of

the idler pulley (D).

7. Reinstall the recoil starter cover

and replace the three screws in the

smaller holes at the front

of

the

cover.

8. When a new belt is installed, an

adjustment to the wheel drive bail

cable may be required. Perform

the "Traction Drive Check" on

Page 42 and readjust the cable

if

necessary.

41

Figure 5-10: Drive

belt

(A), engine

power

take-offpUlley (B), transaxle

drive

pulley

(e)

and

idler

pulley

(D).

Loading...

Loading...