TIPS FOR BEST TRIMMING RESULTS

• For best trimming results, operate unit at full throttle.

• Keep the cutting attachment parallel to the ground.

• Do not force the cutting attachment. Allow the tip of the line to do the cutting,

especially along walls. Cutting with more than the tip will reduce cutting

efficiency and may overload the engine.

• Cut grass over 8 inches (200 mm) by working from top to bottom in small increments

to avoid premature line wear or engine drag.

• Slowly move the trimmer into and out of the cutting area at the desired height. Move

either in a forward-backward or side-to-side motion.

Cutting shorter lengths produces the best results.

• Trim only when grass and weeds are dry.

• The life of your cutting line is dependent upon:

• Proper adherence of explained trimming techniques

• What vegetation is cut

• Where vegetation is cut

For example, the line will wear faster when trimming against

a foundation wall as opposed to trimming around a tree.

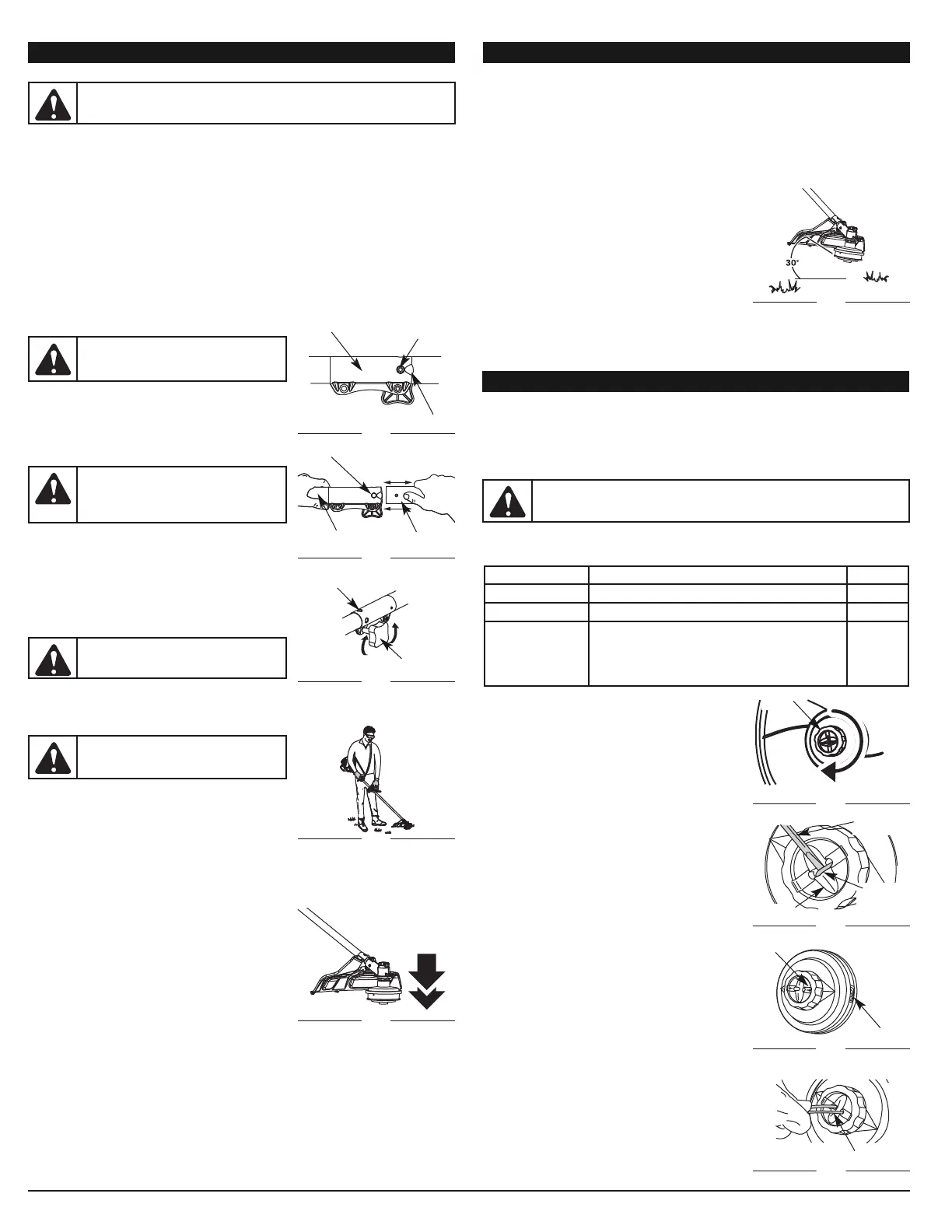

DECORATIVE TRIMMING

Decorative trimming is accomplished by removing all vegetation around trees, posts,

fences and more.

Rotate the whole unit so that the cutting attachment is at a 30° angle to the ground (Fig. 18).

OPERATING INSTRUCTIONS

MAINTENANCE AND REPAIR INSTRUCTIONS

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency stated in the table.

These procedures should also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or skills. If you are

unsure about these procedures take your unit to any non-road engine repair

establishment, individual or authorized service dealer.

NOTE: Maintenance, replacement, or repair of the emission control devices and

system may be performed by any non-road engine repair establishment,

individual or authorized service dealer.

WARNING:

To prevent serious injury, never perform maintenance or

repairs with unit running. Always service and repair a cool unit. Disconnect

the spark plug wire to ensure that the unit cannot start.

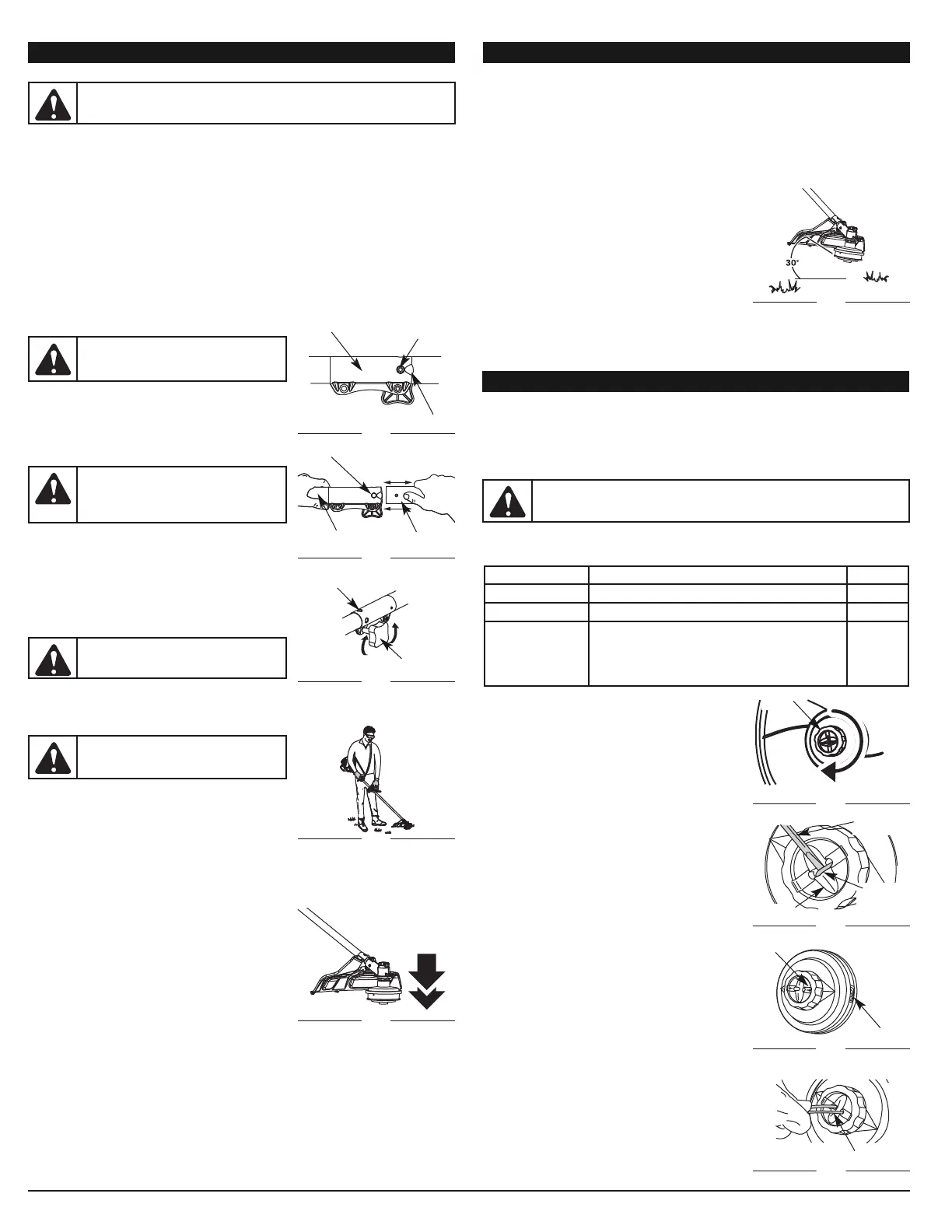

REMOVING THE LINE

1. Rotate the bump knob clockwise until all line is

inside the cutting head (Fig. 19).

2. Using a flat-head screwdriver, insert the tip into the

line dimple and just under the exposed portion of

the line (Fig. 20)

3. Pull the line straight out until all line is removed from

the cutting head.

LINE INSTALLATION

Always use original equipment manufacturer 0.095 in.

(2.41 mm) replacement line.

1. Align the arrows on the bump knob with the spool

cover eyelets, if they are not already (Fig. 21).

2. Using 16 ft. (3.2 m) of 0.095 in. (2.41 mm) replacement

line push both ends of the line through the holes in the

bump knob until they protrude through the eyelets on

both sides of the cutting head. Continue pulling the line

until approximately 6 ft. (1.5 m) is visible from both

sides of the cutting head. (Fig. 22)

3. Hold the spool cover, turn the bump knob clockwise

to wind the line around the spool until about 5 in.

(12.7 cm) is protruding from each side of the cutting

head. (Fig. 19)

4. Start the unit and bump the cutting head on the

ground until the desired cutting length is achieved.

Excess line will be trimmed off by the line blade.

NOTE: If the cutting line ends are pulled into the

cutting head or the line becomes twisted,

refer to Removing the Line.

5

Flat-Head

Screw Driver

Arrows

Trimmer

Line

Dimple

Eyelet

Trimmer line

OPERATING THE EZ-LINK™ SYSTEM

The EZ-Link™ system enables the use of these optional Add-Ons:

Mach 4® Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AF720

Hedge Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AH720

Brushcutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BC720*

Blower/ Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BT720

Blower Vacuum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BV720

Cultivator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GC720

Edger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LE720

Pole Saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PS720

Straight Shaft Trimmer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SS725

Snow Thrower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ST720

Turbo Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TB720

*Do NOT use this attachment with an electric powered unit.

Removing the Cutting Attachment or Add-On

1. Turn the knob counterclockwise to loosen (Fig. 15).

2. Press and hold the release button (Fig. 13).

3. While firmly holding the upper shaft housing, pull the

cutting attachment or add-on straight out of the EZ-

Link™ coupler (Fig. 14).

Installing the Cutting Attachment or Add-On

NOTE:

Place the unit on the ground or on a work bench

to make add-on installation or removal easier.

1. Turn knob counterclockwise to loosen (Fig. 15).

2. While firmly holding the add-on, push it straight into

the EZ-Link™ coupler (Fig. 14).

NOTE: Aligning the release button with the guide

recess will help installation (Fig. 13).

3. Turn the knob clockwise to tighten (Fig. 15).

For edging (when using the line head cutting attachment

with EZ-Link™ models), lock the release button of the cutting attachment into the 90° edging

hole (Fig. 15).

HOLDING THE TRIMMER

Before operating the unit, stand in the operating

position (Fig. 16). Check for the following:

• The operator is wearing eye protection and proper

clothing

• With a slightly-bent right arm, the operator’s right

hand is holding the shaft grip

• The operator’s left arm is straight, the left hand holding the handle

• The unit is at waist level

• The cutting attachment is parallel to the ground and easily contacts the grass without

the need to bend over

ADJUSTING TRIMMING LINE LENGTH

The cutting head allows you to release trimming line

without stopping the engine. To release more line, lightly

tap the cutting attachment on the ground (Fig. 17) while

operating the trimmer at high speed.

NOTE: Always keep the trimming line fully extended.

Line release becomes more difficult as the

cutting line becomes shorter.

Each time the head is bumped, about 1 inch (25.4 mm)

of trimming line is released. A blade in the cutting attachment shield will cut the line to the

proper length if excess line is released.

For best results, tap the cutting head on bare ground or hard soil. If line release is

attempted in tall grass, the engine may stall. Always keep the trimming line fully

extended. Line release becomes more difficult as the cutting line becomes shorter.

NOTE: Do not rest the cutting head on the ground while the unit is running.

Some line breakage will occur from:

• Entanglement with foreign matter

• Normal line fatigue

• Attempting to cut thick, stalky weeds

• Forcing the line into objects such as walls or fence posts

WARNING:

Before you begin using any attachment, read and

understand the manual that came with the attachment. Follow all safety

information contained within.

WARNING:

To avoid serious personal

injury and damage to the unit, shut the unit

off before removing or installing add-ons.

CAUTION:

Lock the release button in

the primary hole and securely tighten the

knob before operating this unit.

CAUTION:

Add-ons are to be used in

the primary hole only. Using the wrong

hole could lead to personal injury or

damage to the unit.

Guide Recess

Fig. 13

Release

Button

EZ-Link

™

Coupler

Upper Shaft

Housing

Fig. 14

Lower Shaft

Housing

Primary Hole

Knob

Fig. 15

90˚ Edging Hole

(Trimmer Only)

OPERATING INSTRUCTIONS

Bump

Knob

WARNING:

Always wear eye, hearing,

foot and body protection to reduce the

risk of injury when operating this unit.

Fig. 16

FREQUENCY MAINTENANCE REQUIRED SEE

Every 10 hours Clean and oil air filter p. 6

Change 1st 10 hours Change oil p. 6

Every 40 hours

Change oil

Clean spark arrestor and change oil

Check rocker arm to valve clearance and adjust

Check spark plug condition and gap

p. 6

p. 6

p. 6

p. 6

Fig. 17

Fig. 22

Fig. 21

Fig. 20

Fig. 19

Fig. 18

Loading...

Loading...