9

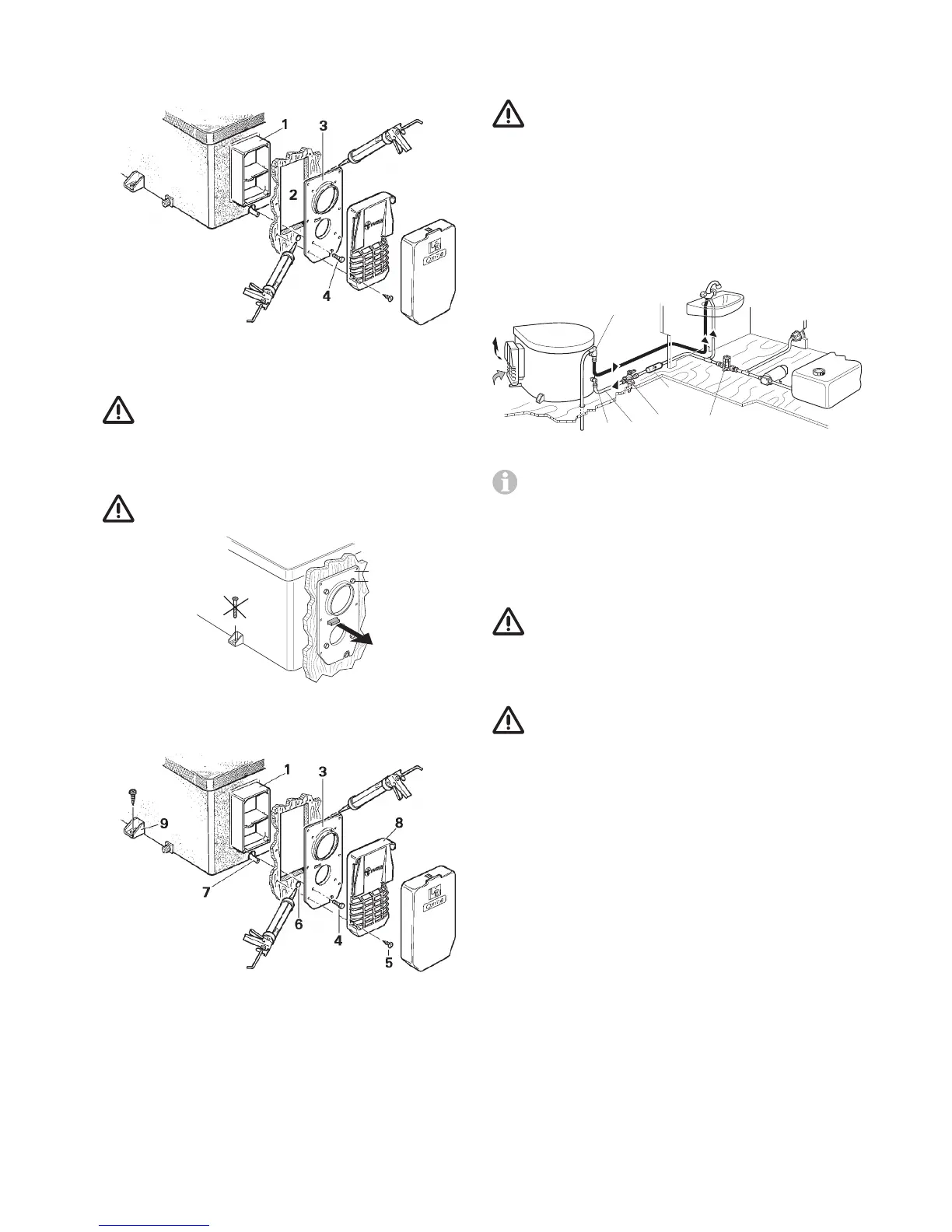

Water connection

All pressure and submergible waterpumps can be used for

operating the water heater.

In order to guarantee complete emptying of the

water content and to prevent pressures of greater

than 400 kPa occurring in the boiler, the enclosed pres-

sure reducer (10), the enclosed water connectors (12 + 13)

and the enclosed safety (pressure relief) drain valve (14)

must be used!

When using pressure pumps with high switching hysteresis,

hot water may flow back through the cold water tap. To pre-

vent the backflow, we recommend that a non-return valve

(nrv – not included in the scope of supply) be fitted between

the outlet to the cold water tap and the drain valve.

14

10

nrv

12

16

Fig.13

The supplied water connectors (12 + 13) and safety/drain

valve (14) have a 12 mm rigid piping connection (e. g.

John Guest System). For connecting to rigid pipes with other

diameters appropiate adapters (not included in scope of deliv-

ery) must be used.

As special accessories Truma supplies the water connectors

(12 + 13) and safety/drain valve (14) with a 10 mm / 3/8" di-

ameter hose nipple (please refer to page 12).

Route water pipes so that they are as short and free of

kinks as possible (hose connections must be secured

using hose clamps – also for cold water! – pressures of up

to 400 kPa can occur in the Safety/drain valve – also with

submergible pumps – because of the heat of the water and

the resulting expansion).

All hot water pipes should be routed in a descending

manner to the safety/drain valve! Otherwise no guaran-

tee of protection from frost!

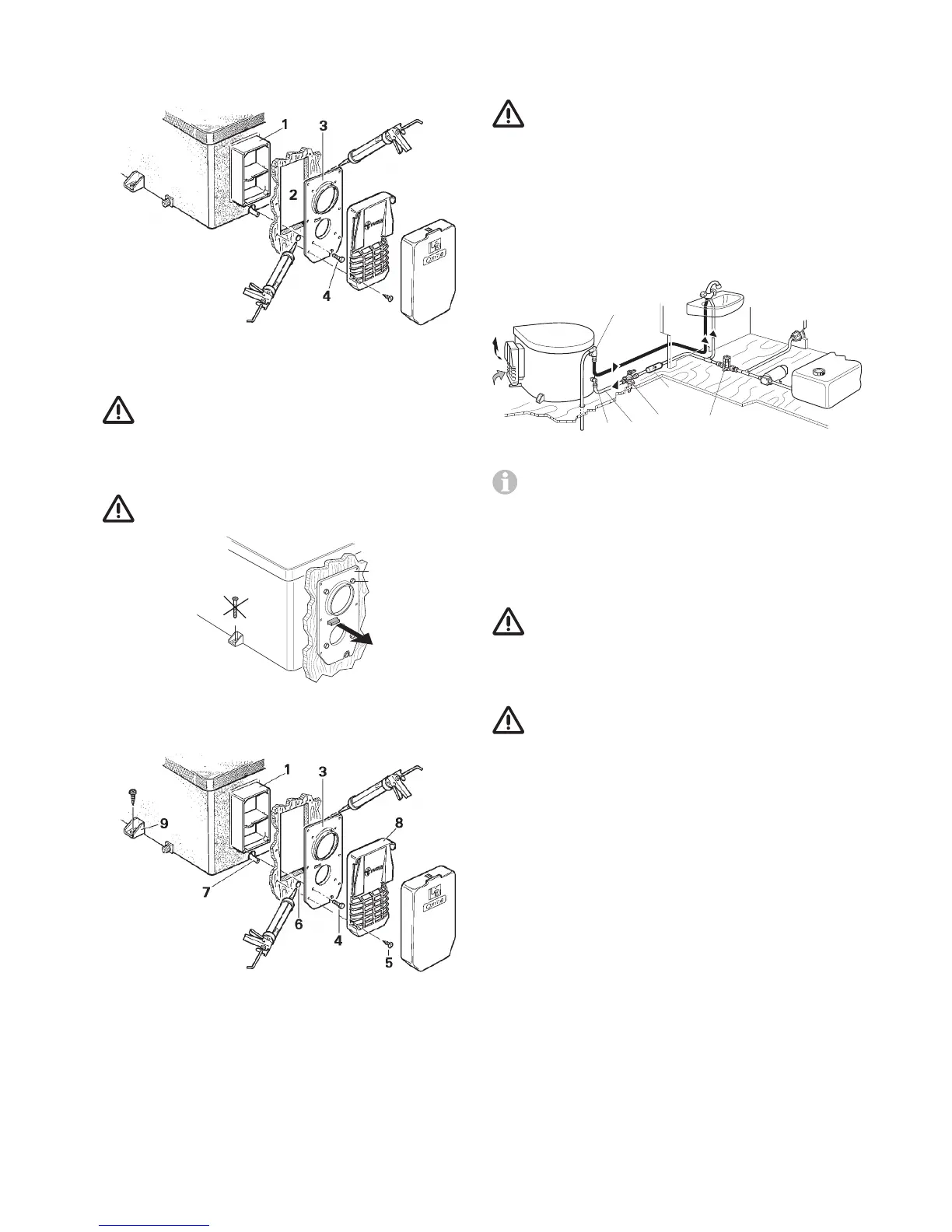

3. Insert heater with cowl body (1) through the wall cutout (2),

allow approx. 5 mm to project out of the wall. Mount sealing

frame (3 – the anti-twisting device ensures correct fitting!).

Pre-drill holes for the 6 fastening bolts (4).

Fig.10

4. Remove sealing frame (3) and coat with non hardening

mastic on the side facing the vehicle – do not use silicone!

The sealing frame must be well sealed with respect to

the front sides and the cross bars of the cowl body (1)

as well as towards the outside wall!

5. Fasten sealing frame (3) to the cowl body using 4 self-cut-

ting screws (4).

Screw the sealing frame (3) in contact together with the

cowl body (1) so the anti-twist device projects out!

4

3

Fig.11

6. Seal the gap between the hole (6) and the condensation

tube (7) with non hardening mastic – do not use silicone!

Fig.12

7. Mount the grille (8). Press the entire cowl assembly onto

the vehicle wall and fasten with 6 screws (5).

8. Screw the boiler securely to the floor of the vehicle with

at least two shackle plates (9) with the screws provided,

B 5.5 x 25, on suitable base (plywood panel, laminated wood

strips or metal base).

Loading...

Loading...