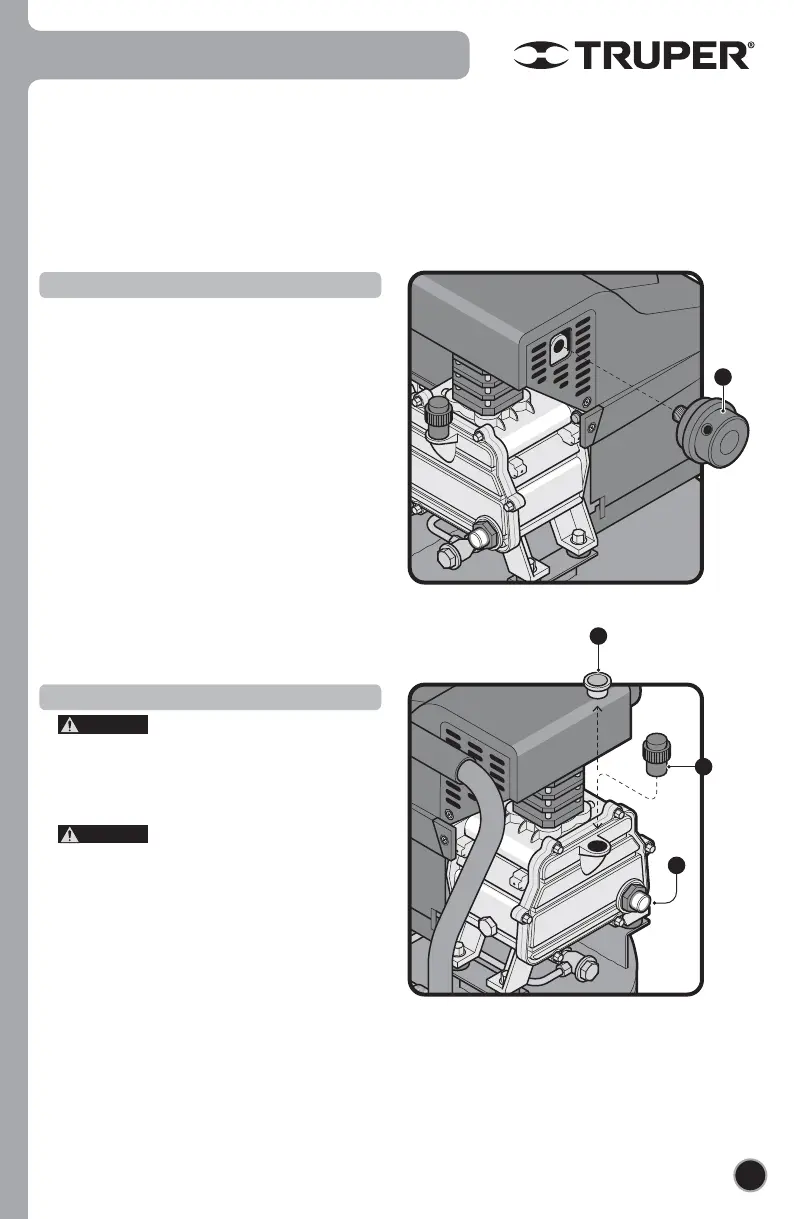

• Screw the air filter (A) aside de carter as indicated in the

image.

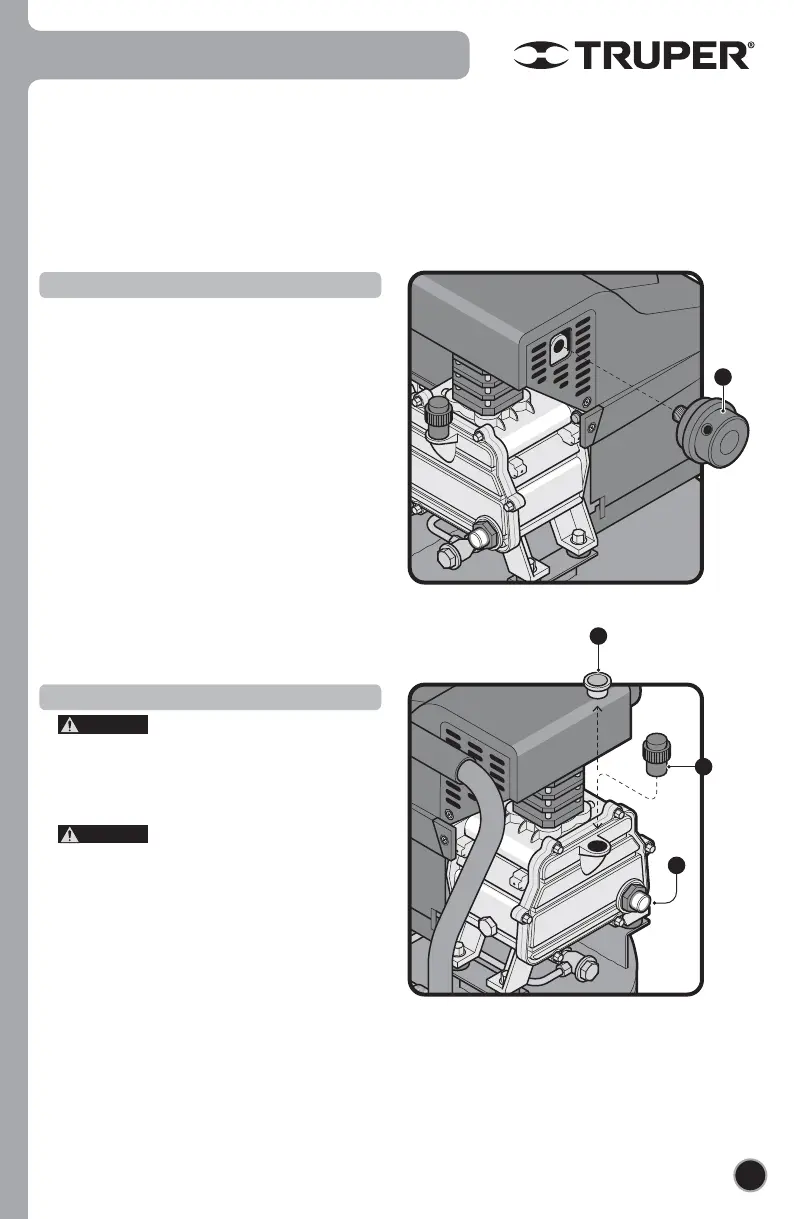

• Replace the transport cap (B) with the

work cap (B

1

) included.

• Check the oil verifying spyhole (C). If oil level is not in

the middle point (red circle), remove the tank cap (B

1

)

and fill up the deposit with compressor lubricating oil

SAE-10W30 up to the indicated level.

• Check the oil level when starting the

job.

• Leave the compressor running a few minutes with the air

valve fully open to allow the correct distribution of the

lubricant.

• The air compressor delivers energy to pneumatic tools as versatile as power tools, therefore, it can be used to drill,

screw, nail, rivet, staple, chisel, polish, torch, clean, paint, etc.

• The compressor is totally automatic, controlled with a pressurestat that stops the motor when the tank pressure reaches

the maximum level and start back when the level is lower to 87 PSI

• The compressor shall be connected into power supply protected with an adequate thermos-differential switch

(thermal-magnetic).

7

Preparation

C

B

A

B

1

Oil

Assembly

CAUTION

CAUTION

ENGLISH

Loading...

Loading...