24 25

Pressurelosswithdieseloil Flowrate(l/min) 306090

Pressureloss(bar) 0.0050.20.4

Accuracyaftercalibration +/-1%

Repeatability (typical) +/-0.3%

Batchtotalreadout 3digitsheight18mm

Totaliserreadout 6digitsheight6mm

Readoutresolution 0.1litri

Connections (inlet/outlet) 1” BSP

Weight (approximate) 1.8Kg

Packagedimensions 185x185x170mm

Optionalfeatures RegistrationinUSgallonsfemale

threadedinlet/outlet1”NPT

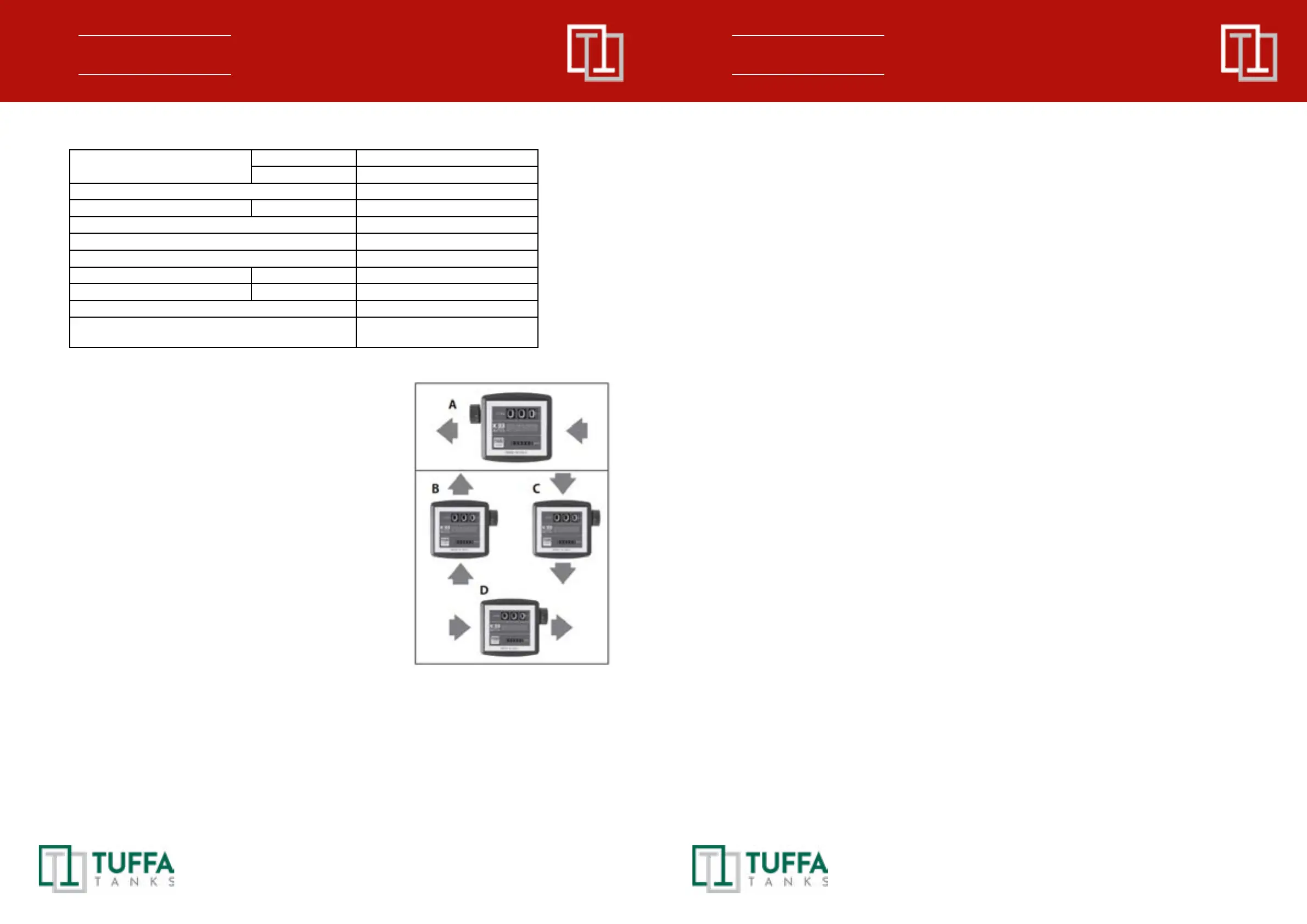

1.3 INSTALLATION

TheK33canbeinstalledinanyposition,onrigidpipelines

orexiblehoses,directlyonpumpsortanks.Themeter

owdirectionisxedandindicatedbyanarrow.The

meterissuppliedinthestandardconguration(A).

Themeterandthecovercanberotatedby90°to90°

inrespecttothebodyinordertocarryoutthedierent

congurationsshown(B,C,D).Theresetknobcanbe

installedeitherontherightsideorontheleftsideof

themeter.Inordertomodifythestandardconguration

followtheinstructionsgiveninsection“Disassembling

/Reassembling”.Themeterbodyisequippedwith4

blindholeswhichcanbethreaded(M5)forapossible

fastening.Ifsolidparticlesenterthemeasuringchamber

thecorrectworkingofthenutatingdiskmaybeaected.

Alwaysltertheuidbyinstallingalteronthemeterinlet

(recommendedlter400µ).

1.4 CALIBRATION

TheK33ispre-calibratedinfactorytobeusedwithDieseloil.Asspecicoperatingconditions

(suchasrealowrate,natureandtemperatureofthemeasureduid)mayaectthemeter

accuracy,are-calibrationshouldbecarriedoutaftertheinstallationhasbeencompleted.A

newcalibrationisnecessaryeachtimethemeterisdisassembledformaintenanceoperations

orwhenitisusedtomeasureuidsthatdierfromDieseloil.

1.4 CALIBRATION PROCEDURE

1.Unscrewtheplug(seediagram1,pos.“14”).

7. OPERATION OF THE SYSTEM

2.Purgethesystem(pump,pipelines,meter)ofairbydispensinguntiltheowstreamisfull

andsteady.

3.Stoptheowbyshuttingothenozzle,butletthepumprunning.

4.Resetthebatchregisterbymeansoftheresetknob(pos.“2”).

5.Dispenseattheowratewhichthebestaccuracyisrequiredat,byusingacalibration

containerhavingacapacitynotlowerthan20litres.Donotreducetheowinordertoreach

thegraduatedzoneofthecalibrationcontainer.Therightmethodistostartandstopthefull

owrepeatedlyuntiltherequiredllingisobtained.

6.Comparetheindicationofthecalibrationcontainer(realvalue)withtheoneofthemeter

(indicatedvalue).

-Iftheindicatedvalueishigherthantherealvalue,loosenthescrew(pos.“12”);

-Iftheindicatedvalueislowerthantherealvalue,tightenthescrew(pos.“12”).

7.Repeattheoperations4to6untilaccuracyissatisfactory.

8.Tightentheplug(pos.“14”)again.TheOringwhichthecalibrationscrewisprovidedwith,

hasthefunctiontoavoidaccidentallooseningoftheadjustmentscrewbutdoesnothaveany

sealingfunctions.Thereforeitisalwaysnecessarytoproperlyxtheplugwiththesealing

gasket(pos.“12”).

1.5 USE

AfterinstallationandcalibrationtheK33isreadytowork.Turntheresetknob(seediagram

1,pos.“12”)(clockwiseifitismountedontheleftofthemeterandanticlockwiseifitismounted

ontheright)untilthebatchregisteriscompletelyreset.Thetotalisercannotberesetinany

way.Makesurethatduringusepressuredoesnotexceedthevalueindicatedinsection

“Technicaldata”.

1.6 USE BY GRAVITY

K33canalsobeusedinfuelunitswhicharenotequippedwithpumpsandwheretheowis

generatedbythedierenceinfuellevelbetweenthetankandthenozzleoutlet.Asareference,

asystemcomposedofatankotheground,withthemeterinstalledrightatthebottomofthe

tank,a3-mlong1’’exiblepipeandamanualnozzletypeSelf2000,guaranteesaowrate

ofapproximately30litres/minuteifthedierenceinlevelishigherthan1.5metres.Longer

pipesornozzlesproducinghigherpressurelossesreducetheowinrespecttotheexisting

dierenceinlevel.Usebygravityisnotrecommendedwithdierencesinlevellowerthan1

metre,astheconsequentreducedowratecausesthemetertoworkoutsideitsguaranteed

accuracyrange.Oneldcalibrationisalwaysadvisableincaseofgravityinstallations.

1.6 MAINTENANCE

NoordinarymaintenanceisrequiredprovidedthatthemeterK33isproperlyinstalledand

used.Anincorrectlteringonthemeterinletmayblockorwearoutthemeasuringchamber,

thusaectingthemeteraccuracy.Shouldthisproblemoccur(seesection“Problem,Causes

andSolutions”)disassemblethemeasuringchamber,asshowninsection“Disassembling/

Reassembling”.

7. OPERATION OF THE SYSTEM

Loading...

Loading...