46 47

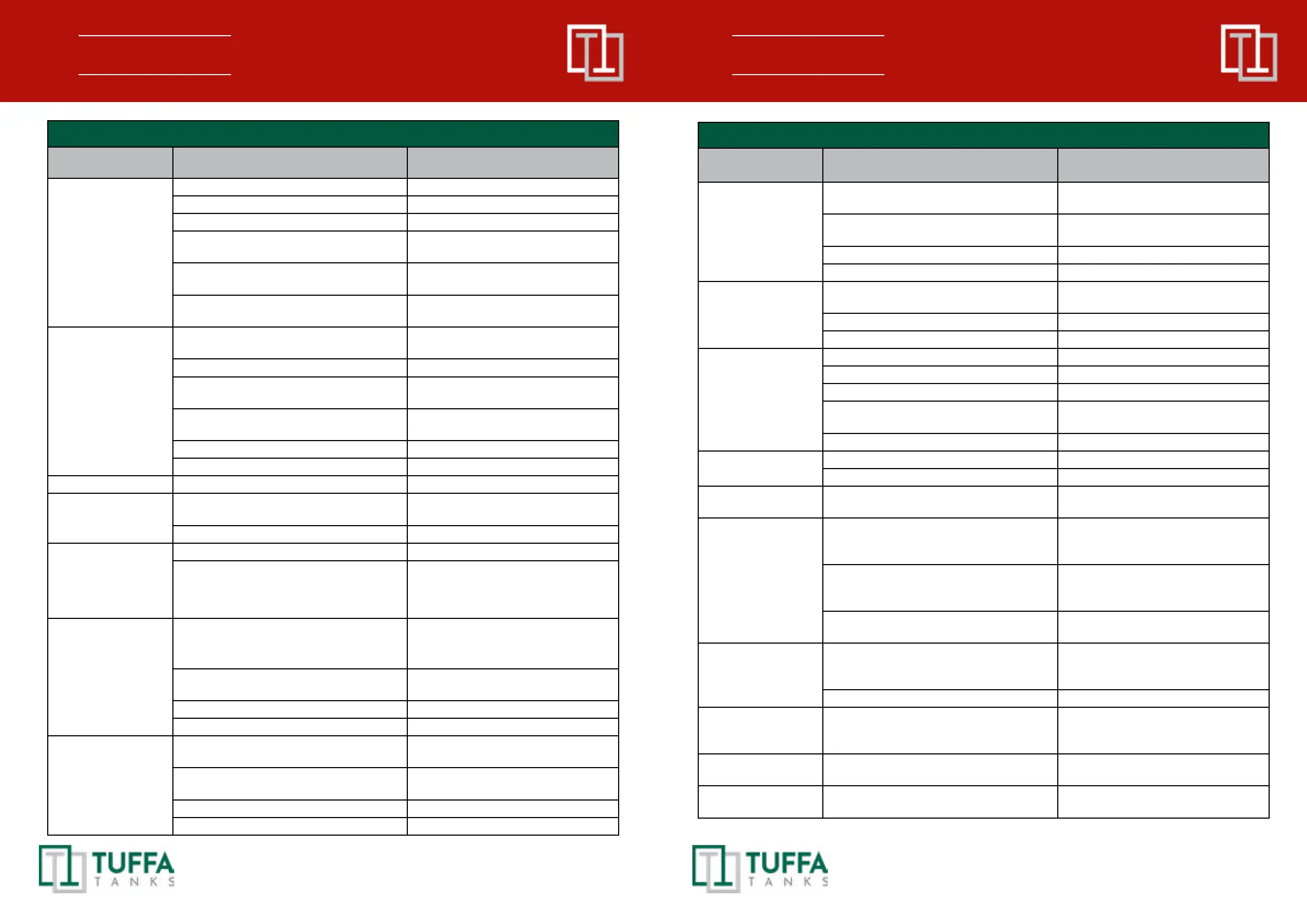

8.4 Troubleshooting

Symptom PossibleCauses Solutions

Nopower 1.Localdistributionboardfuse 1.ChecklocaldistributionboardRCD

2.Powercabledamaged 2.Checkconditionofpowercables

3.Powercableconnectionbroken 3.Checkpowercableconnections

4.Systemcontrolpanelcircuitbreakers 4.Opensystemcontrolpaneland

checkcircuitbreakers

5.Systemcontrolpanelconnections

loose

5.Checkcableconnectionsinsideof

systemcontrolpanel

6.Lowbattery/poorbatteryclip

connection

6.Checkbatterylevel/checkclip

connection

Pumpnotoperating 1.Potentialairlockinpipelinecausedby

tankllafterrunningdry

1.Removenozzleallowingairtopass

throughpipeline

2.Nodieselinthesystem 2.Requestdieseldelivery

3.Pumpcircuitbreakerincontrolpanel

tripped

3.Engagepumpcircuitbreakeror

replaceifnecessary

4.Pumprelayfuseinsystemcontrol

panelblown

4.Replacerelay/fuse

5.Pumpfailure 5.Replacepump

6.Nopowertosystem 6.Checkpowersupply

Slowowrate 1.Blockageinthesystem 1.Replacelterelement

Autonozzlenot

operating

1.Springmechanisminsidenozzlevalve

failed

1.Replacenozzle

2.Triggerplungerfailed 2.Replacenozzle

Nozzleholsternot

switchingpump

correctly(auto

operationnozzle

holsterversionsonly)

1.Microswitchfailure 1.Replacemicroswitch

2.Microswitchlevernotcontacting

correctly

2.Adjustpositionofmicroswitchor

switchlever

Levelgaugedoesnot

showreading

1.Powerfailuretogauge 1.Checkpowersupplyandcable

connections

2.Sensorcableconnectionloose 2.Checksensorcableconnections

insidegaugeunit

3.Sensorfailure 3.Refertomanufacturer

4.Gaugeunitfailure 4.Refertomanufacturer

Levelgaugeshows

incorrectreading

1.Pressuresensornotpositionedatbase

oftank

1.Lowerpressuresensordownuntil

ittouchesbaseoftank

2.Incorrectgaugeparameters 2.Refertomanufacturertoalter

gaugeparameters

3.Sensorfailure 3.Refertomanufacturer

4.Gaugeunitfailure 4.Refertomanufacturer

8. MAINTENANCE OF THE TUFFA TANKS 8. MAINTENANCE OF THE TUFFA TANKS

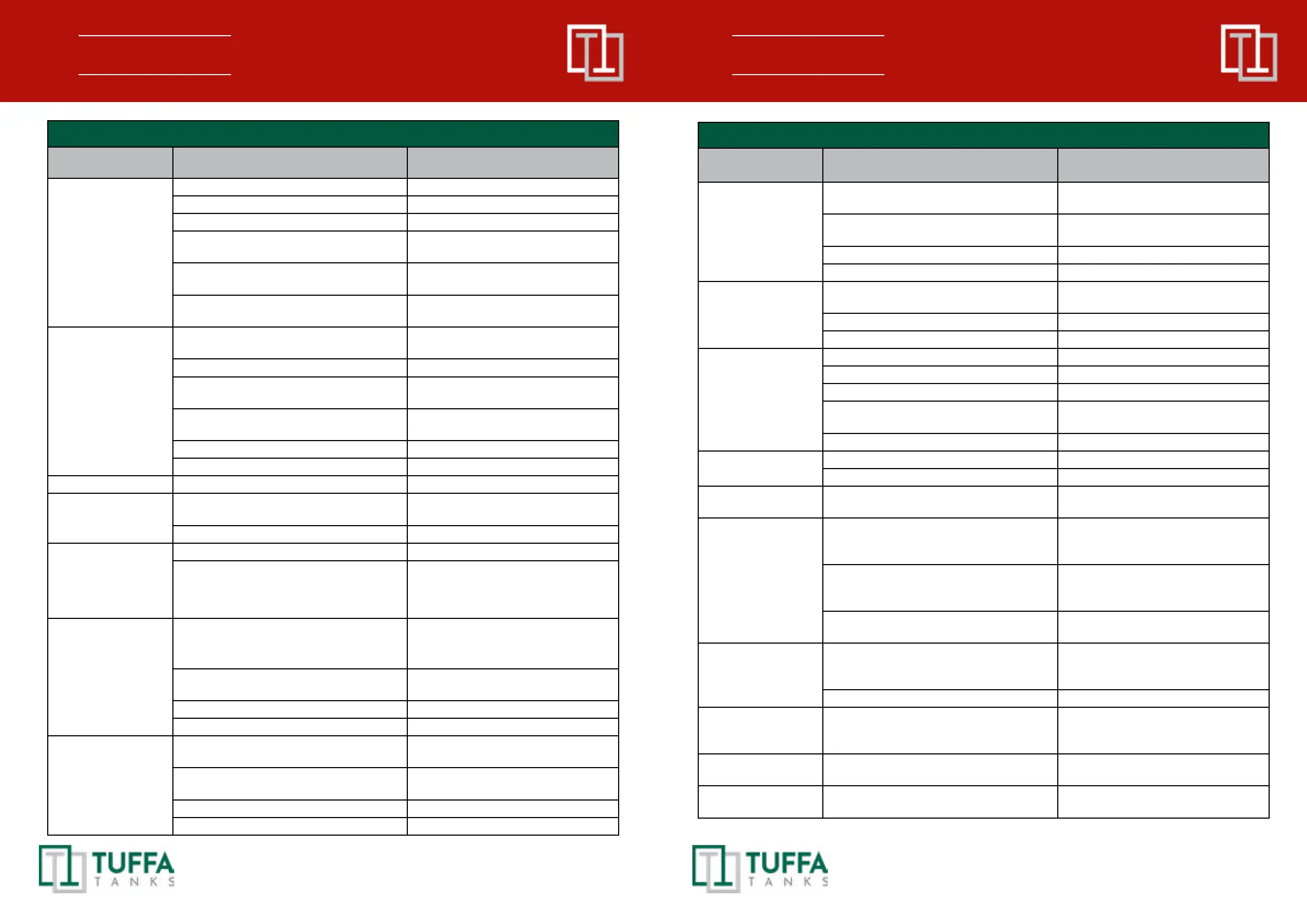

8.4 Troubleshooting

Symptom PossibleCauses Solutions

Bundalarmnot

working

1.Bundoatswitchnotpostioned

correctly

1.Alterpositionofoatswitchtohang

approximately1”obundoor

2.Bundoatnotabletomovefreely 2.Checkoatswitchforblockageor

replaceifnecessary

3.Damagetobundcable 3.Refertomanufacturer

4.Floatswitchcable 4.Refertomanufacturer

Dieselinbundcavity 1.Innertankoverll 1.Dieselmustberemovedfromthe

cavityassoonaspossible

2.Pipeworkleakinginbundcavity 2. See point 1

3.Innertankleaking 3. See point 1

Pipeworkleaking 1.Threadedconnectionloose 1.Connectionmustbetightened

2.Threadsealantdegraded 2.Threadsealantmustbereplaced

3.O-ringorsealjointperished 3.O-ringorsealmustbereplaced

4.Swagedhoseendsleaking 4.Hoseassemblyneedsreplacing:

refertomanufacturer

5.Rubberhoseperished 5. See point 4

Hosereelnot

operatingcorrectly

1.Internalreelspringhascomeloose 1.Refertomanufacturer

2.Springfailure 2.Refertopoint1

Leakfromtheshaft

gasket

1.Damagedgasket 1.Remove(seesection“Gearunit”)

andreplacetheOringandthebush

Insucientaccuracy 1.Wrongcalibration 1.Repeatcalibrationfollowingthe

instructionsinsection“Measuring

chamber”

2.Soiledorblockedmeasuringchamber 2.Cleanthemeasuringchamber

followingtheinstructionsinsection

“Meterunit”

3.Airintheuid 3.Locateandeliminateleaksininlet

lines

Reducedowrate 1.Cloggedorblockedmeasuring

chamber

1.Cleanthemeasuringchamber

followingtheinstructionsinsection

“Measuringchamber”

2.Blockedorsoiledlter 2.Cleanthelter

Innertankhaslifted

upandrupturedbund

lid

1.Dieselinsidebundiscausinginnertank

tooat

1.Refertomanufacturer

Tankexterior

damaged

1.Impactfromexternalforce 1.Ifthedamageissignicantreferto

manufacturerforfurtherinformation

Flipliddoesnotopen

easily

1.Gasstrut(s)havede-gasedandarenot

operating

1.Gasstrut(s)needreplacing

Loading...

Loading...