14 15

6. Installation & commissioning

6.1 Installation guidelines

TheproprietoroftheTuaFuelStationisresponsibleforcomplyingwithalllegal

requirementsrelatingtotheinstallationanduseofthisproduct,aswellastheguidelines

issuedbylocalreghtingauthoritiesandenvironmentalauthorities.

OncetheTuaFuelStationhasbeenreceivedonsite,checkthatnodamagehasoccurred

whileintransit.Locatethetankinthedesiredlocationusingeitheracrane,forkliftorrollers.

6.2 System installation

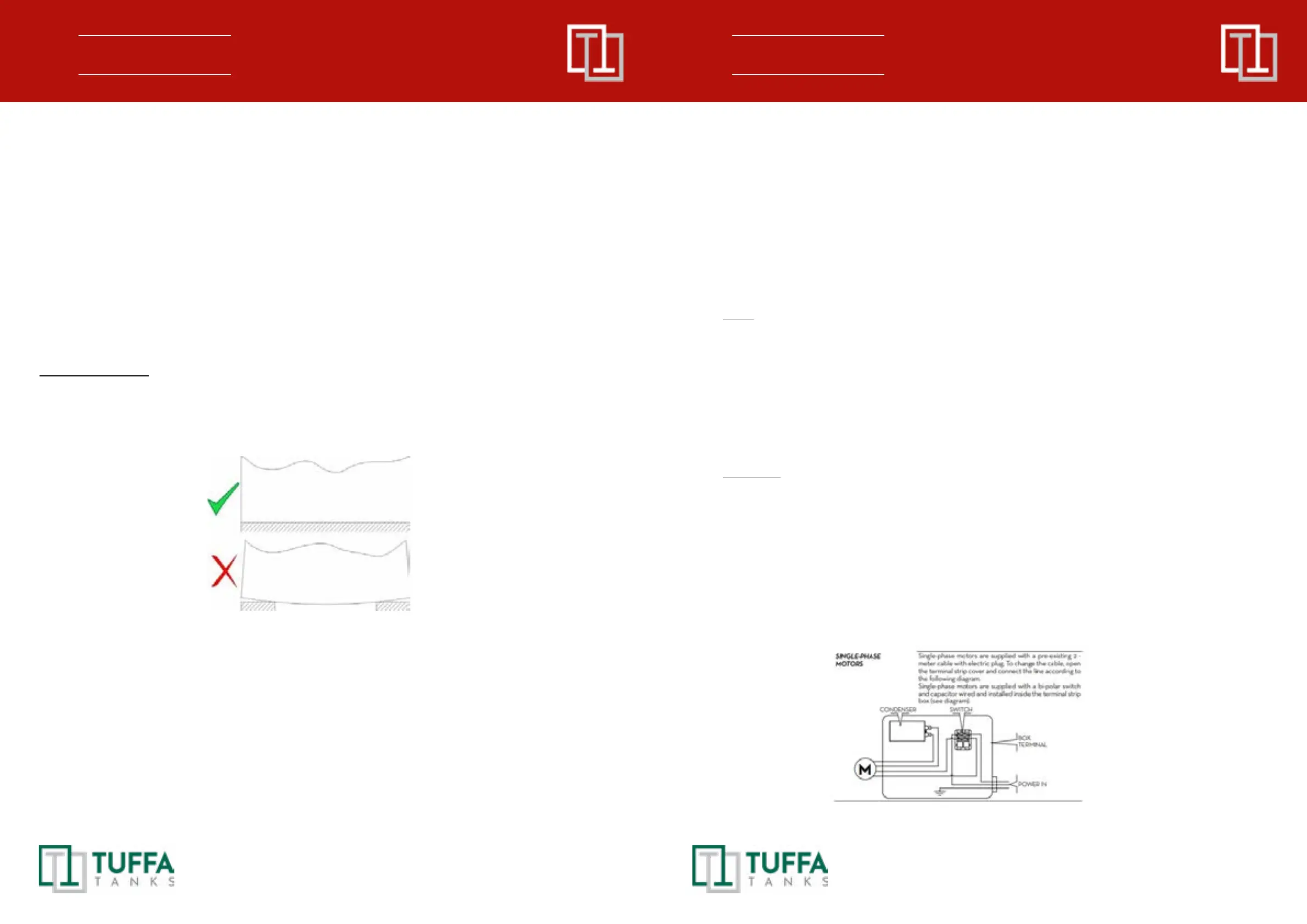

Systemfoundation

Thesystemmustbeinstalledandfullysupportedonasmoothlevelledconcretebasebuiltin

accordancewithgoodbuildingstandardsandengineeringprinciples.Itisrecommendedthat

tanksbeinstalledonaconcretebaseatleast100mmthick.Pleaserefertodiagrambelow:

6.3 System location

Thelocationofthesystemshouldbepositionedbyaroadorpassingwithsucientwidth,

andloadingcapacitytoaccommodateatankerdeliveringdiesel.ProvisionfortheU-turnof

atankershouldbeconsidered.Potentialobstaclesintheformoftreebranches,highvoltage

lines,orparkedvehiclesmustbeminimized.

Thespacearoundthesystemshouldallowfreeandcollision-freemovementofserved

vehicles.

Provisionshouldbemadetoprotecttankfromimpactdamage.

6. INSTALLATION & COMMISSIONING

6.4 Electrical requirements

Onlyasuitablyqualiedelectricianaccordingtoapplicableregulationsmayworkonthe

electricwiringinstallation.Thesystemcomponentsunderservice,maintenance,andrepair

workmustbedisconnectedfromthepowersupplybeforeanyworkinundertaken.

System power requirements:

230V

• 220-240Volts,50Hz+/-10%

• 20ampcircuitbreakerrecommended

• Powercablerecommendation:3Core2.5mmexcable

• Dutycycle:20minutes

• CAUTION: DO NOT RUN PUMP MOTOR WITH A CLOSED NOZZLE FOR MORE

THAN 2 MINUTES

12V/24V

• Cableclipscomepre-wired

• Dutycycle:20minutes

• CAUTION: DO NOT RUN PUMP MOTOR WITH A CLOSED NOZZLE FOR MORE

THAN 2 MINUTES

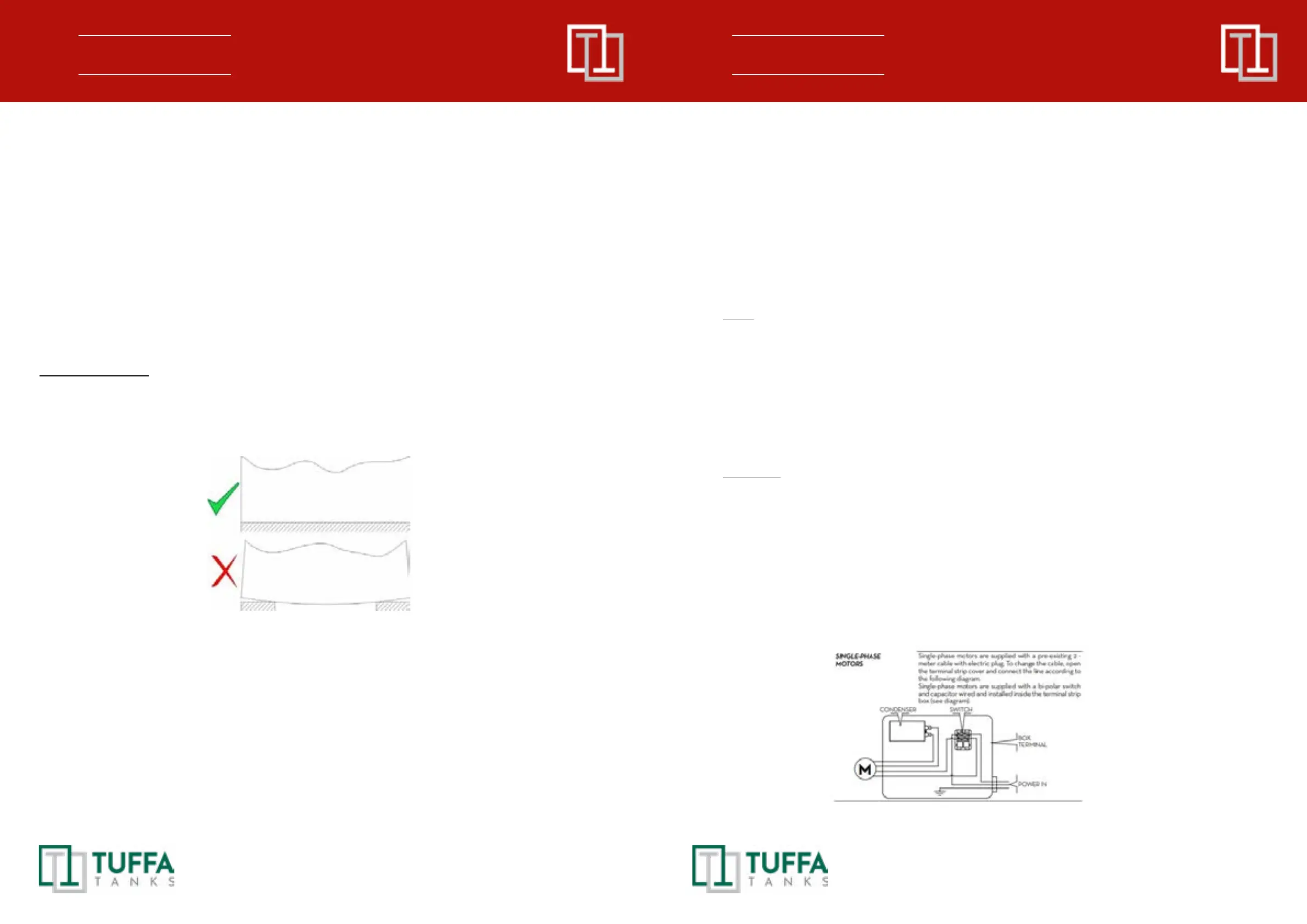

6.5 Electrical wiring diagram (230 V)

6.5.11350SLBFS/2500HBFS–KeySwitch

6. INSTALLATION & COMMISSIONING

Loading...

Loading...