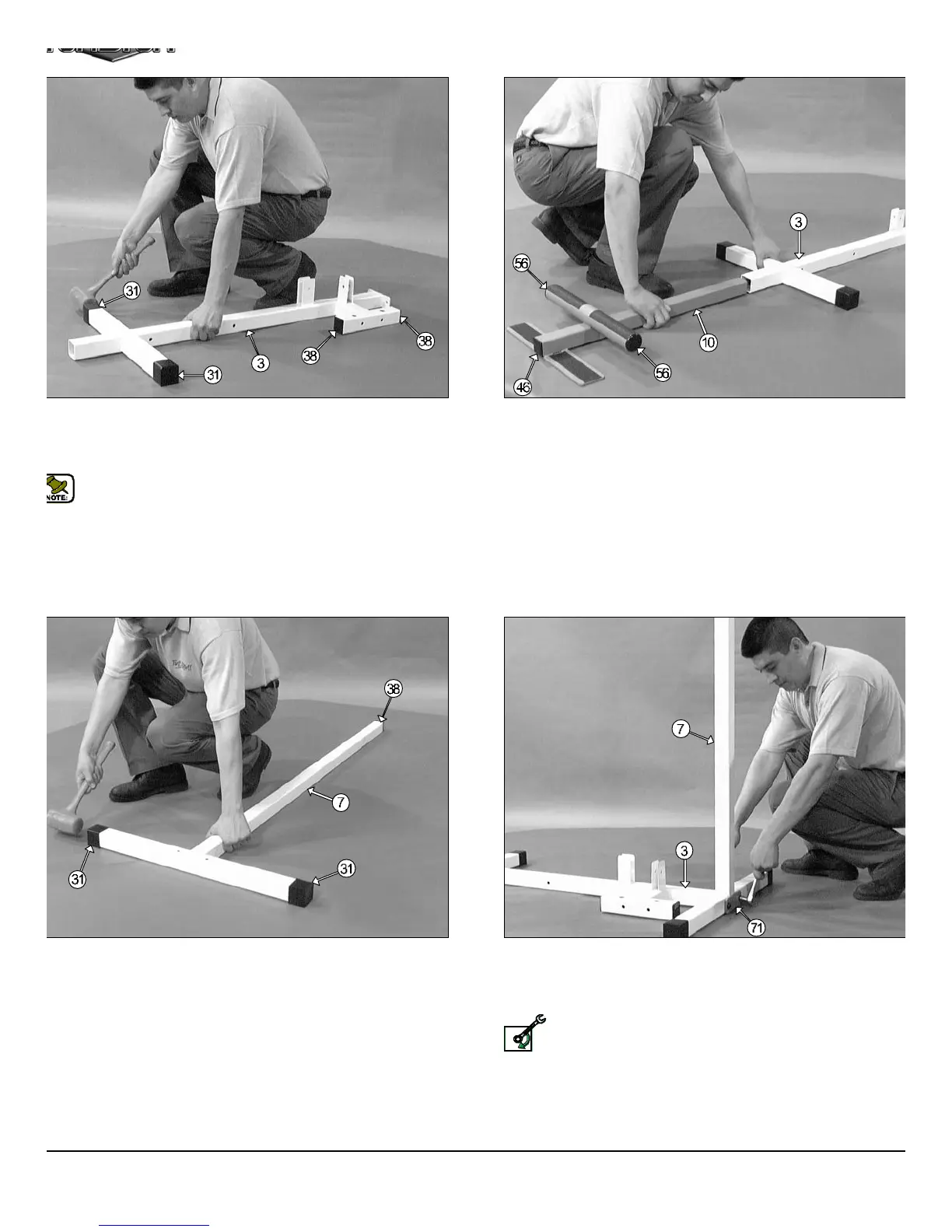

IG. 3 On a flat surface, lay the Base Frame (#3) down and insert two

lastic Insert Caps 2” Sq. (#38) into the Base Frame (#3). Next, insert

o Plastic End Caps w/Groove 2” Sq. (#31) onto the front stabilizer of the

ase Frame (#3), as shown above.

Note: When positioning the Base Frame (#3) consider the

complete area surface of the CFM-500. Use the overhead view on

the cover page for designing your layout before assembling.

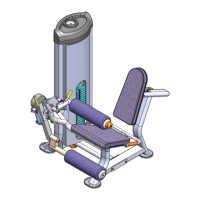

FIG. 4 Next, locate the Low Row Foot Assembly (#10) and, using

rubber mallet, insert two Plastic End Caps 2” Rd. (#56) and one Plast

Insert Cap 1 3/4 Sq. (#46) into the tube-ends, as shown above. Ne

slide the Low Row Foot Assembly (#10) into the receptacle of the Ba

Frame (#3), as shown above.

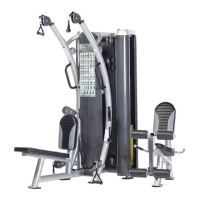

IG. 5 Next, locate the Rear Upright (#7) and, using a rubber mallet,

set one Plastic Insert Cap 2" Sq. (#38) into the tube-end. Next, insert

o Plastic End Caps w/Groove 2" Sq. (#31) onto the rear stabilizer of the

ear Upright (#7), as shown above.

3

CFM-500 Compact Frontal Machin

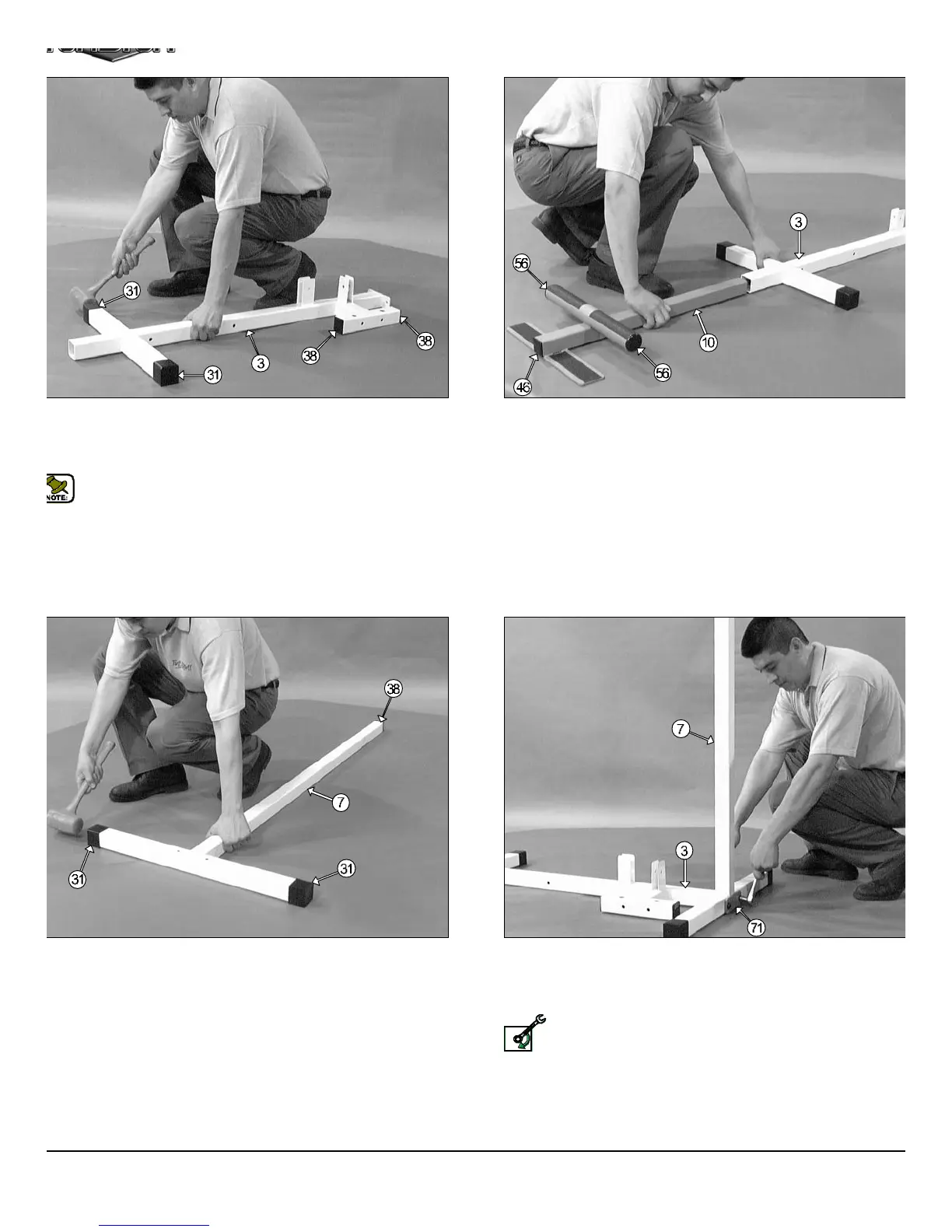

FIG. 6 Attach the Rear Upright (#7) and a Support Plate 1/4 X 2 X

(#71) to the Base Frame (#3) and secure them into place using two H

Head Cap Screws 3/8-16 X 3 1/4 (#49), four Flat Washers SAE 3/8” (#4

and two Nylon Insert Lock Nuts 3/8-16 (#51).

Loosely Fasten: Do not completely fasten this hardwa

assembly at this time, as it will be completely fastened later in t

assembly process.

LOOSELY FASTEN

Loading...

Loading...