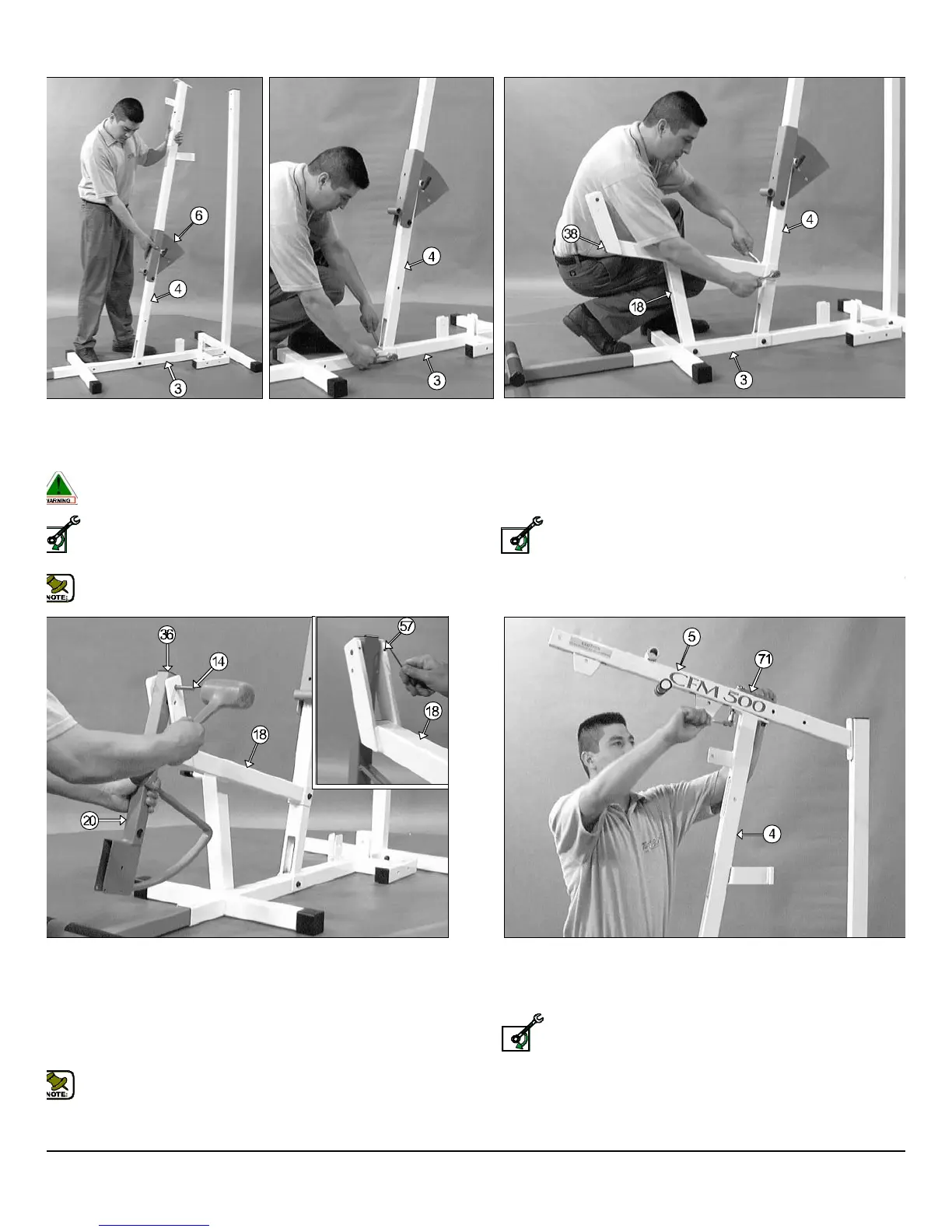

FIG. 10 Attach the Top Pulley Housing (#5) to the Front Uprig

(#4) and secure it into place using one Support Plate 1/4 X 2 X 5 (#71

two Hex Head Cap Screws 3/8-16 X 3 1/4 (#49), four Flat Washers SA

3/8 (#45) and two Nylon Insert Lock Nuts 3/8-16 (#51).

Loosely Fasten: Do not completely fasten this hardwa

assembly at this time, as it will be completely fastened later in t

assembly process.

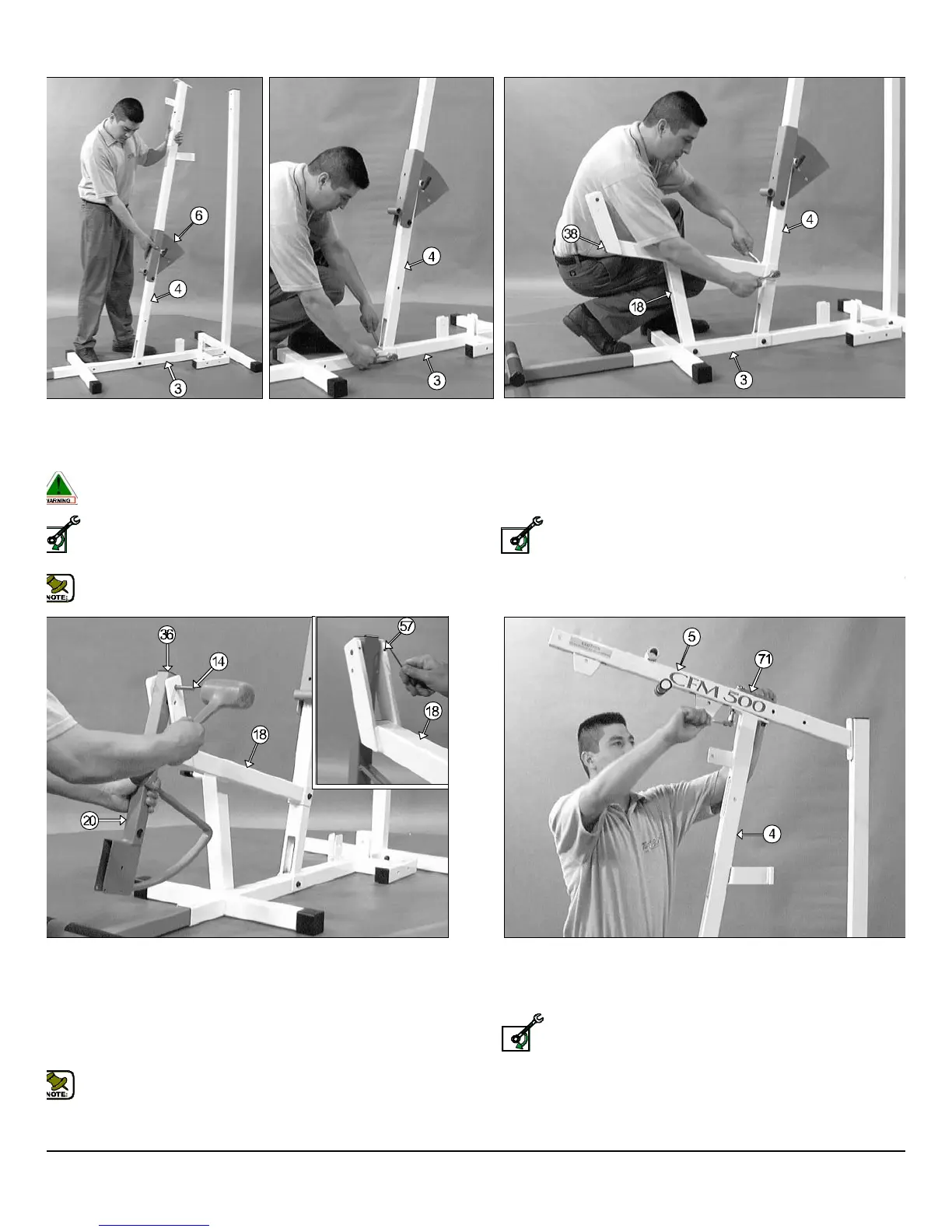

IG. 7 Attach the Front Upright (#4) to the Base Frame (#3) and

cure it into place using one Hex Head Cap Screw 3/3-16 X 2 3/4 (#47),

o Flat Washers SAE 3/8 (#45) and one Nylon Insert Jam Lock Nut 3/8-

(#48).

Warning: This procedure requires the assistance of another per-

son.

Loosely Fasten: Do not completely fasten this hardware

assembly at this time, as it will be completely fastened later in the

assembly process.

Note: The Back Pad Bracket (#6) has been pre-assembled to the

Front Upright (#4) by the factory.

FIG. 8 Attach the Leg Extension Bench Frame (#18) to the Bas

Frame (#3) and secure it into place using one Hex Head Cap Screw 3/

16 X 4 1/2 (#53), two Flat Washers SAE (#45) and one Nylon Insert Ja

Lock Nut 3/8-16 (#48). Next, attach the Leg Extension Bench Fram

(#18) to the Front Upright (#4) and secure it into place using one He

Head Cap Screw 3/8-16 X 2 3/4 (#47), two Flat Washers SAE 3/8 (4

and one Nylon Insert Jam Lock Nut 3/8-16 (#48).

Loosely Fasten: Do not completely fasten this hardwa

assembly at this time, as it will be completely fastened later in th

assembly process.

Next, insert one Plastic Insert Cap 2” Sq. (#38) into the front of the Le

Extension Bench Frame (#18).

IG. 9 Affix the Leg Extension Arm (#20), in the position as shown, to

e Leg Extension Bench Frame (#18) and secure it into place using the

eg Extension Axle 1/2 X 2 1/2 (#14). Next, secure the Leg Extension

xle 1/2 X 2 1/2 (#14) into place using two Set Screws 1/4-20 X 3/8 (#57),

shown in caption above. Use the supplied Hex Key 1/8 (#77) for

stening these Set Screws 1/4-20 X 3/8 (#57). Next, insert one Plastic

sert Cap 1 1/2 Sq. (#36) into the tube-end of the Leg Extension Arm

20).

Note: It is recommended to grease the Leg Extension Axle 1/2 X

2 1/2 (#14) with multi-purpose grease prior to assembling.

FM-500 Compact Frontal Machine

4

wner

s

anua

:

ssem

y

ns

ruc

on

SELY FASTEN

LOOSELY FASTEN

LOOSELY FASTEN

Loading...

Loading...