Service Manual 73

Page 10 of 32

REMOVE THE COVER GASKET:

If a new gasket is not available, reuse of the original gasket is acceptable, provided it is not

torn or otherwise damaged.

REMOVE THE IDLER FROM THE PIN:

With the idler gear still on the cover, check for excessive wear between:

− the pin and bushing,

− the idler and cover crescent,

− idler width and crescent height.

Any visible signs of excessive wear will require replacement of the cover/pin assembly

and/or the idler and the bushing.

If only the bushing shows signs of minor wear, it should be replaced. Acceptable bushing

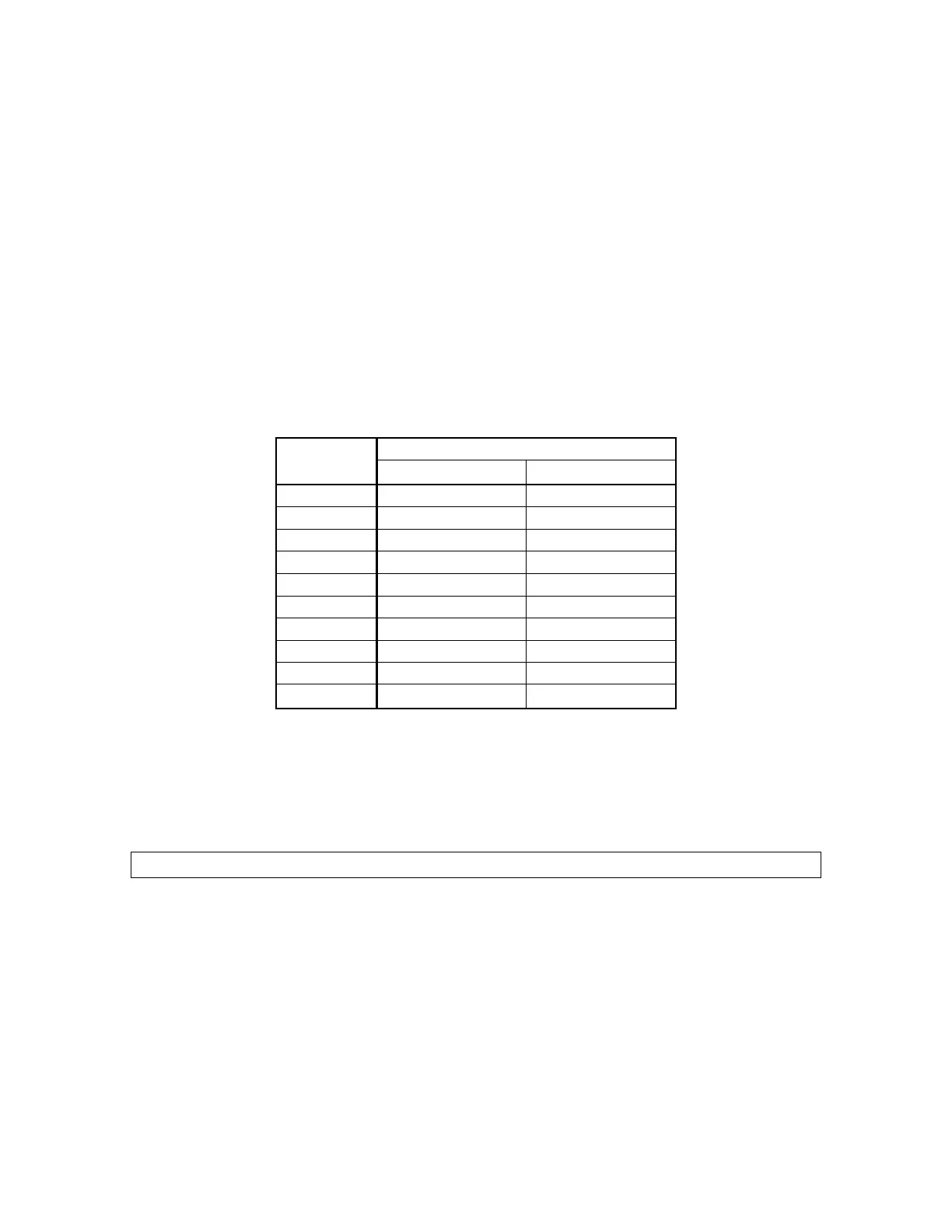

clearances are shown in Table 3 (for pumps with standard clearance only)

Acceptable Clearance

Pump Size

inch mm

GG015 0.001 -0.007 0.038 -0.178

GG030 0.001 -0.007 0.038 -0.178

GG050 0.002 -0.008 0.051 -0.203

GG070 0.002 -0.008 0.051 -0.203

GG080 0.002 -0.008 0.051 -0.203

GG090 0.002 -0.008 0.051 -0.203

GG120 0.002 -0.009 0.064 -0.229

GG130 0.002 -0.009 0.064 -0.229

GG200 0.003 -0.009 0.089 -0.229

GG210 0.003 -0.009 0.089 -0.229

Table 3 - Idler Bushing Clearances

Note: Many Tuthill pumps are provided with non-standard clearances for use with high-

viscosity or high-temperature fluids. Consult the factory for clearances of these pumps.

Drive Module Removal

REMOVE THE DRIVE MODULE ASSEMBLY FROM HOUSING:

If service is being completed with the housing still mounted to the baseplate/piping, you must first

remove the spacer from the spacer coupling.

Adequately support the housing ( on the cover side) so it will not fall.

Remove the bolts that hold the bracket to the housing.

On pumps that do not have a cast integral foot, remove the bolts that attach the foot to the

bearing carrier.

Loading...

Loading...