33

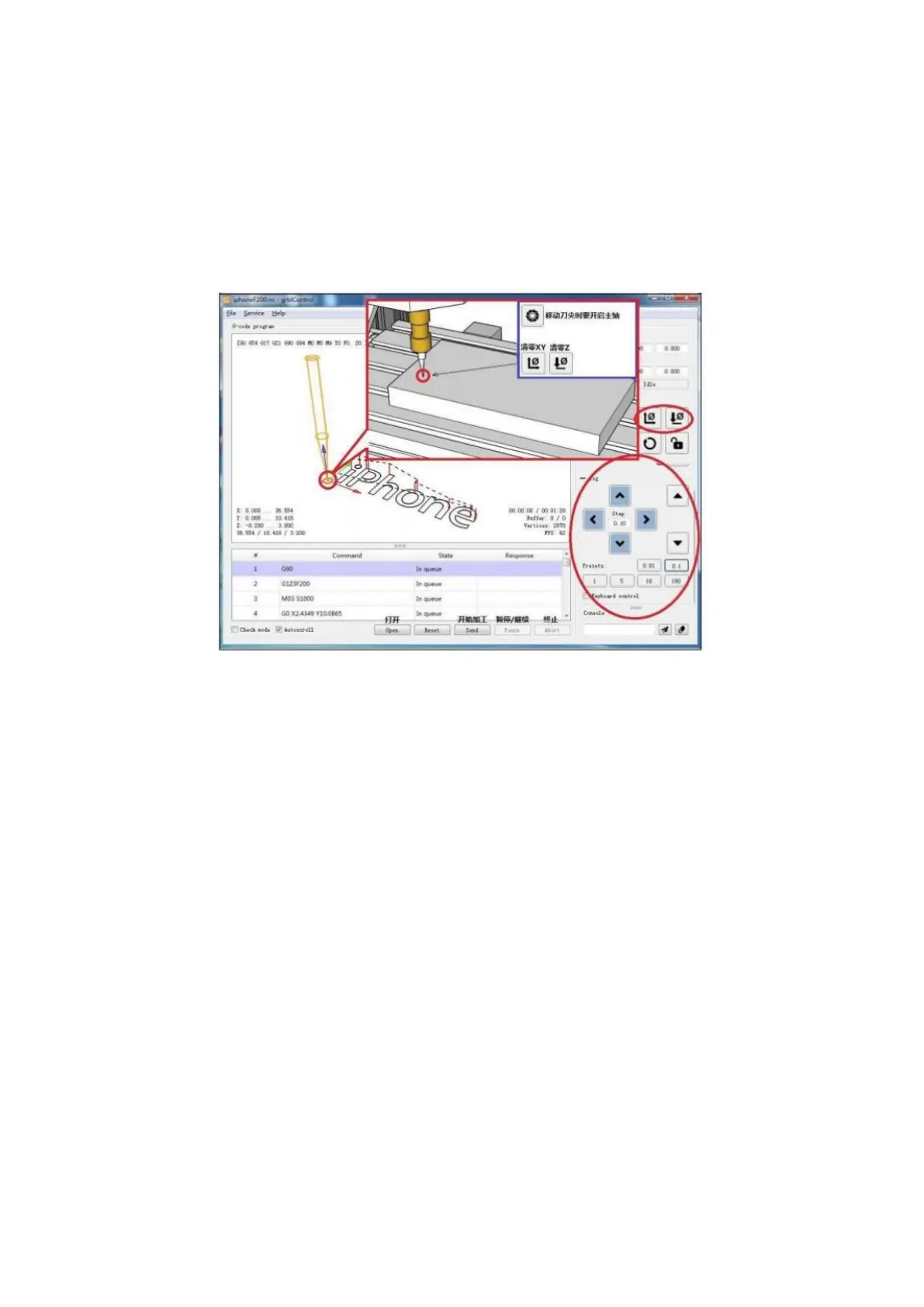

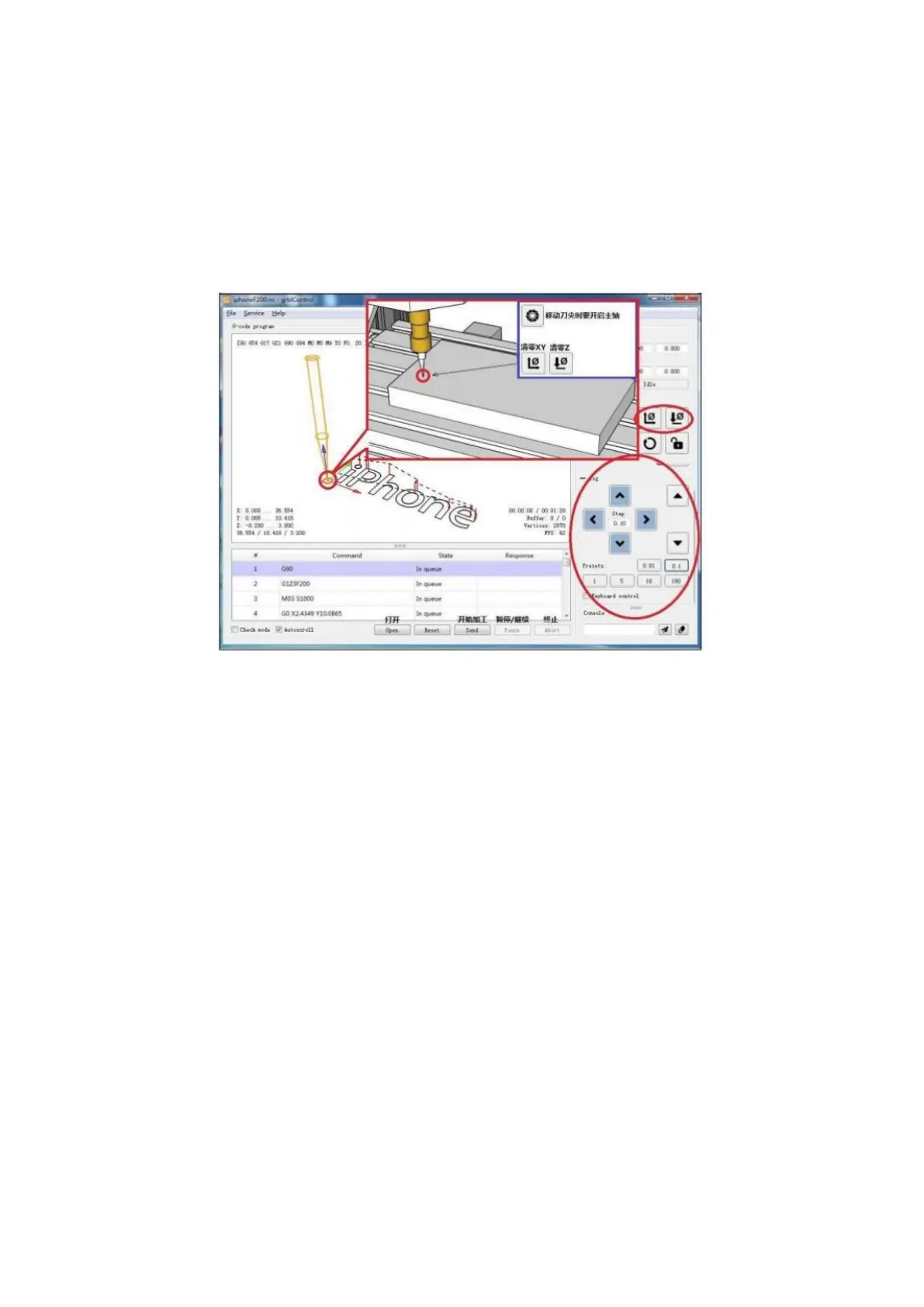

Cutter Configuration:

Cutter Configuration: Establish the starting position for the task. Position the cutter at

the desired location, proceed to click on XY and Z axis coordinate zero clearing. This

action will initiate the engraving process from the designated point. While performing

the final step, ensure that the spindle is in operation, as the cutter might come into

contact with the object intended for engraving.

Once you've successfully conducted your initial tests, you'll find yourself ready to delve

into crafting your very own Gcode for engraving purposes. Gcode serves as the set of

commands responsible for orchestrating the machine's movements to create intricate

designs. These commands are encapsulated within a .nc file format. To get you started,

take a look within the provided folder – you'll discover a collection of .nc files that can

serve as references.

For generating these .nc files, a software that you can consider is ARTCAM. Although the

linked version is an older one, it can still provide the foundation you need. If you're

interested in acquiring the latest iteration of ARTCAM, a quick online search should point

you in the right direction. This software holds a ubiquitous presence and is renowned

for its capabilities. (https://www.dropbox.com/s/n1pi86z2lu5zd8q/ArtCAM.rar?dl=0)

Should you wish to deepen your familiarity with the process of generating .nc files using

ARTCAM, there's an abundance of learning resources available on YouTube.

(https://www.youtube.com/user/delcamartcam/videos) By navigating to the channel

"delcamartcam," you'll encounter a wealth of tutorial videos that comprehensively guide

you through the process. This visual aid can empower you with the insights needed to

harness ARTCAM's potential and craft Gcode that brings your creative visions to life.

Loading...

Loading...