Z+

Z-

X-

EN

Set up TTC450 Pro

10

Operation Guide

11

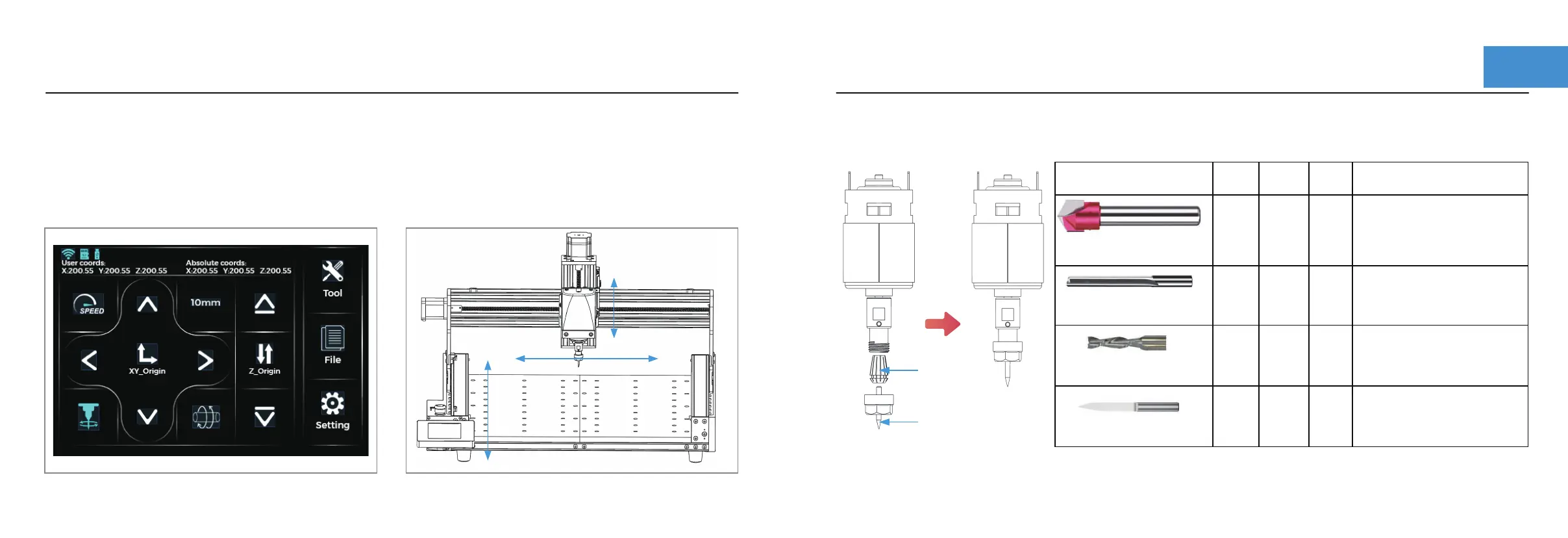

Note: The clamping length of the cutter is approximately 1/2 or 1/3 of the total length of the cutter.

Step 1 :Installation of milling cutter

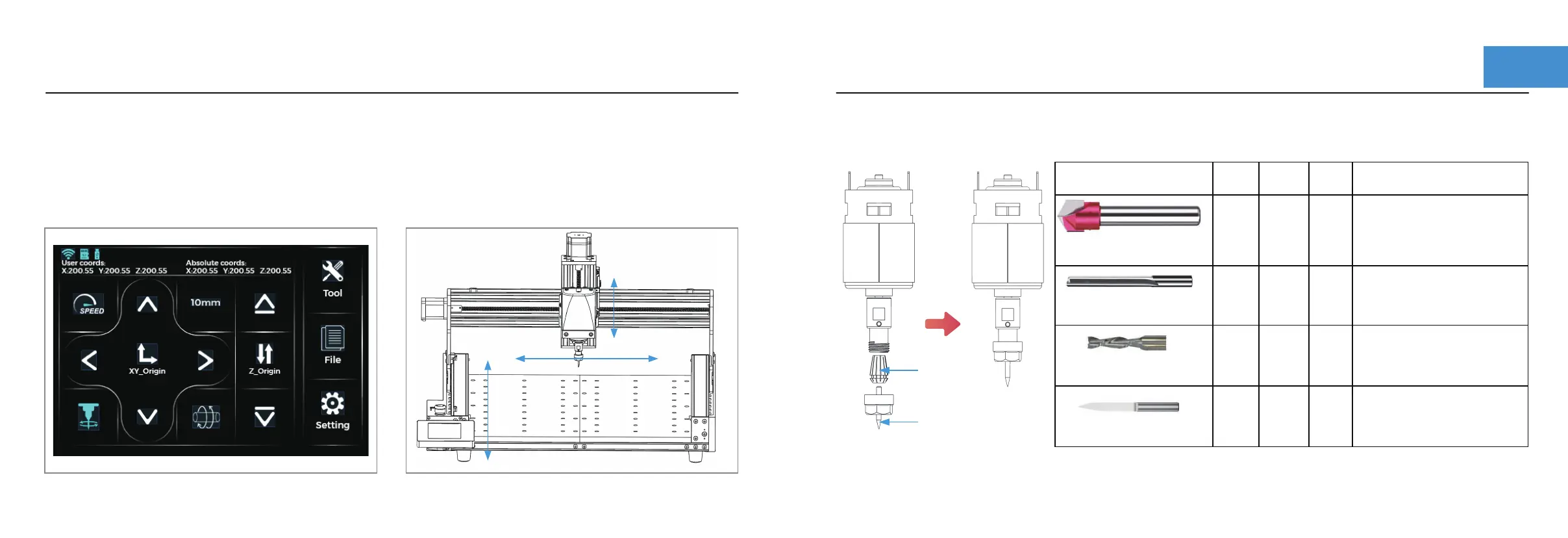

Click the "Control" button and move XY-axis to the bottom left corner of the machine.

Click XY Clear and Z Clear .Then move the XY axis away from the corner.

Click "NEXT", click "Home" to return to corner.XYZ axis will return to the bottom left corner of the machine.

Click "Spindle" to rotate the spindle. Click "Spindle" again to stop the spindle.

Make sure the emergency stop switch is popped up, plug in the power.If the screen lights up, the power on is

normal. If the screen does not light up, after power off, exchange the screen line position to reboot.

Step 6 :Test

Y+

Y-

X- X+

Z+

Z-

Y+

Y-

X+

V-Bit 0.393 Inch(10mm)

90 degree

Cutting

length

Flute

count

Ovreall

length

Explanatory note.

V-Bit tools are generally used

for engraving V-style letters.

They could also be used to

remove the background and

leave areas flat on the fac of

the material.

Straight cut

0.125 Inch(3.175mm)

Straight cut can be used for

Roughing, Area Clearance,

Cutouts, Inlays and Profiling.

30 degree carving cutter 0.125 Inch

(3.175MM diameter,0.1 end)

Millcutter

0.125 Inch(3.175mm)

11mm

20mm

50mm

2

2

2

1

38mm

39mm12mm

15mm

27mm

Use for fine detail engraving.

Designed for routing where

upward chip removal, tool

rigidity, long life and high

quality finish is desired.

CNC tool

ER11 chuck

Loading...

Loading...