Always check the reason for a blown fuse otherwise the new fuse is also likely to blow.

NEVER EVER USE WIRE in place of correct grade fuse.

CHECKING THE WIRING HARNESS AND FUSES

Loose wires make inferior connections and damaged wires can cause short circuits, fires burnt wiring or reduce efficiency of

components. Replace or repair any faulty wiring or insulation.

If a fuse burns out again after it has been replaced, do not replace it with wire or a high capacity fuse, find the cause and rectify it

or get an auto electrician to do so.

Where insulation is chafed or peeled off, recover the area with a good quality insulation tape.

Where wiring comes out of it’s fitting replace it correctly with the standard fitting.

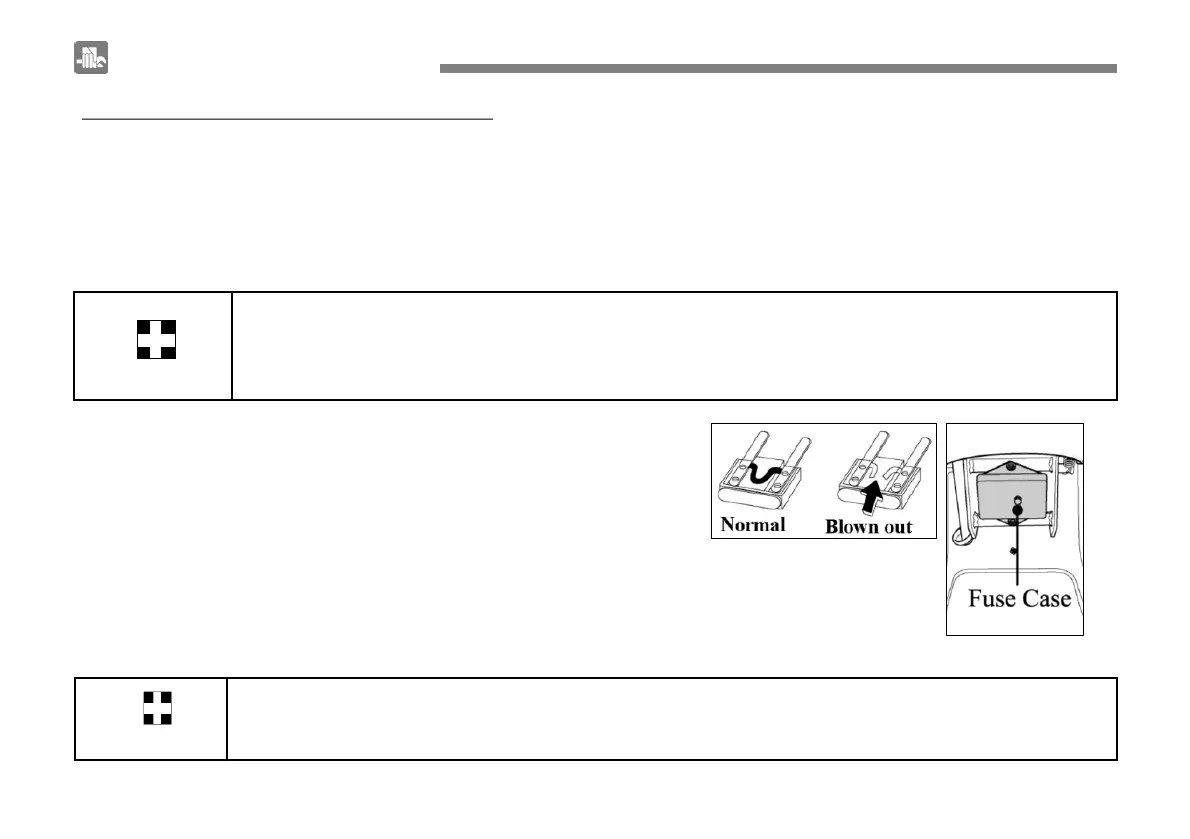

■ REPLACING FUSES

The circuit has blade type fuses in its wiring circuit.

When a fuse has blown replace it with one of the same value.

Using a large capacity fuse or wire burn out the wiring system.

Use fuse tongs to replace fuses.

IMPORTANT

Incorrect wiring or fuses can cause fires to both the tractor and surrounding area so get the dealer to check it

annually.

Likewise fuel pipes and wiring age with use.

Ask your dealer to check it at least once every 2 years and replace as required.

■ MAIN FUSES

The wiring harness is equipped with main fuses who’s function is to preserve the wiring.

However when a main fuse blows the entire circuit is dead.

Always check the reason & rectify before replacing the fuse of the same value.

To indicate that the fuse is blown it will be discolored.

IMPORTANT

MAINTENANCE AND SERVICE

5-16

Loading...

Loading...