|

29

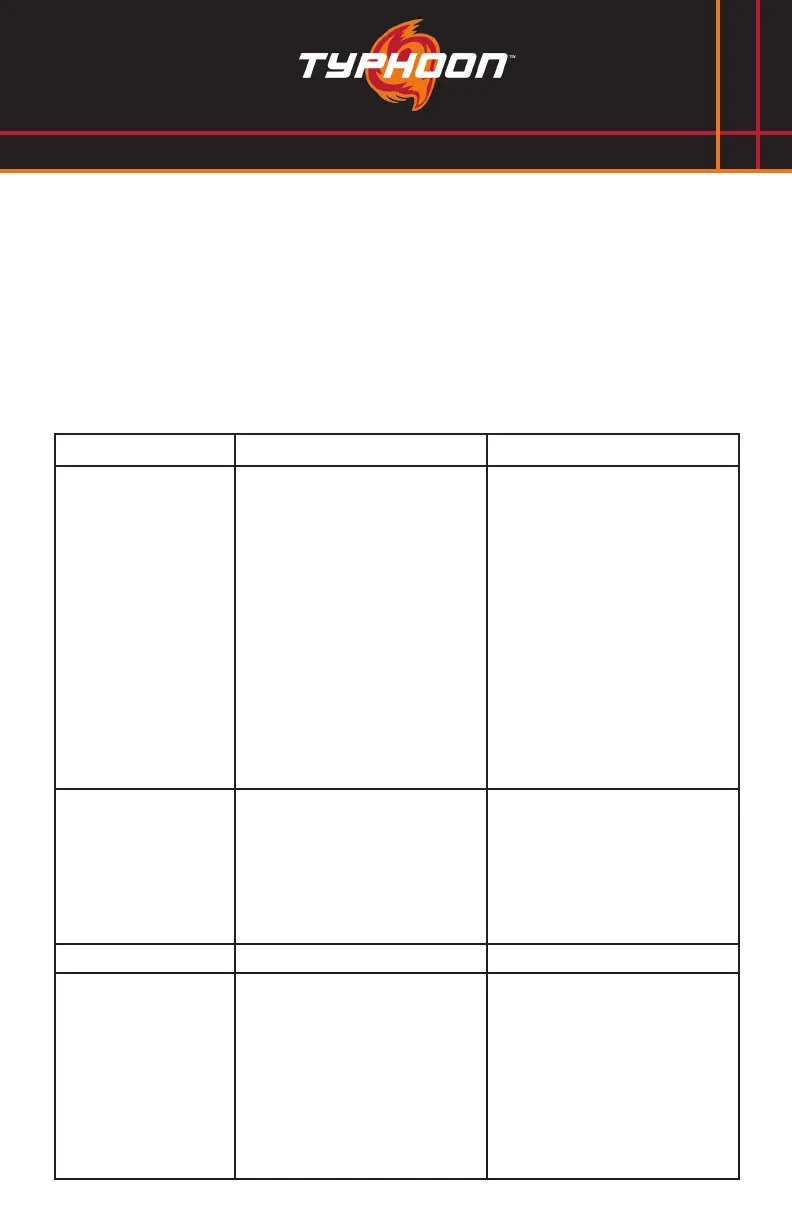

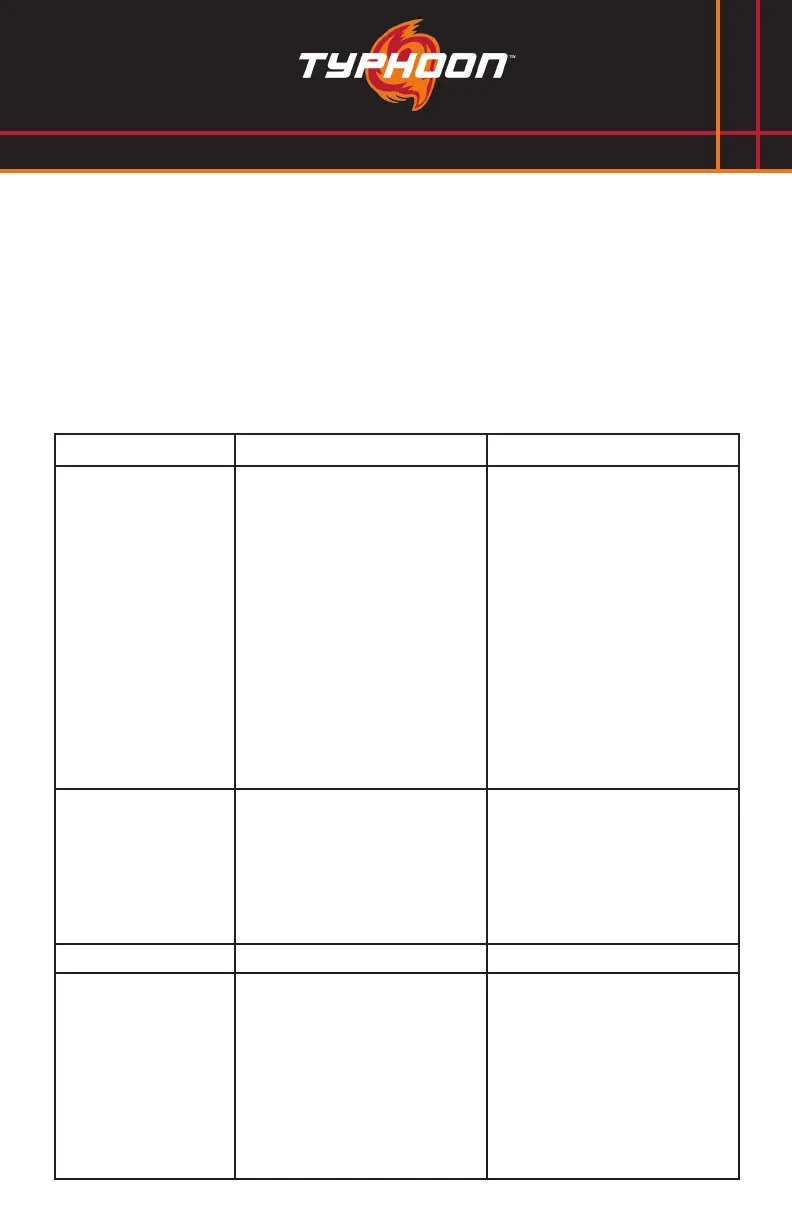

Troubleshooting Chart

If you are experiencing a problem that is not listed in this chart,

or have checked all the possible cause listed and you are still

experiencing the problem. Please Contact Customer Service at

1- 866-338-7519.

GASOLINE ENGINES

TROUBLESHOOTING

Problem Cause Correction

Unit has following

problems: failure to

produce pressure,

erratic pressure,

chattering, loss of

pressure, low water

volume.

Low pressure spray tip installed.

Water inlet is blocked.

Inadequate water supply.

Inlet hose is kinked or leaking.

Clogged inlet hose screen.

Water supply is over 100°F (38°C)

High pressure hose is blocked or

leaks.

Spray gun leaks.

Spray tip is obstructed.

Pump is faulty.

Replace with high pressure spray

tip.

Clear inlet.

Provide adequate water ow.

Straighten inlet hose, patch leak.

Check and clean inlet hose screen.

Provide cooler water supply.

Clear blocks in outlet hose.

Replace spray gun.

Clean spray tip.

Contact local service facility.

Detergent fails to mix

with spray.

Detergent siphoning tube is not

submerged.

Detergent siphoning tube/lter is

clogged or cracked.

High pressure spray tip installed.

Insert detergent siphoning tube into

detergent.

Clean or replace lter/detergent

siphoning tube.

Replace with low pressure spray

tip.

Engine lacks power. Dirty air lter. Replace air lter.

Engine will not start Throttle lever on/off switch in OFF

position

No fuel in engine

Worn fouled or dirty spark plug

Pressure build up in pump

Turn throttle lever to ON position

Fill fuel tank or turn on fuel supply

Replace with factory recommended

spark plug

Squeeze trigger on spray wand

(refer to operating instructions in

owner’s manual)

Loading...

Loading...