NEO-8Q / NEO-M8 - Hardware integration manual

UBX-15029985 - Production information Product handling Page 20 of 21

C1-Public

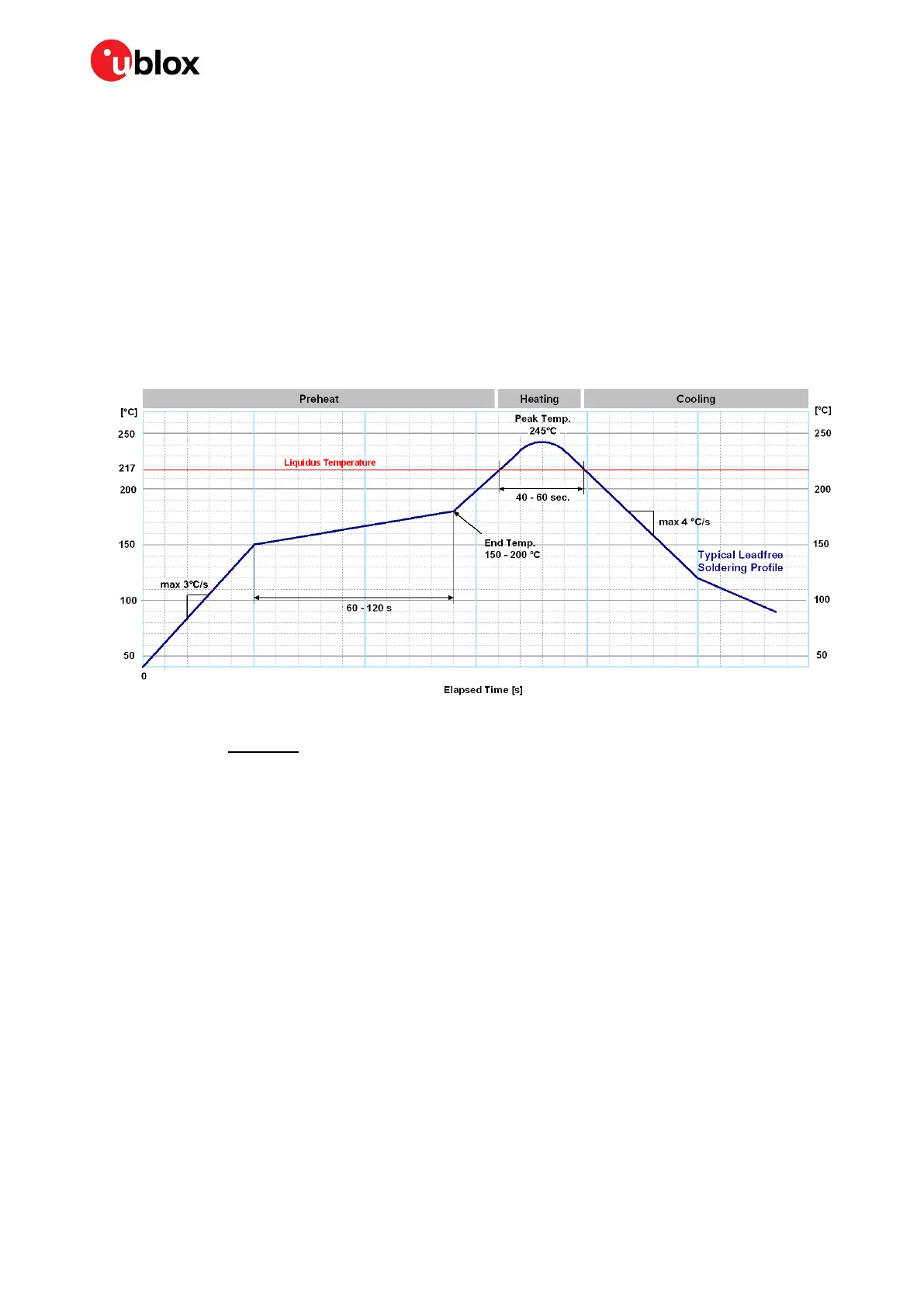

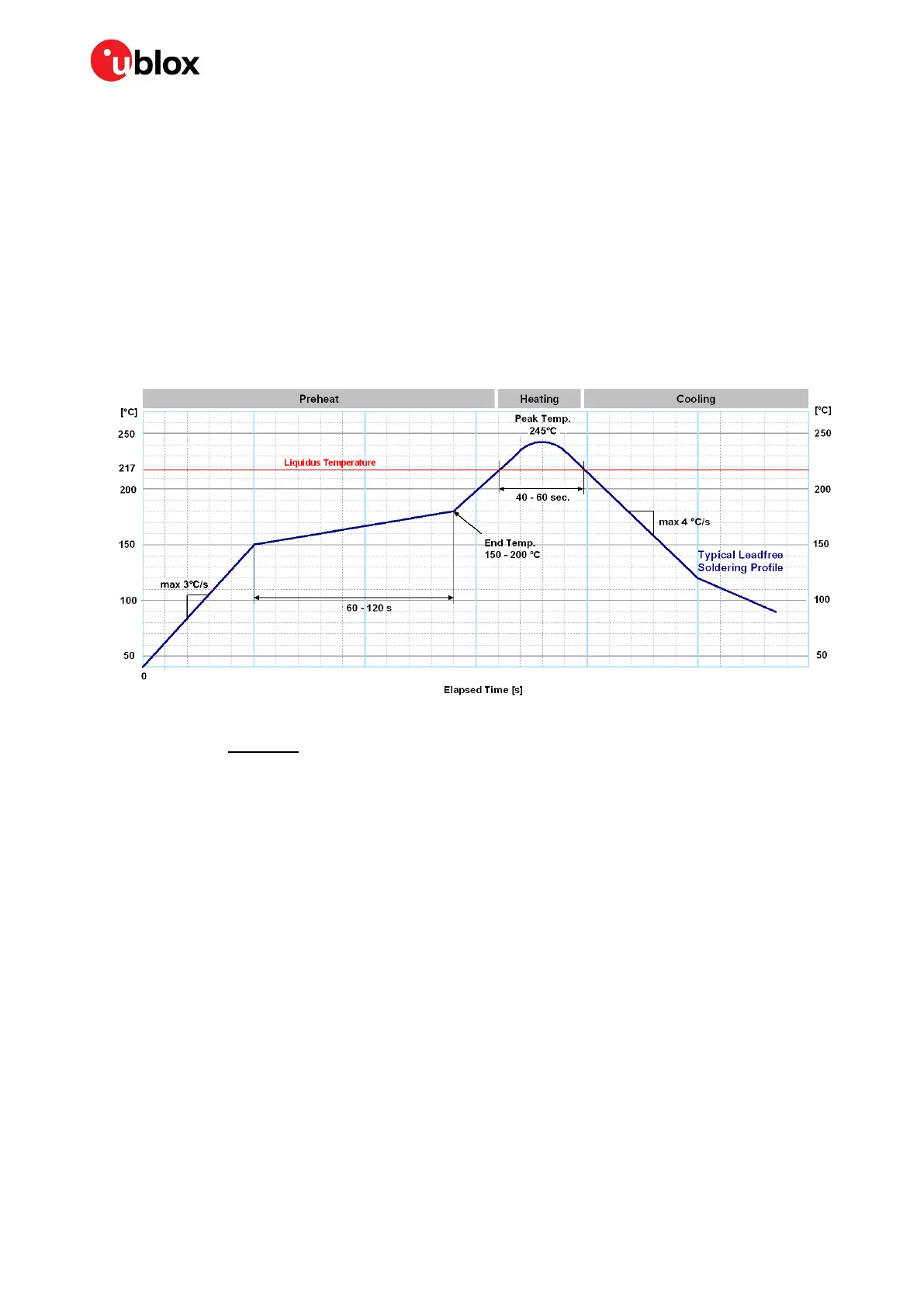

• Peak reflow temperature: 245 °C

Cooling phase

A controlled cooling avoids negative metallurgical effects of the solder (solder becomes more brittle)

and possible mechanical tensions in the products. Controlled cooling helps to achieve bright solder

fillets with a good shape and low contact angle.

• Temperature fall rate: max 4 °C/s

☞ To avoid falling off, place the u-blox module on the topside of the motherboard during soldering.

The final soldering temperature chosen at the factory depends on additional external factors like

choice of soldering paste, size, thickness and properties of the base board. Exceeding the maximum

soldering temperature in the recommended soldering profile may permanently damage the module.

Figure 11: Recommended soldering profile

☞ u-blox modules must not be soldered with a damp heat process.

Optical inspection

After soldering the u-blox module, consider an optical inspection step to check whether:

• The module is properly aligned and centered over the pads

• All pads are properly soldered

• No excess solder has created contacts to neighboring pads, or possibly to pad stacks and vias

nearby

Cleaning

In general, cleaning the populated modules is strongly discouraged. Residues underneath the

modules cannot be easily removed with a washing process.

• Cleaning with water will lead to capillary effects where water is absorbed into the gap between the

baseboard and the module. The combination of residues of soldering flux and encapsulated water

leads to short circuits or resistor-like interconnections between neighboring pads.

• Cleaning with alcohol or other organic solvents can result in soldering flux residues flooding into

the two housings, areas that are not accessible for post-wash inspections. The solvent will also

damage the sticker and the ink-jet printed text.

• Ultrasonic cleaning will permanently damage the module, in particular the quartz oscillators.

The best approach is to use a “no clean” soldering paste and eliminate the cleaning step after the

soldering.

Loading...

Loading...