Construcción

ConstrucciónConstrucción

Construcción

9

MK

MK MK

MK STRUCTURE

STRUCTURESTRUCTURE

STRUCTURE

1.2.2. PARAPET FORM CARRIER

PARAPET FORM CARRIERPARAPET FORM CARRIER

PARAPET FORM CARRIER

This form carrier is a lighter version of the previous one. It is used for applications with lower load-bearing and

forward-moving capacities. Unlike the one mentioned beforehand, the parapet form carrier can be moved manually

and requires a solid base where the guide rail rests on. The jacks of this form carrier type are able to withstand a

maximum load of approximately 150 kN.

The most common applications for parapet form carriers are the construction of protection parapets for bridges or

solutions that do not require high load-bearing capacity, mainly projects with formwork tables.

Form carrier for bridge parapets

Form carrier for bridge parapetsForm carrier for bridge parapets

Form carrier for bridge parapets

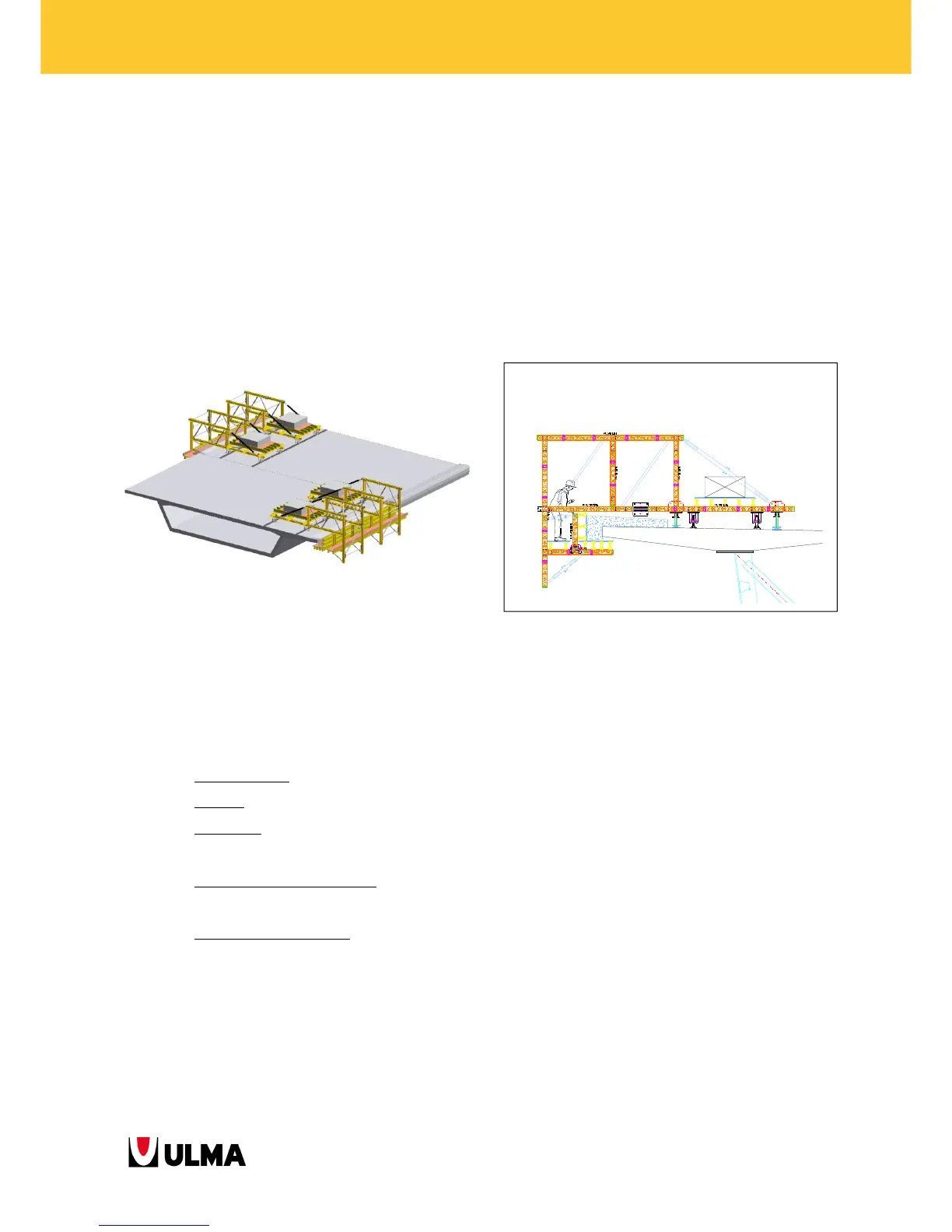

A parapet form carrier usually consists of the following parts:

o Main structure: structure bearing the concrete load.

o Bracing: components that withstand wind effects and transverse movements.

o Formwork: part in touch with the concrete shaping it, allowing its adjustment and opening if this is

required for the movement of the structure.

o Rolling and levelling system: components that enable the rolling of the truss and its levelling at a

specific place, as well as its stripping.

o Safety items and access: walkway platforms, handrails etc., depending on the requirements of each

project.

Loading...

Loading...