Storage

10 221.100.002-00 03/2021

www.uni-geraete.com

1. Attach protective caps to the sides of the valve.

2. Secure the device with lifting tackle. When doing so, only attach the lifting tackle to the housing. If possible,

transport the valve in a box or on a pallet with a soft underlay.

3. Place valve on level ground.

9 Storage

Store the valve and spare parts under the following conditions:

• Ambient temperature from -20 to +60 °C

• Max. humidity 40%

• Clean storage location

• Protect against sunlight

10 Installation

10.1 Notes on installation

Risk of crushing due to moving actuators!

Reaching into the device can lead to fatal injury from crushed and severed limbs.

• If the access point to the pipe system is less than 850 mm away from the valve or if the pipe is more than

500 mm in diameter, a safety guard must be installed.

• Protect the valve from the effects of weather, e.g. moisture.

• Before installation, compare the following valve specifications with the system diagram of the piping sys-

tem:

•Material

• Pressure

• Temperature

• Voltage

• Direction of flow

• Only connect and operate the valve when it is correctly installed.

See the nameplate for the valve’s installation position.

The valve must not be used as a fixed point. The valve is supported by the piping system.

For automatic shut-off valves: Install a strainer upstream of the valve. Observe the direction of flow

( in Fig. 1 – Fig. 7). The screen of the strainer must have the following characteristics:

• Clear mesh size ≤1.5 mm

• A test mandrel of Ø1 mm must not be able to pass through it.

When two valves are assembled in combination, one strainer is sufficient upstream of the first valve. UNI-

Geräte strainers of the SFR series in combination with solenoid valves are approved for use according to

EU/2016/426.

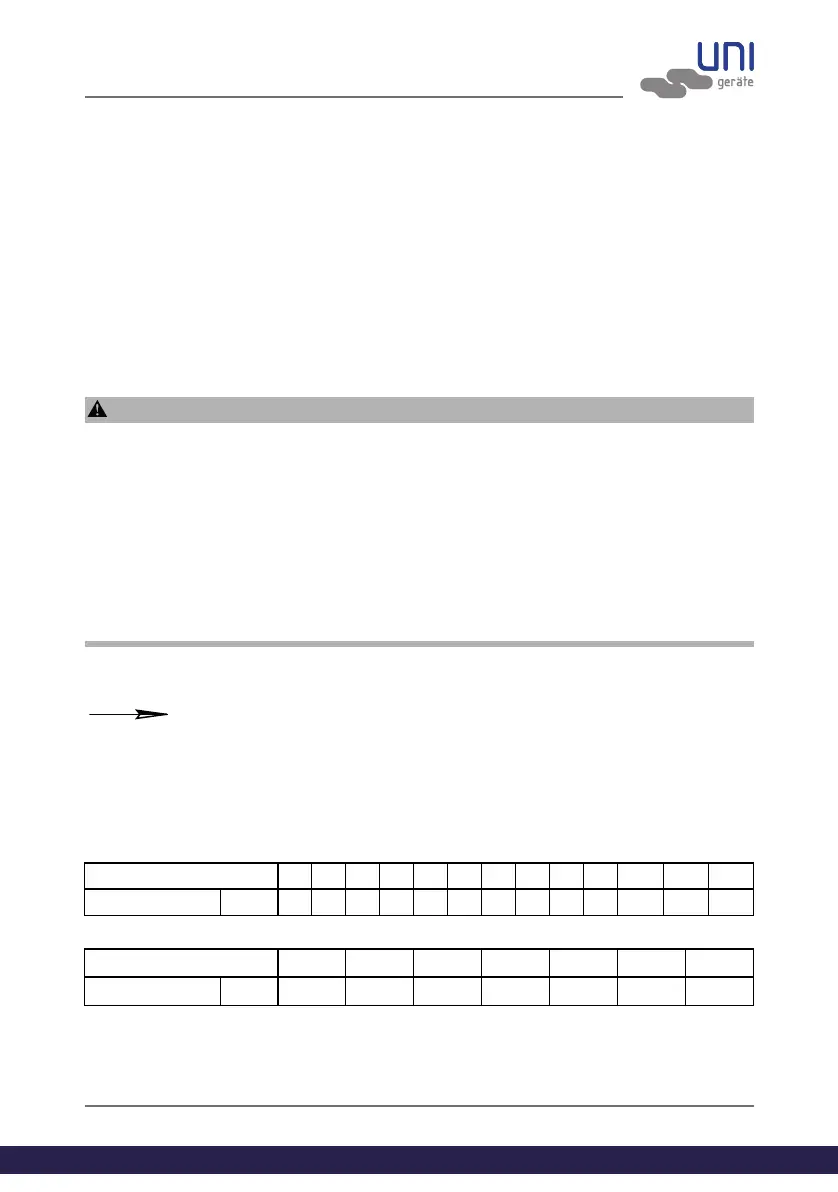

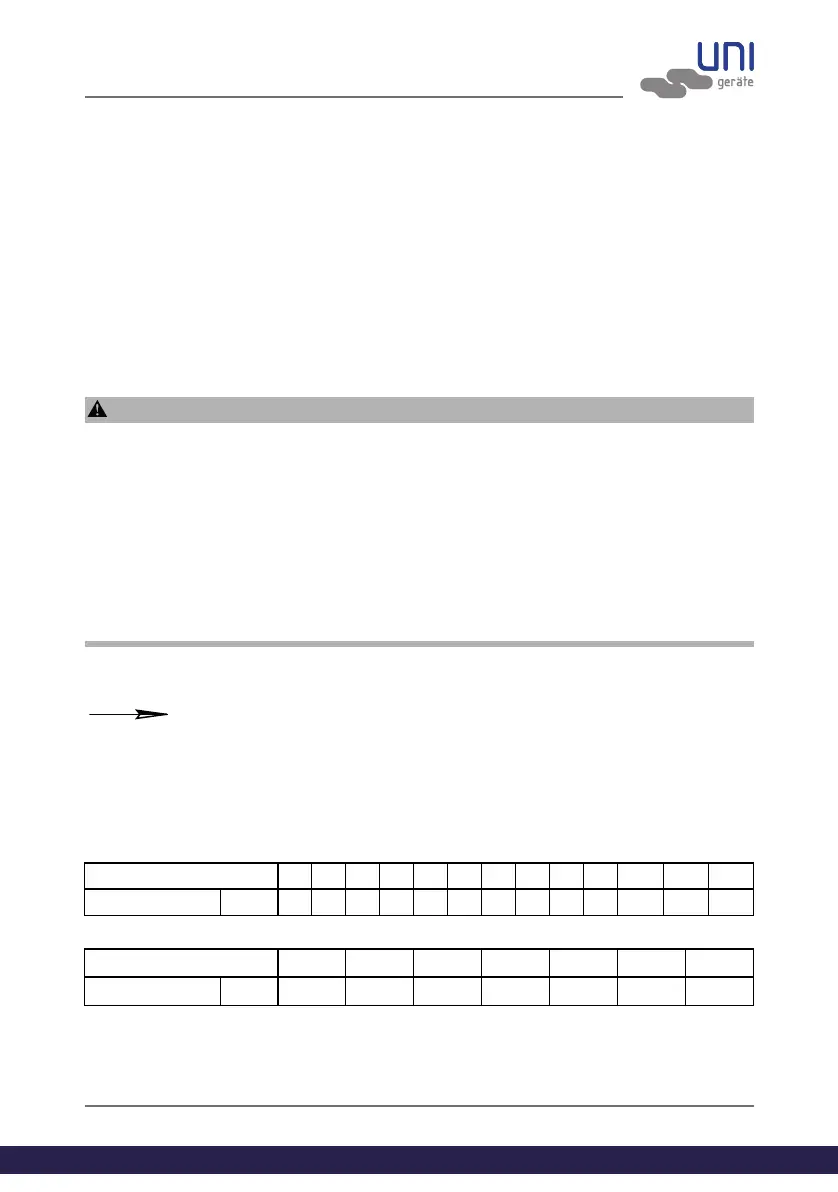

Tightening torques

Greased pipe screws

Greased product bolts and nuts

DN 8 101520253240506580100 125≥150

Torque Nm 20 30 30 30 30 50 50 50 50 50 80 160 160

Bolt M6 M8 M10 M12 M16 M20 M24

Torque Nm 5 11 22 39 70 110 150

Loading...

Loading...