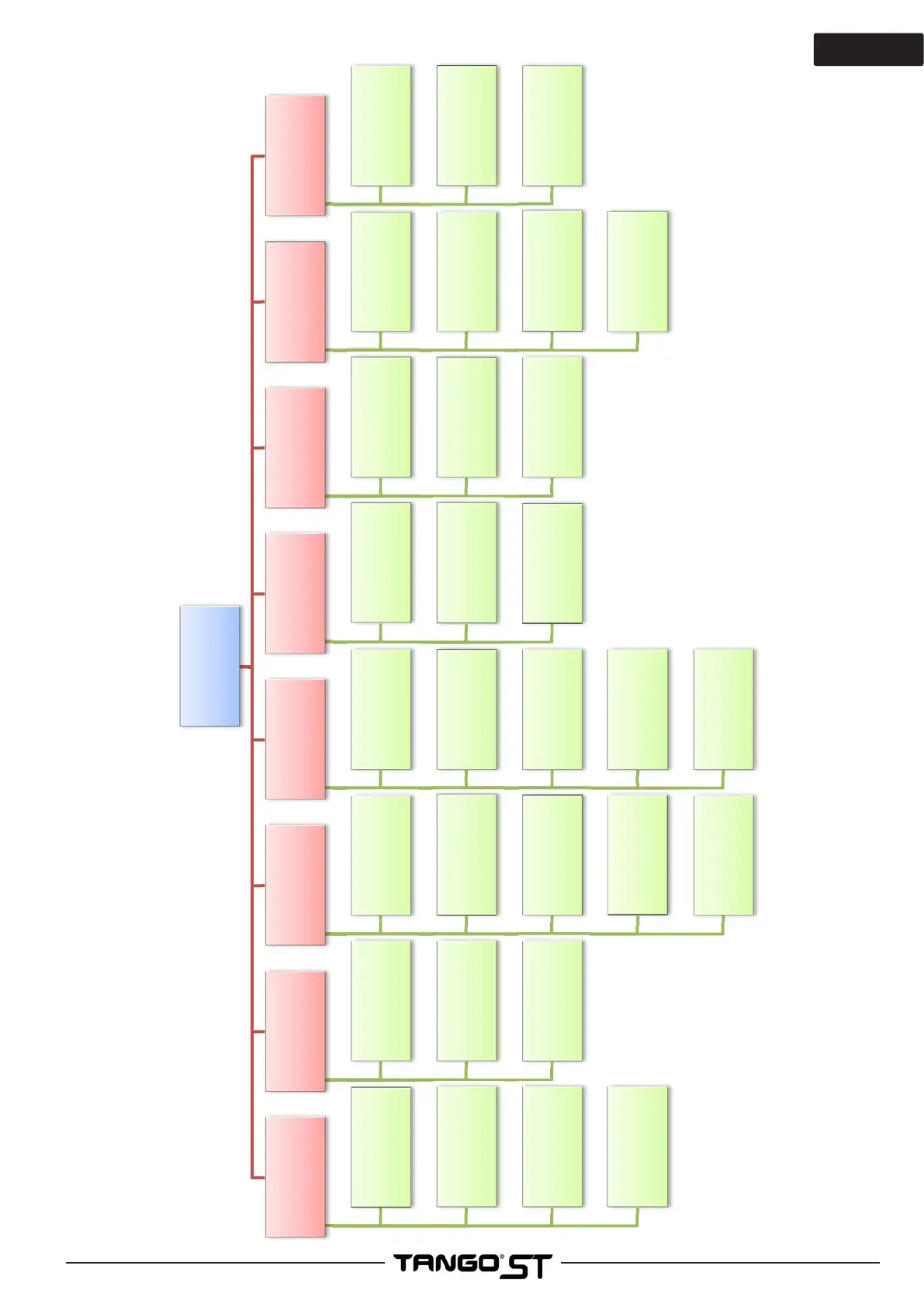

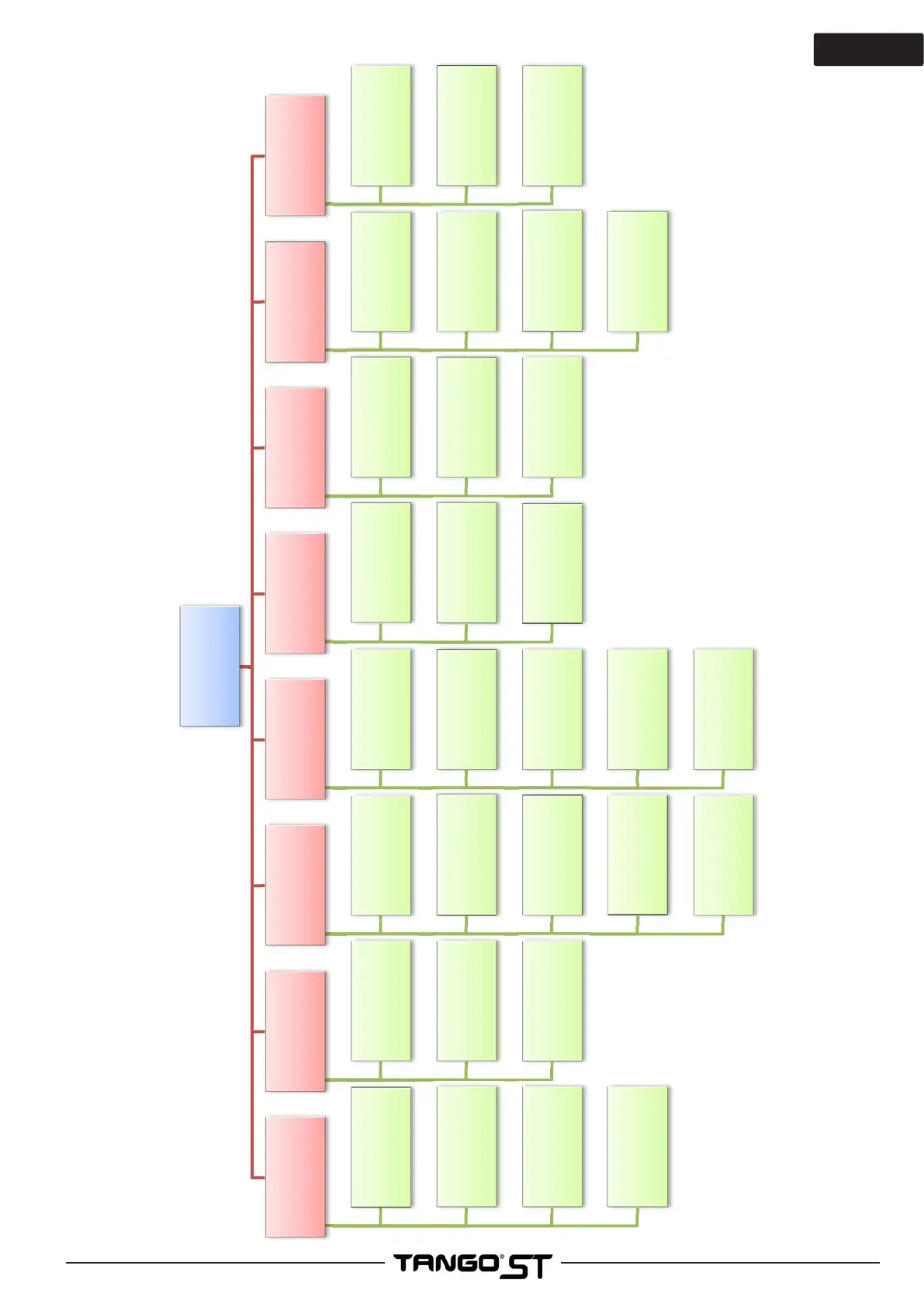

FOAM

Not hot enough

Check steam boiler pressure

+-1.1bar

Check the pump speed

(between 20% and 35%)

Check the EVVS solenoid

valve heating circuit (coil

heating)

Check the coil; it must be

clogged.

Dose problem

Check the inlet nozzle

(refrigerator tube)

Check the milk time in

seconds (product settings)

Check pump rotation speed,

replace if necessary

No foam

Check EVALC (hot milk) or

EVALF (cold milk)

Check that the hot water valve

is not clogged

Check the pump speed in

relation to the product (hot

10-15%/ cold 50-

70%

Disconnect the hot water

valve, run a cycle, if presence

foam with spitting problem of

air entry (check

EVALF/EVALC)

Change the pump

Poor quality foam

Check milk temperature

between 3°C and 8°C

Check the "advanced milk

settings" (see of adjustment

sheet)

Review the air settings

(flush first)

Check the tightness of the

entire hydraulic circuit

Change the pump

Foam too dense

Check the pump speed in

relation to the product (hot 10-

15%/ cold 50-

70%

Reduce hot air if hot product

Reduce cold air if cold product

Foam not dense enough

Check the pump speed in

relation to the product (hot 10-

15%/ cold 50-

70%

Increase hot air if hot product

Increase cold air if cold

product

Bubbly foam or spitting from

the nozzle

Check the refrigerator module

circuit for air leaks

Check the hot water non-

return valve, change if

necessary

Check the pump union / EVNL

Check the sealing of the

hot/cold air EVALF/EVALC SV

Cold milk / not cold enough

Check the milk in the

refrigerator (check the

calibration)

Check EVLCF; it must be in

operation during a cold cycle.

If EVLCF does not operate

check the presence of 24

VDC; if OK replace the

solenoid valve

Foamsystemdiagnosis; follow step by step

from the top to the bottom,

for each element.

Loading...

Loading...