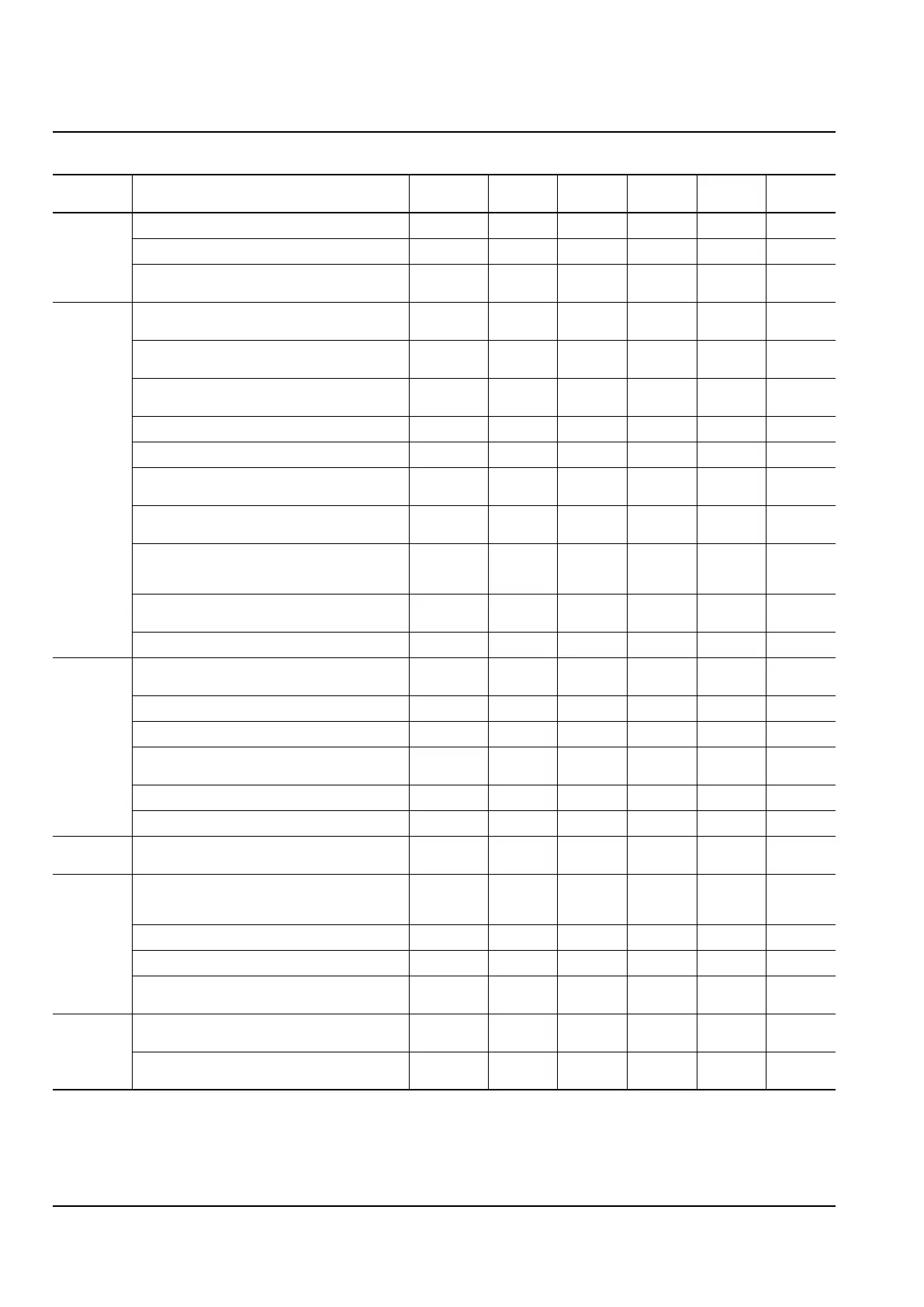

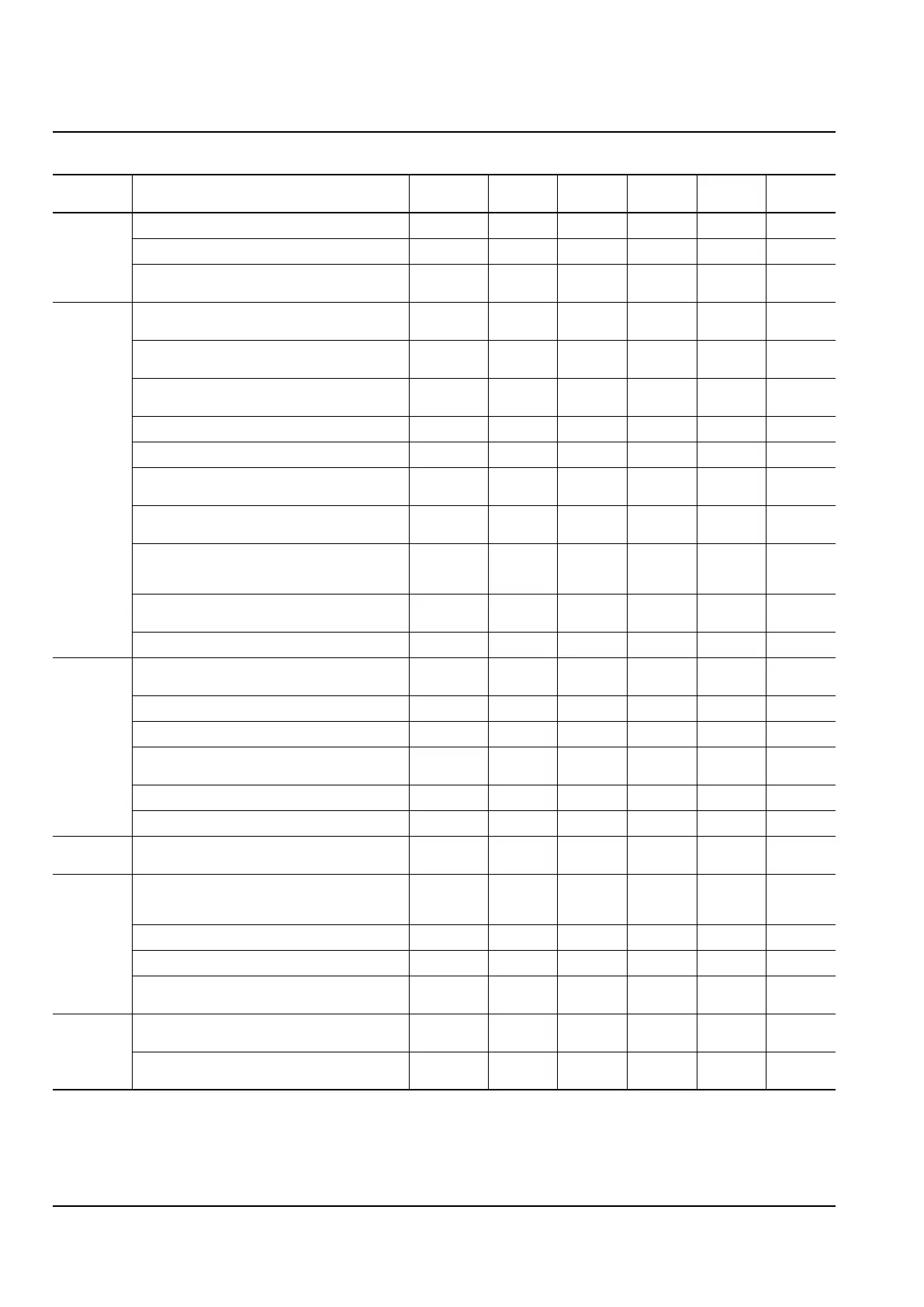

LOAD HANDLING SYSTEM

Checking

item

Service Required Tools Daily

Monthly

(200 hrs)

Trimonthly

(600 hrs)

Semiannually

(1200 hrs)

Annually

(2400 hrs)

Forks

Check for damage, deformation or wear. Visual

○ ○ ○ ○ ○

Check fork stopper pin for damage or wear. Visual

○ ○ ○ ○ ○

Check for roots and teeth welded area for

cracks or wear.

Visual

○ ○ ○ ○

Mast and

carriage

Check mast cross members for cracked weld or

damage.

Visual

○ ○ ○ ○

Check tilt cylinder bracket and mast for cracks

or damage in welded areas.

Visual

○ ○ ○ ○

Check outer and inner masts for cracked weld

or damage.

Visual

○ ○ ○ ○

Check carriage for cracked weld or damage. Visual

○ ○ ○ ○

Check roller bearing for looseness. Touch

○ ○ ○ ○

Check mast support bushing for wear or

damage.

Visual

○

Check mast support cap bolts for looseness.

Torque

wrench

○ (rst

time only)

○ ○

Check for looseness of lift cylinder tail bolts,

piston rod head bolts, U bolts, piston head

guide bolts.

Test

hammer

○ (rst

time only)

○ ○

Check rollers, roller pins and welds for cracks or

damage.

Visual

○ ○ ○ ○

Check the mast for proper operation. Operate

○ ○ ○ ○ ○

Chains and

sheaves

Check chains for tension, deformation, damage

or corrosion.

Touch

○ ○ ○ ○ ○

Check chains for elongation. Gauge

○ ○ ○ ○

Lubricate chains. Operate

● ● ● ●

Check loose linkage of chain anchor pin and

chain.

Visual

○ ○ ○ ○

Check sheaves for deformation or damage. Visual

○ ○ ○ ○

Check sheave bearings for looseness. Touch

○ ○ ○ ○

Attach-

ments

Check for operation and installation.

Operate/

visual

○ ○ ○ ○

Cylinder

Check piston rod, rod bolt, rod end for

looseness, deformation or damage.

Visual/

test

hammer

○ ○ ○ ○ ○

Check for proper operation. Operate

○ ○ ○ ○ ○

Check for oil leaks. Visual

○ ○ ○ ○ ○

Check pin and cylinder bushing for wear or

damage.

Visual

○ ○ ○ ○

Hydraulic

pump

Check for oil leaks or noise.

Visual/

auditory

○ ○ ○ ○ ○

Check drive for wear.

Visual/

auditory

○

4-45

Loading...

Loading...