9

EN

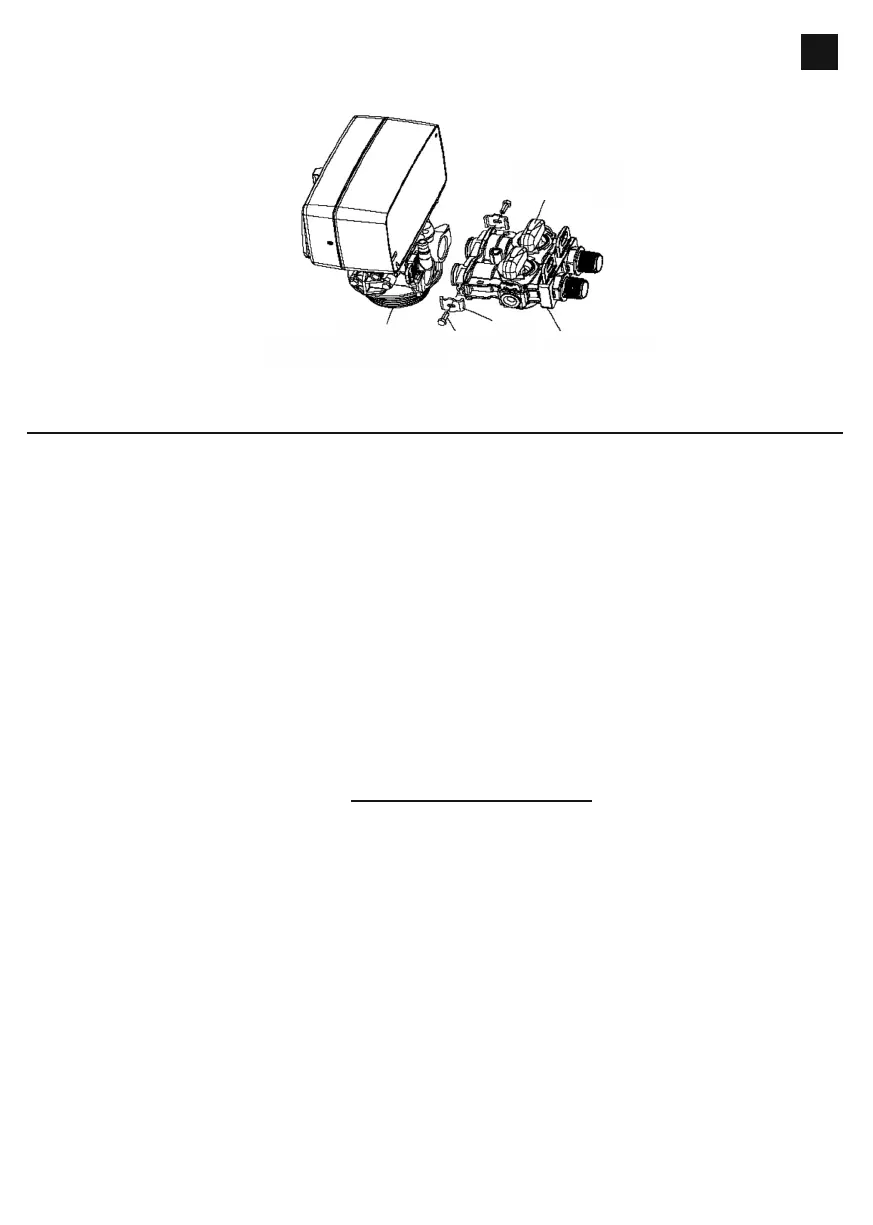

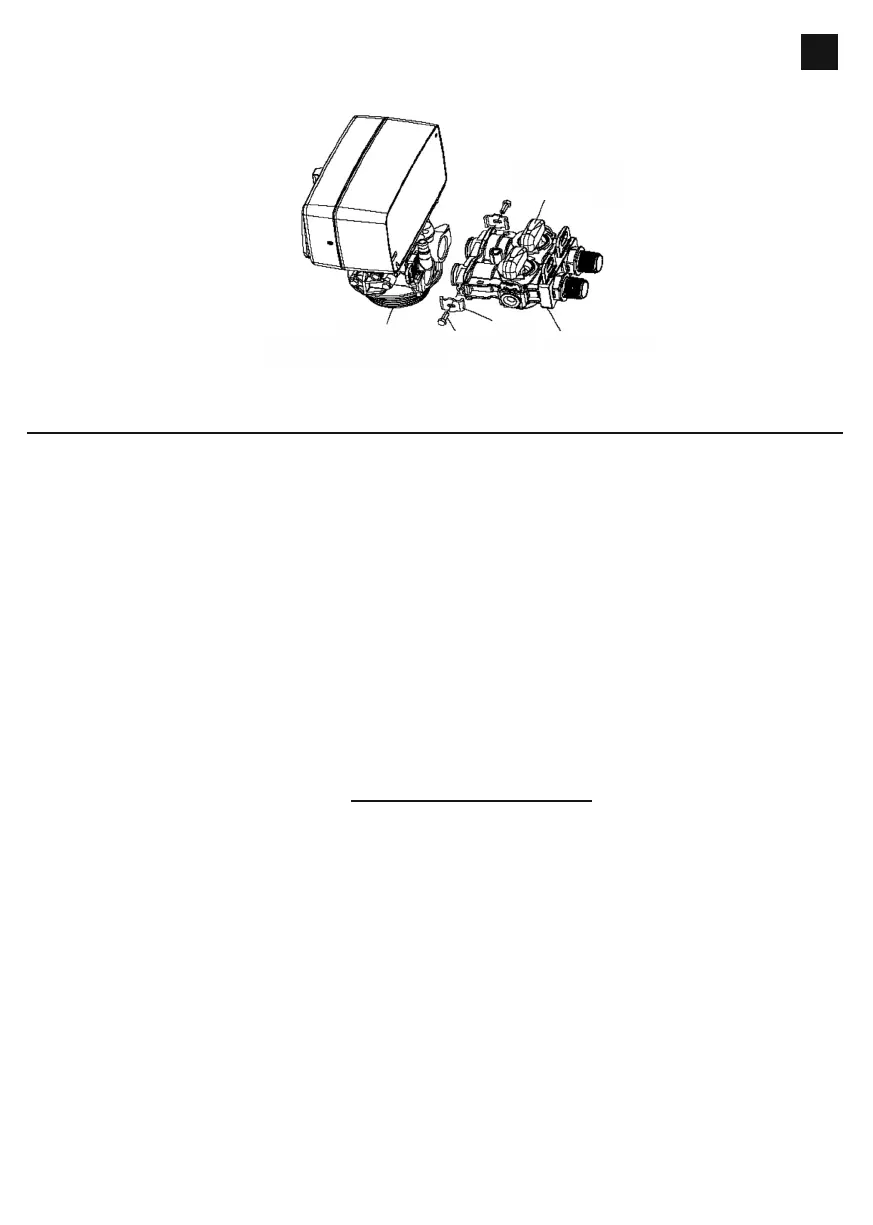

Control heads in the case of both devices are connected according to the illustration below, elements necessary for the

connection are included in the set.

the bypass valve

fig.1

the head

body

screw

fastener

the bypass body

REG.CAP. =

Assembly

3. Notes

- Hot water can seriously damage the water soening system. In the case of installation near a boiler, a non-return

valve should be installed in the hot water tank or on the supply line between the device and the tank

- The pressure of delivered water on the input must be contained in the range 2.5 to 4 bar

- The required ambient temperature for the soener is 1-30°C. The soener must be protected against frost

- ONLY SALT TABLETS should be applied as a means for regenerating the bed

- Before the assembly of the control head, an appropriate injector and restrictor should be necessarily selected (see the

head operating instructions, p. 13) - concerns two-element devices.

4. BNT head programming

ion-exchange ability

hardness d

The detailed diagram of head programming is contained in the BNT head operating instructions on page 8.

However, it is recommended to read the whole head operating instructions before you begin programming.

In order to calculate the amount of water between regenerations - REG.CAP. the station ion-exchange ability given in the

table should be divided by the feed water hardness in German degrees.

E.g. I have a ST-40 soener - vessel 40l. Ion-exchange ability

of this station is 114 0dT. Hardness of my water is 150d. That is 1140d / 150d = 7.6T. Thus, the value in this example is 7.6

Loading...

Loading...