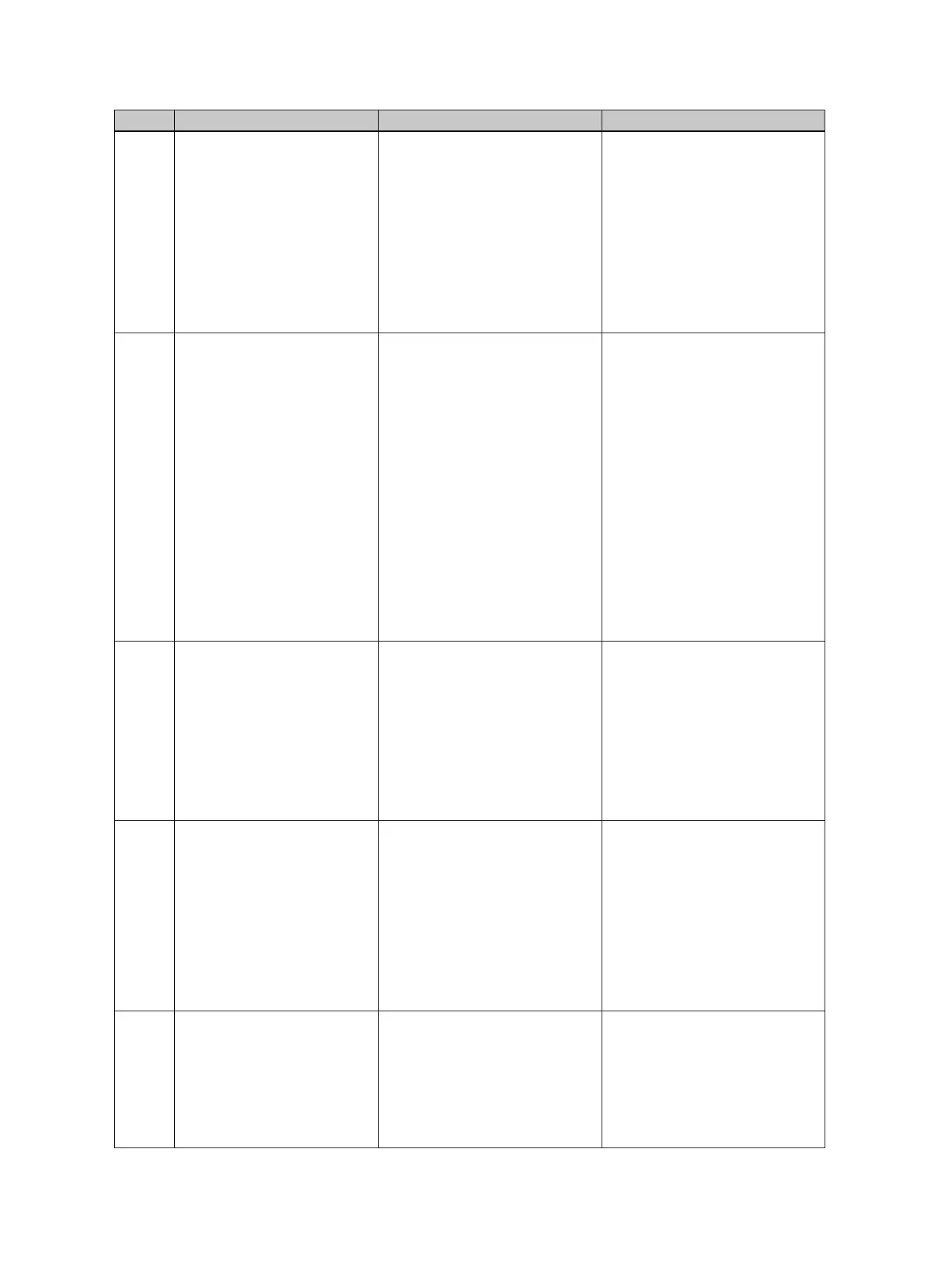

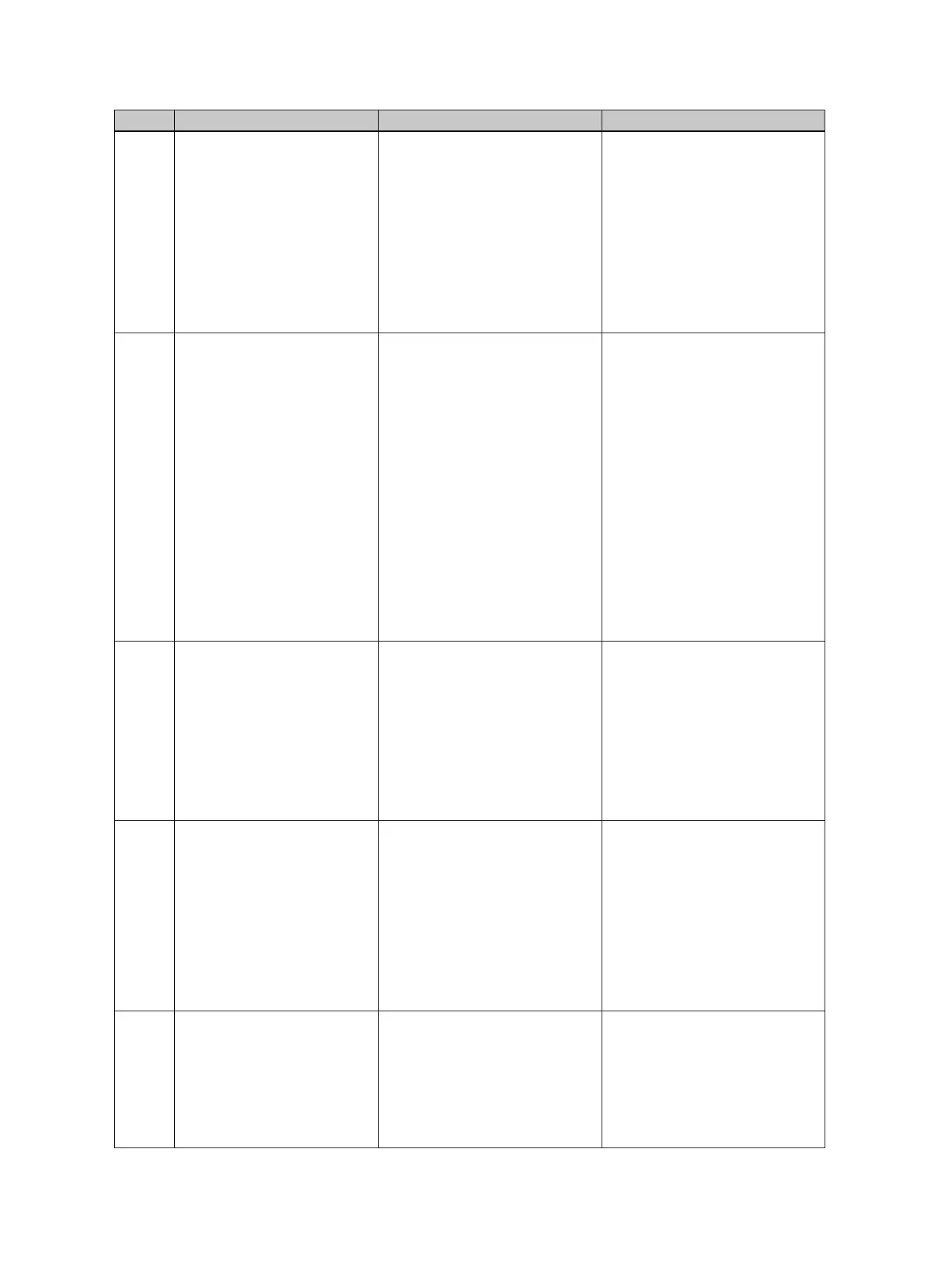

Appendix

32 Installation instructions Heat pump control interface module 0020291573_00

Code Meaning Cause

Remedy

F.735 Evaporation temperature too high – Temperature in the environment

circuit (heating mode) or building

circuit (cooling mode) too high for

compressor operation

– Feed-in of external heat into the

environment circuit due to increased

fan speed

– Check the system temperatures

– Check the refrigerant filling volume

for overfilling

– Check the EEV (does the EEV

move to the limit stop? Use

sensor/actuator test)

– Check the sensor for the evaporation

temperature (depending on the

position of the 4-port diverter valve)

– Check the volume flow in cooling

mode

– Check the air volume flow in heating

mode

F.737 Condensation temperature too

high

– Temperature in the environment

circuit (cooling mode) or building

circuit (heating mode) too high for

compressor operation

– Feed-in of external heat into the

building circuit

– Refrigerant circuit overfilled

– Insufficient flow rate in the building

circuit

– Reduce or stop the external heat

that is entering

– Check the back-up heater (heats

up even though it is off in the

sensor/actuator test?)

– Check the EEV (does the EEV

move to the limit stop? Use the

sensor/actuator test)

– Check the compressor outlet sensor,

compressor outlet temperature

sensor (TT135) and high-pressure

sensor

– Check the refrigerant filling volume

for overfilling

– Check whether the service valves on

the outdoor unit are open.

– Check the air volume flow in cooling

mode for sufficient flow rate

– Checking the heating pump

– Check the building circuit flow rate

F.741 Building circuit: Return temp. too

low

– During the de-icing, the return tem-

perature falls below 13 °C

– Ensure the minimum installation

volume is maintained; if required,

install a series return cylinder

– The fault message is displayed until

the return temperature increases to

above 20 °C.

– Activate the electric back-up heater

in the product's control panel and

in the system control in order to

increase the return temperature. The

compressor is blocked while the fault

message is present.

F.752 Fault: Frequency converter – Internal electronics fault on the in-

verter PCB

– Mains voltage outside of 70 V–282 V

– Check the integrity of the power sup-

ply cables and compressor connec-

tion cables

The plugs must audibly click into

place.

– Check the cable

– Check the mains voltage

The mains voltage must be between

195 V and 253 V.

– Check the phases

– Replace the frequency converter, if

required

F.753 Connection fault: Freq. conv.

n.recogn.

– Missing communication between the

frequency converter and the outdoor

unit's control PCB

– Check the integrity of the cable

harness and plug connection and,

if required, replace them

– Check the frequency converter by

actuating the compressor safety

relay

– Read the assigned parameters for

the frequency converter and check

whether values are displayed

Loading...

Loading...