VALMAR Operation

Page 13

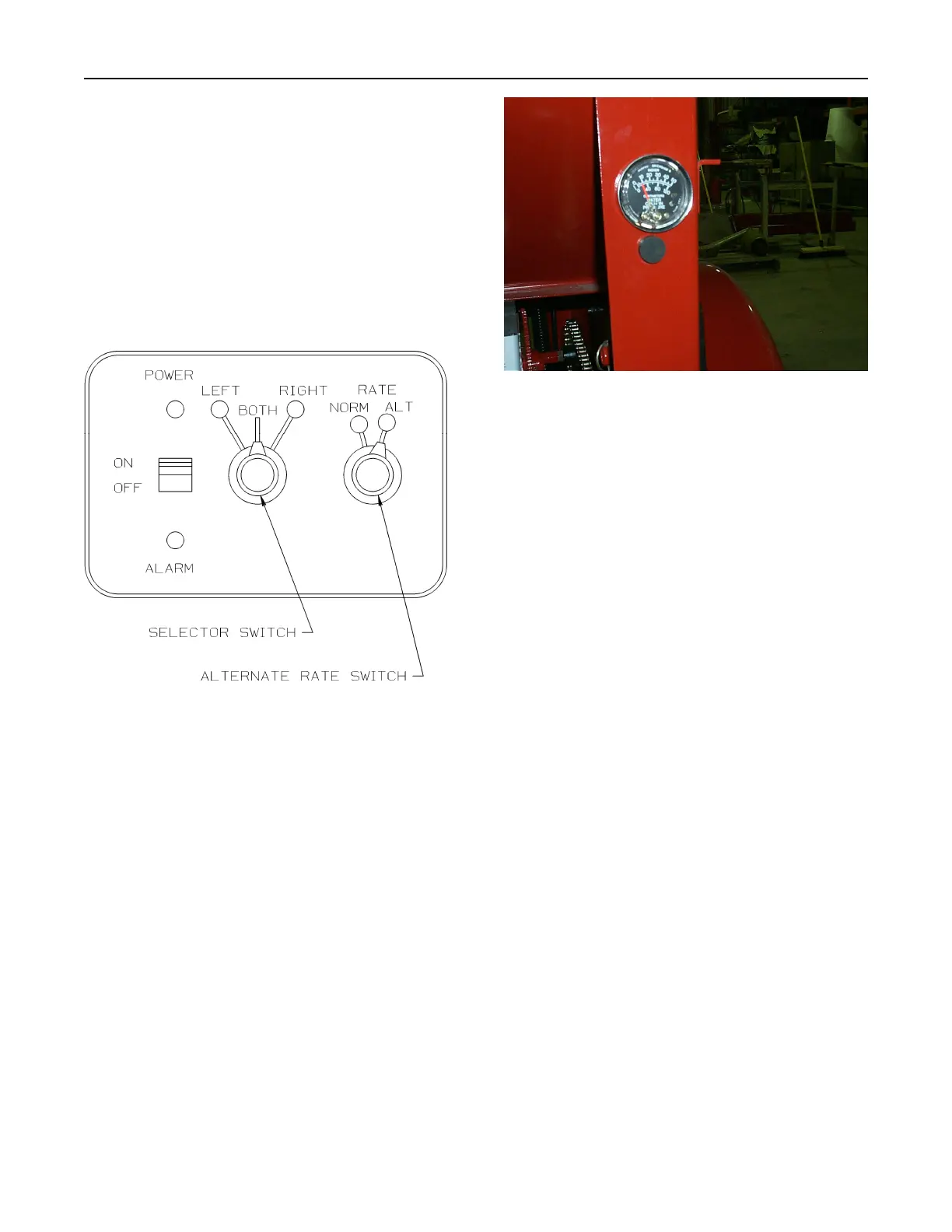

The green light indicates NORMAL rate and the

yellow light indicates ALT (alternate) rate.

Assembly procedures are contained in the

alternate rate kit itself.

Pressure Alarm

The red ALARM light and buzzer alerts the

operator to inadequate or excessive air manifold

pressure. The light and buzzer are activated by

the manifold pressure gauge. Refer to Manifold

Pressure Gauge in the Operation Section.

Figure 4 - 2: Control Unit

Manifold Pressure Gauge (Figure 4-2)

The manifold pressure gauge indicates proper

fan speed by measuring air pressure in the

manifold in inches (cm) of water column. The

pressure gauge includes a low pressure contact

set at 10 inches and a high pressure contact set

at 25 inches. The gauge is wired to the pressure

alarm light on the control unit. The pressure

alarm light will light up for two reasons:

1. The air pressure is below 10 inches.

2. The air pressure is above 25 inches.

Proper fan speed is achieved at a manifold

pressure of 17 inches of water column. Fan

speed is set by adjusting the speed of a gas

engine or a hydraulic motor which drives the

fan.

Figure 4 - 3: Pressure Gauge

Gas Engine Fan Drive (Optional)

The 2055 can be equipped with a 9 hp Honda

engine. The 2455 and 3255 can be equipped

with an 11 hp Honda engine.

Refer to the Honda Owner’s Manual for correct

startup and operation of the engine.

The engine is equipped with centrifugal clutch

that engages at 1600 rpm. Below that speed the

fan will not operate.

Hydraulic Fan Drive (Figure 4-4)

Operation of the hydraulic fan drive requires an

oil flow of 10.5 U.S. gpm for the 2055 and 2455,

and 11.5 U.S. gpm for the 3255.

The major components of the hydraulic fan

drive are:

1. the hydraulic motor for operating the fan.

2. The flow control valve for adjusting fan

speed.

There are two basic tractor hydraulic systems:

the Open Center system and Closed Center

System. Contact your tractor dealer to establish

which system you have. Set your fan speed as

follows:

Loading...

Loading...