Adjustments & Service Valmar

Clutches Do Not Release

The clutches should release when electrical

power is shut off. If metering rollers continue to

turn, inspect clutches for improper assembly.

Check the following:

1. Check bearings for corrosion, damage or

failure. They can cause the clutch to engage

improperly or drag.

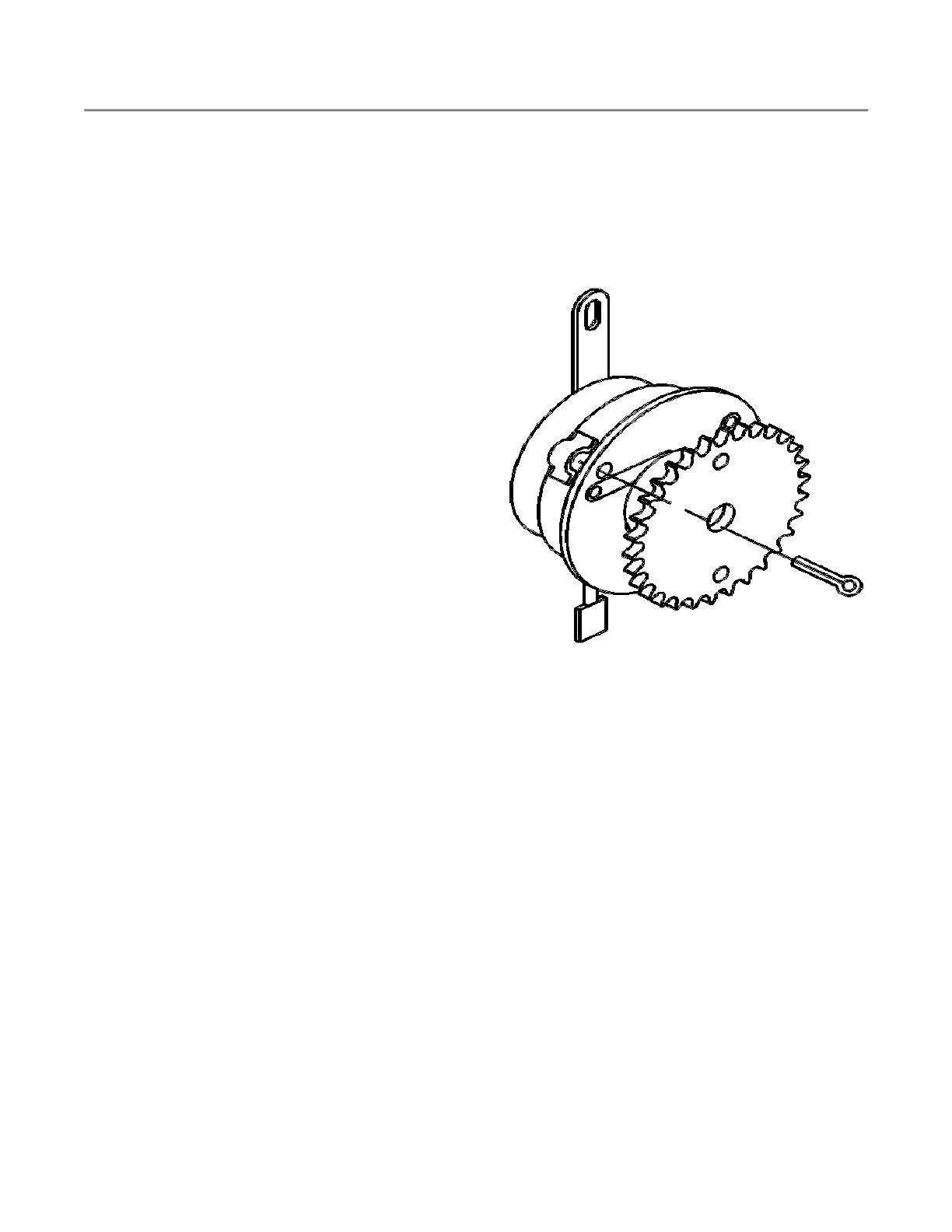

2. Insufficient gap at clutch armature. If the

clutch armature contacts the rotor ring when

power is disconnected, add a spacer ring to

provide the 1/32 inch clearance between the

armature and rotor as indicated in the

diagram.

Clutches Do Not Engage

Raise ground drive wheel. Energize the

clutches by turning the control unit ON. Use

another 12 volt source if tractor is not attached.

Rotate wheel by hand and observe clutches to

see if they engage. If they do not engage

1. Check for electromagnetic attraction. Touch

the armature using a wrench or screwdriver

to see if it attracts metal. If there is no

magnetic pull, check the following:

a) Check the control unit. The Power

Switch must be ON. Check the

Normal/Alternate Switch to make

sure it is in the proper position.

b) Check the fuses to the control unit.

Refer to Fuses in this section.

c) Check connections to the power

source (battery).

d) Check all connections along

harness.

e) Check ohm resistant readout at

clutch. It should be between 2.4 and

2.8 ohms at room temperature.

2. There is magnetic pull, but no clutch

engagement. Check the following:

a) Check gap in the clutch. A gap

greater than 1/32 inch indicated in

Figure 6-1 means the spacer ring

should be removed.

b) If there is no spacer ring and gap is

greater than required, see your

Valmar dealer.

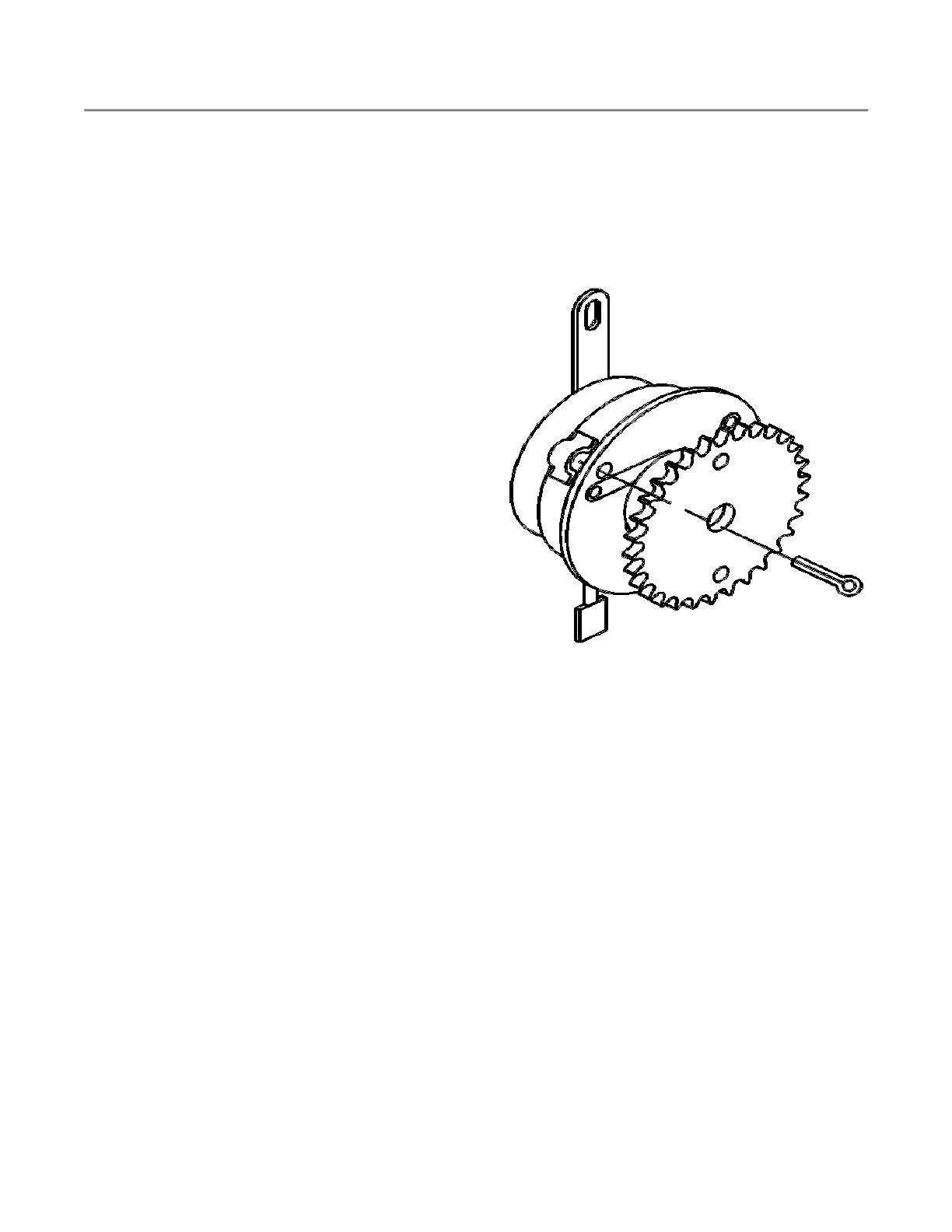

Clutch Lockup (Fig. 6-2)

Figure 6 - 2: Clutch Lockup

The electromagnetic clutches can be manually

engaged should an electrical failure by inserting

a 1/8” dia. pin through both clutch halves as

shown.

Gas Engine

Refer to the Honda engine Operator’s Manual

for correct engine maintenance procedures.

Centrifugal Clutch (Fig. 6-3)

The centrifugal clutch is secured to the engine

using Loctite 609. Should only the bearing

require replacement, do not remove the clutch

assembly from the engine output shaft. This will

prevent the breaking of the Loctite seal.

Bearing Replacement

The bearing can be replaced without removing

the clutch from the engine as follows:

Loading...

Loading...