Valmar Adjustments & Service

Page 31

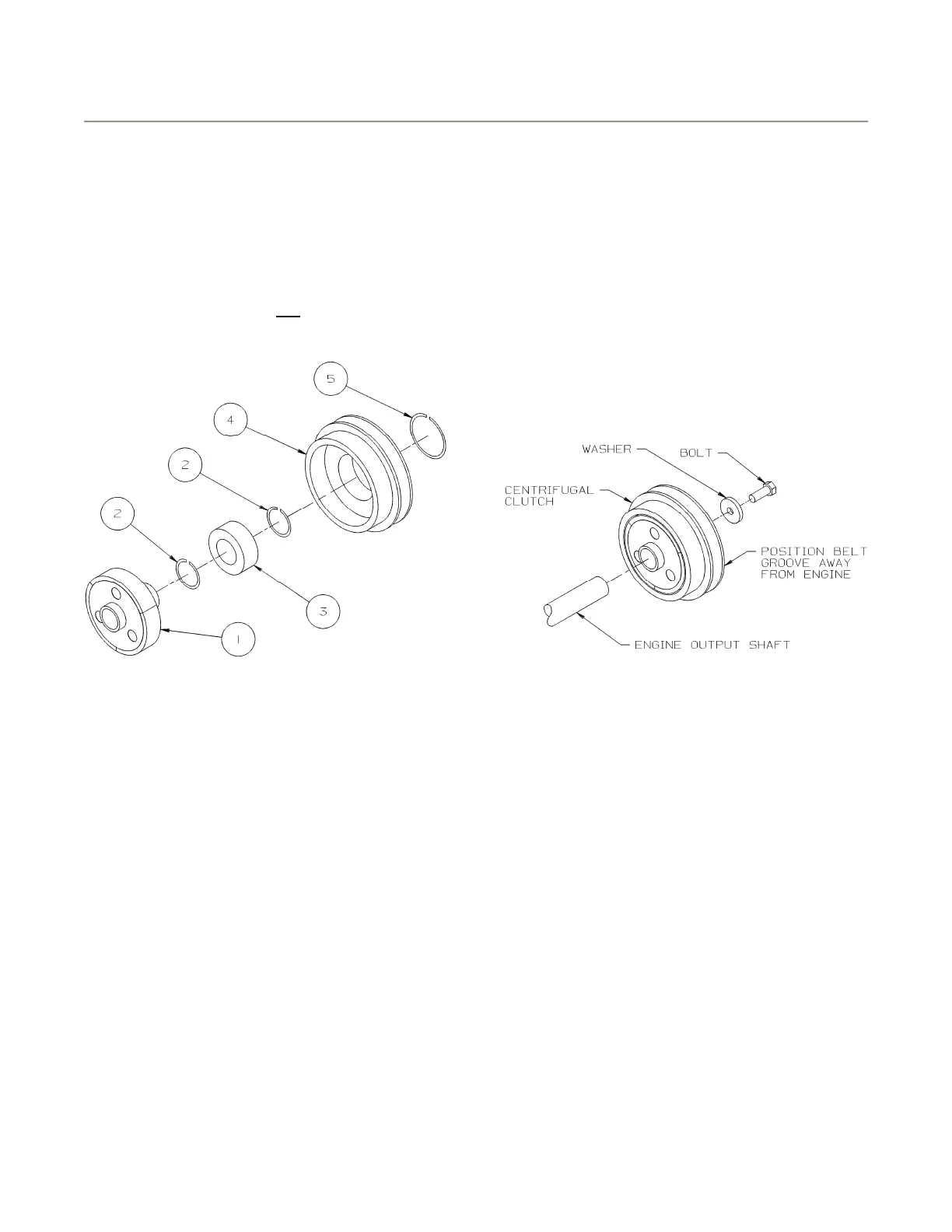

1. Remove the snap ring (5) and the pulley (4)

from the clutch rotor and hub (1).

2. Remove one snap ring (2) which holds the

bearing in place within the pulley and press

out the bearing.

3. Reinstall the components in reverse order of

removal. Install the new bearing by pressing

on the inner race, not the balls of the

bearing.

Figure 6 - 3: Bearing Replacement

Clutch Removal

If the clutch or pulley is damaged and needs to

be completely removed from the engine, do so

as follows:

1. Remove the retaining bolt and washer from

the end of the crankshaft.

2. Heat the Loctite securing the clutch to 350 to

400 degrees F. Direct the heat to the

connection point only. Do not overheat the

crankshaft as this may weaken it.

3. Using a puller, remove the clutch from the

engine while hot.

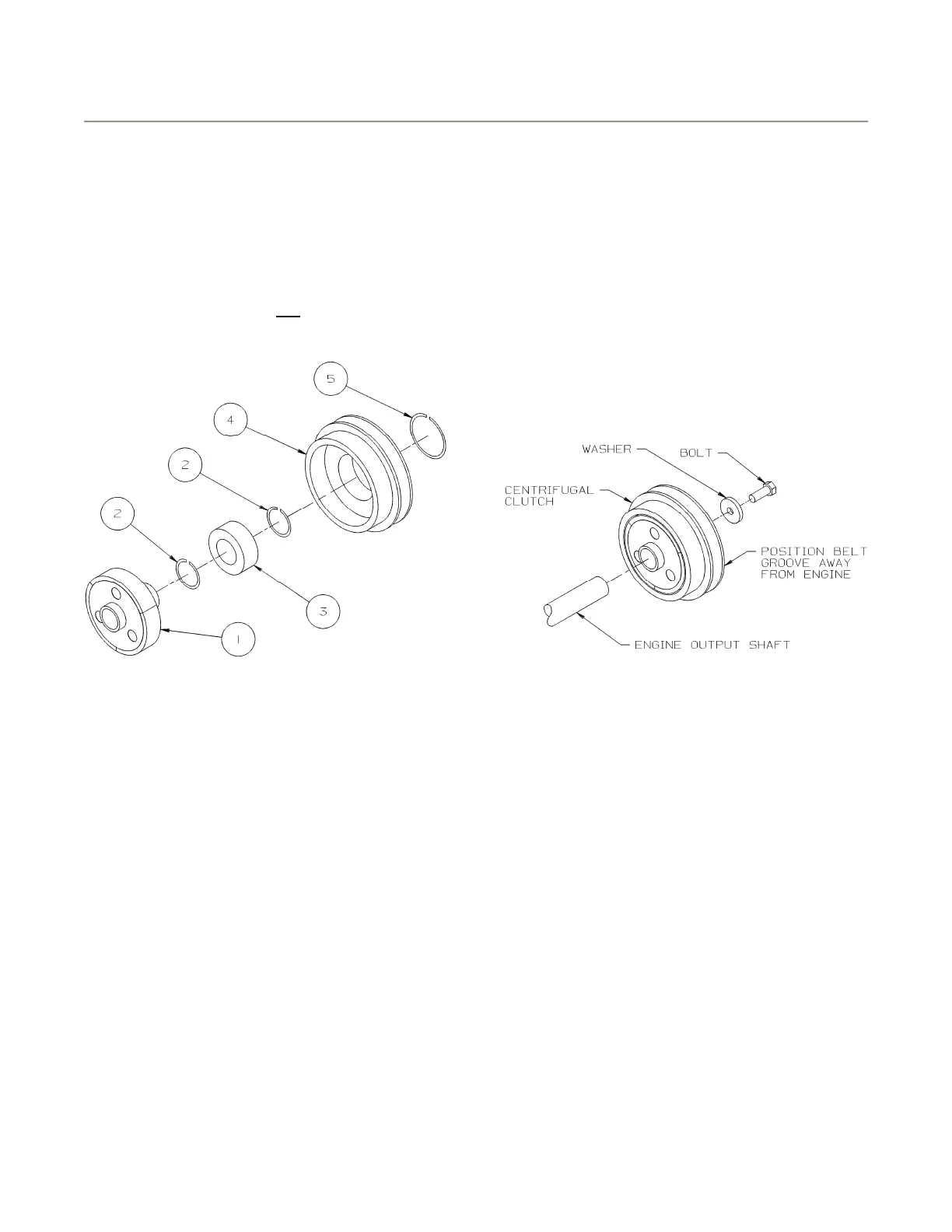

Clutch Reinstallation

1. Check the bearing seals for heat damage.

Replace if necessary.

2. Remove old Loctite from the clutch and

engine output shaft. Clean thoroughly using

a chlorinated solvent. Wipe dry.

3. Apply Loctite 609 evenly to both mounting

surfaces. Do not fill the keyway.

4. Install clutch to engine with the belt groove

away from the engine. Wipe off excess

Loctite.

5. Reinstall washer and retainer bolt. Do not

Loctite the washer.

6. Cure Loctite for 6 hours at a temperature of

68 to 70 degrees F before operating. If

temperature falls to 50 degrees F, allow 24

hours for curing.

Figure 6 - 4: Clutch Installation

Fan Drive

1. Start up the fan and run at the

recommended RPM until the manifold,

venturis and hoses are blown dry by the

airflow.

2. Check airflow at the house outlets with

the fan running at operating pressure. If

an outlet lacks sufficient air velocity,

check the manifold venturis and hose for

any blockage. Unplug as required.

3. Check that all bearings turn freely.

Replace any that are rough or seized.

4. Check all hardware. Tighten all loose

bolts and replace any that are missing.

Use Grade 5 or better when replacing

bolts.

Loading...

Loading...