9

3.0

INSTALLATION (CONT’D)

3.5 Connecting Duct to the Unit

Insulated flexible duct:

Use the following procedure for connecting the insulated flexible duct to

the ports on the unit (exhaust to outside and fresh air from outside).

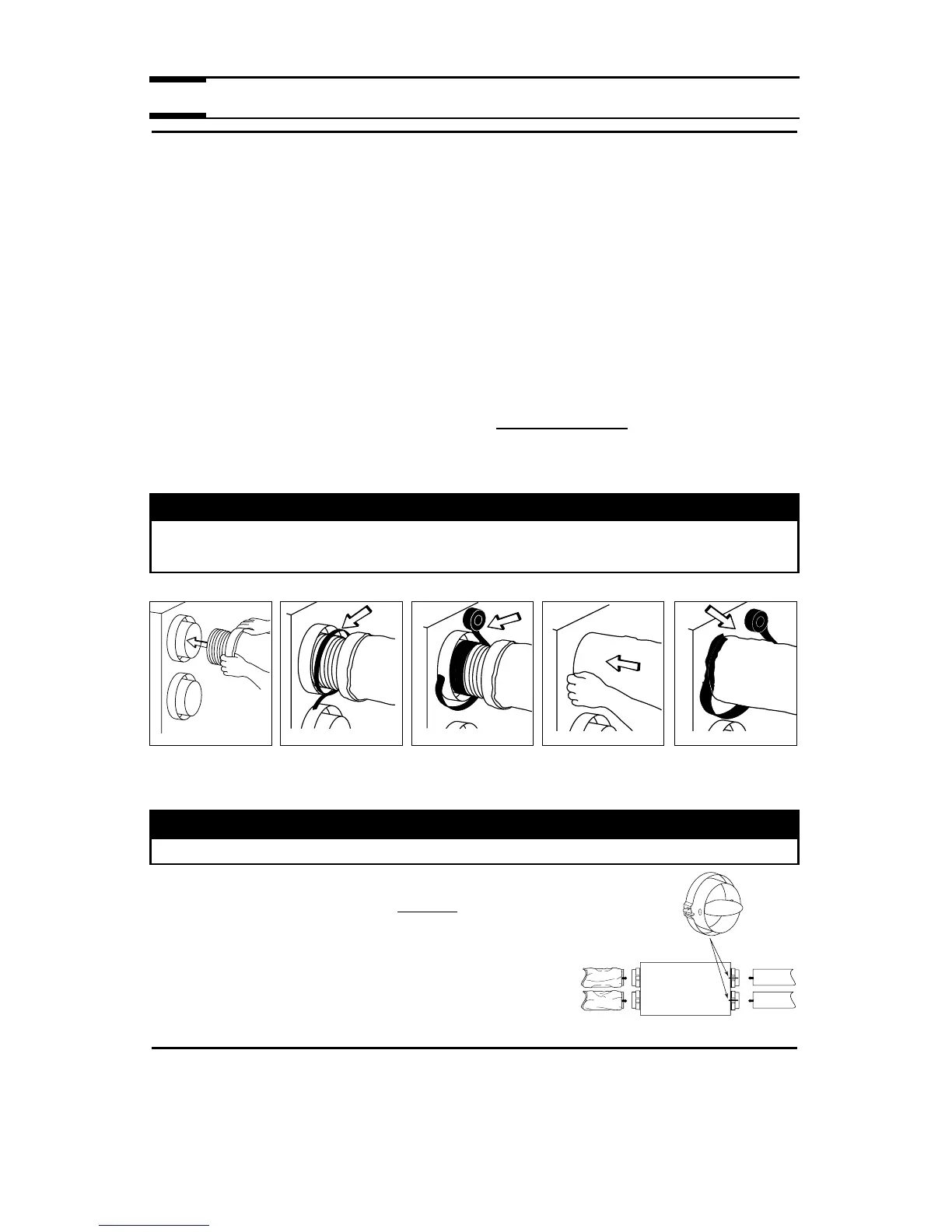

a) Pull back the insulation to expose the flexible duct.

b) Connect the interior flexible duct to the opening using a duct tie.

c) Carefully seal the connection with duct tape.

d) Pull the insulation over the joint and tuck it between the inner and

outer rings of double collar.

e) Pull the vapor barrier over the insulation and over the outer ring of the

double collar.

f) Apply duct tape to the joint making an airtight seal.

Avoid compressing

the insulation when you pull the tape tightly around the joint. A

compressed insulation loses its R value and causes water dripping

due to condensation on the exterior surface of the duct.

a) b) c) d), e) f)

Rigid duct:

Use duct tape to connect the rigid ducts to the ports.

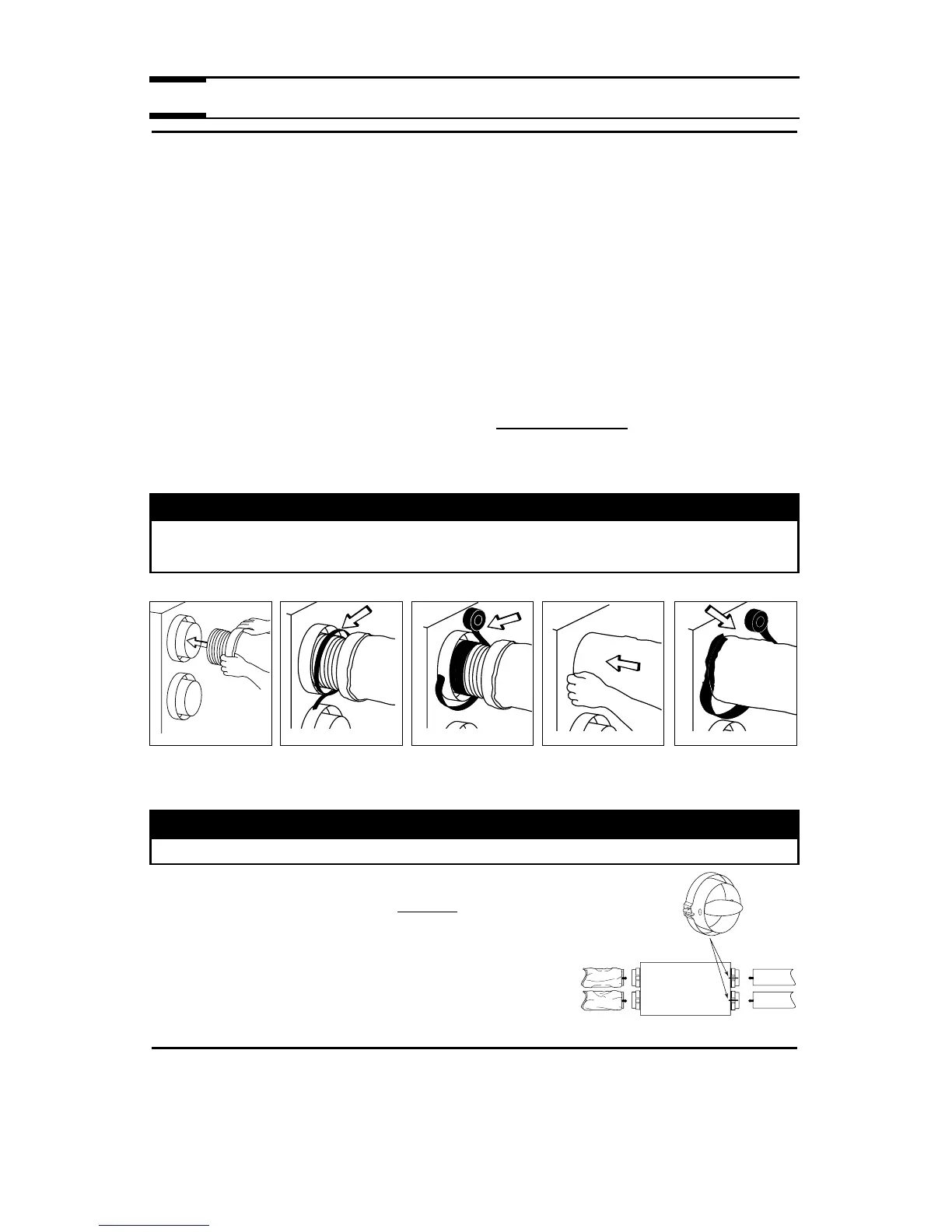

Make sure that the 2 balancing dampers are

left in a fully open position befor

e connecting

the ducts to these ports (fresh air distribution

port and stale air exhaust port as shown on

figure 13 beside).

3.6 Installing Exterior Hoods

Choose an appropriate location for installing the exterior hoods:

• a minimum distance of 6 feet (1.8 m) between hoods to avoid

cross-contamination

• a minimum distance of 18 inches (457 mm) from the ground

CAUTION

Make sure that the vapor barrier on the insulated ducts does not

tear during installation to avoid condensation within the duct.

CAUTION

Do not use screws to connect rigid ducts to the ports.

VJ0011

Loading...

Loading...