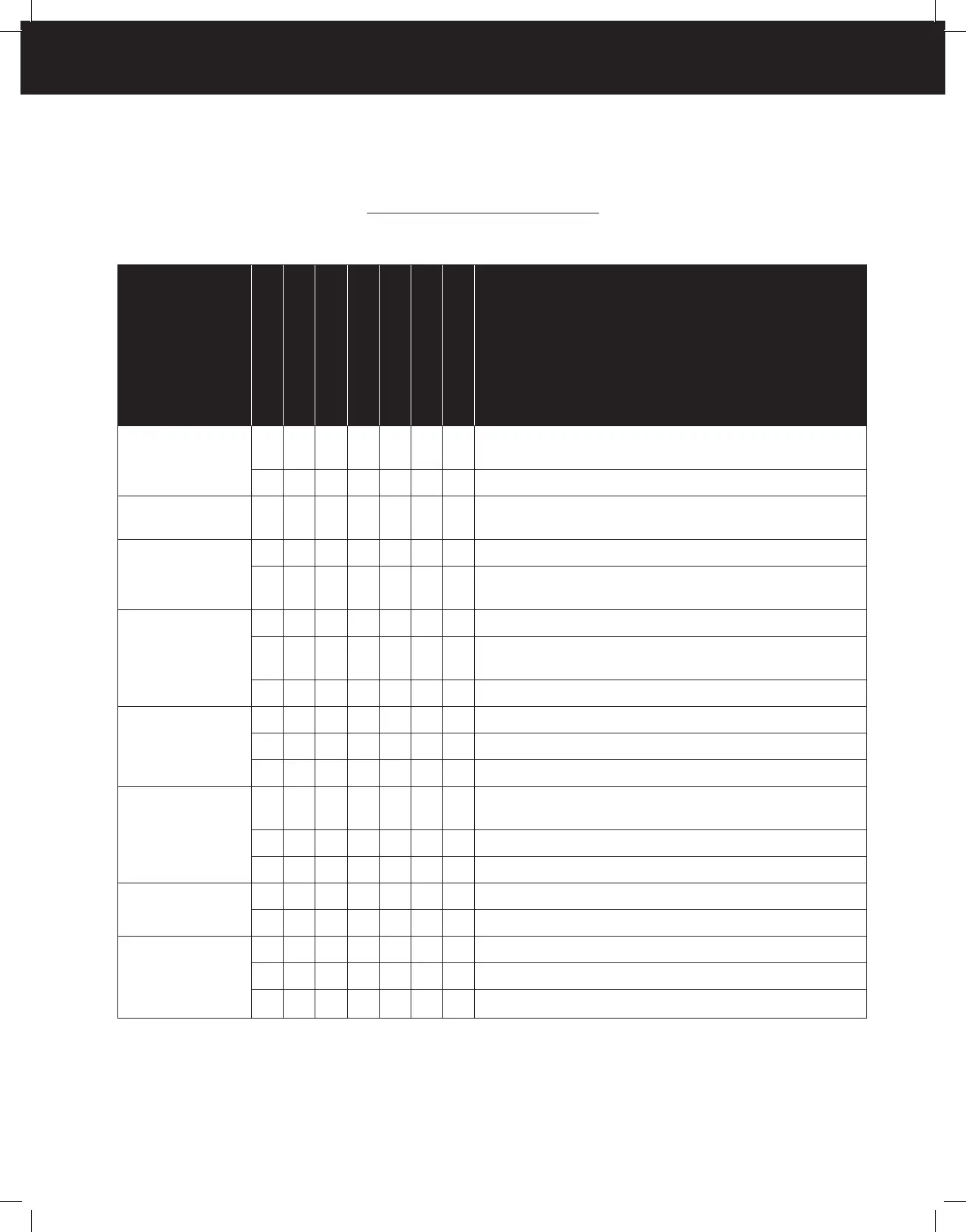

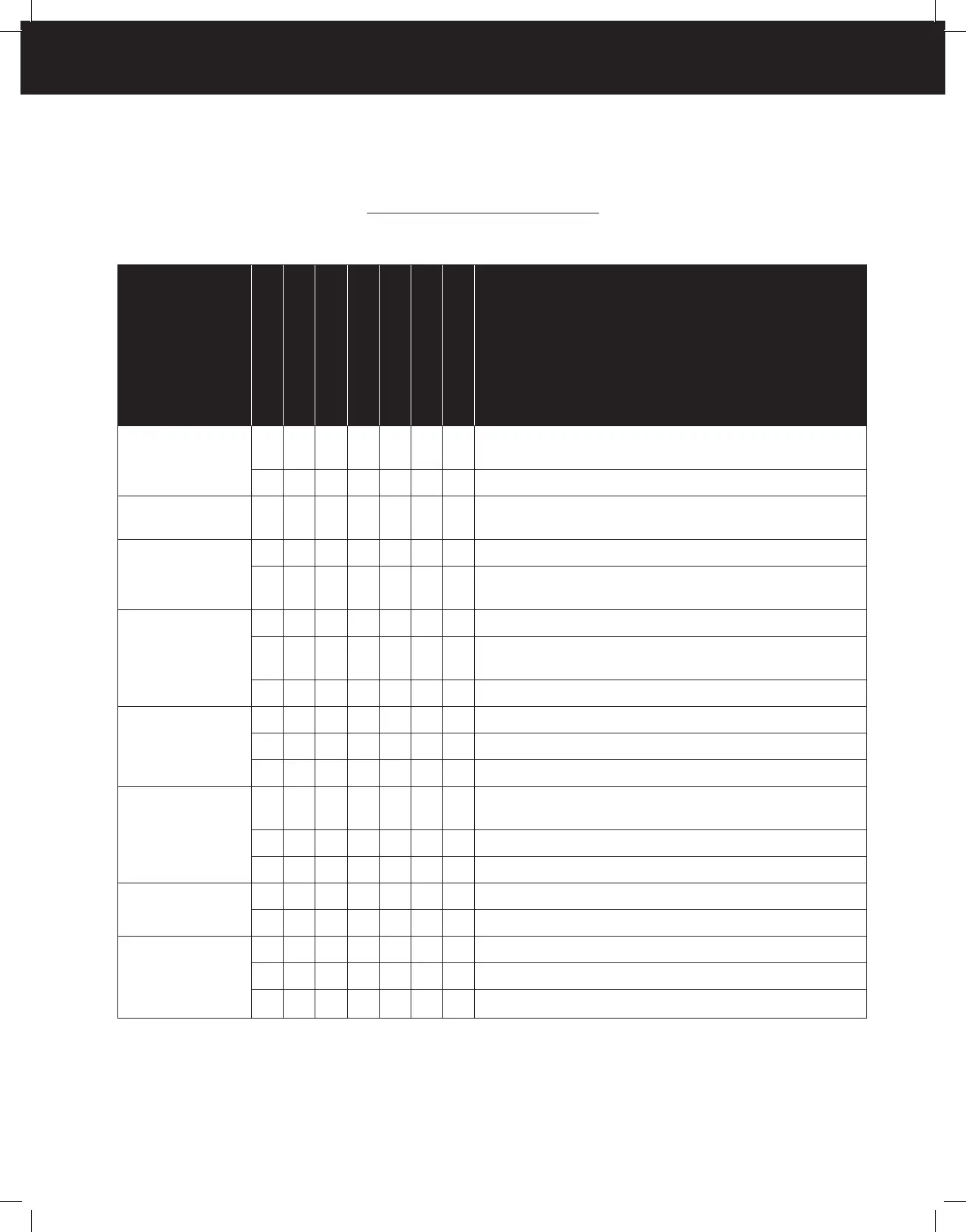

155

Maintenance

Item

Procedure to be performed

Maintenance schedules are minimum requirements. Ex-

tended use, extreme temperatures, high humidity or other

extreme conditions will require more frequent mainte-

nance.

Frame &

Underbelly

● ●

Check for damage, loose wires and debris. Clean as neces-

sary.

● ●

Check frame for rust and touch up as necessary.

Hitch/Coupler

● ●

Chekc for damage and wear. Clean and lubricate (with

grease).

LP System

●

Have systems tested for leaks by qualified dealer.

●

Have pressure and reguator settings checked by qualified

dealer.

Plumbing System

● ● ●

Check hoses, fittings and pipes for leaks. Tighten as required.

● ●

Lubricate termination valve cables (WD-40 or lithium

grease).

●

Winterize system (cold weather locations).

Roof & Roof

Attachments

● ●

Inspect voids, gaps and cracks. Reseal as necessary.

● ●

Clean roof with water and mild detergent.

● ●

Clean and lube roof vent mechanisms with light oil.

Safety Equipment

● ● ●

Check operation of detectors. Remove and repace batteries

every 6 months if equipped.

● ●

Test and check fire extinguishers for proper charge.

● ● ●

Test and confirm egress (exit) windows function properly.

Slide Rooms

●

Check slide roof for debris and clear.

● ● ●

Check and clean all seals.

Wheels & Tires

● ● ●

Check wheels for proper lug torque.

● ●

Inspect tires for wear and damage.

● ● ●

Check for proper tire infation.

Every Trip

Annually

Monthly

Before/After Storage

Every 3 Months

As Required

Every 6 months

REQUIRED MAINTENANCE SCHEDULE

MAINTENANCE

Loading...

Loading...