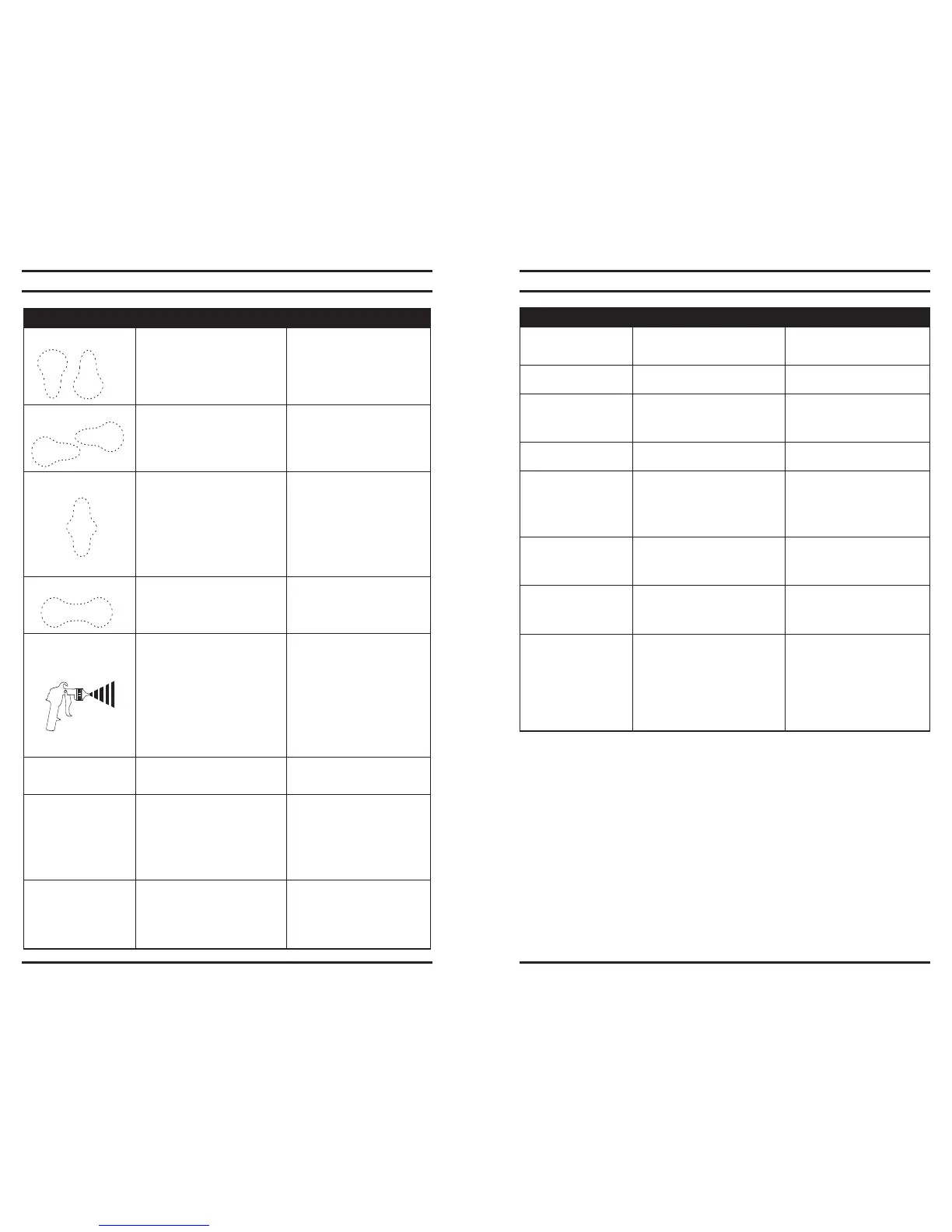

Problem Encountered Possible Cause Corrective Action

Excessive overspray Gun too far from work surface. Adjust to proper distance.

Improper stroking Move at moderate pace, parallel to

(arcing, gun motion too fast). work surface.

Excessive fog Too much, or too fast-drying thinner. Remix properly.

Too much atomization air pressure. Reduce pressure.

Dry spray Air pressure too high. Reduce air pressure.

Gun tip too far from work surface. Adjust to proper distance.

Gun motion too fast. Slow down.

Gun out of adjustment. Adjust.

Fluid leaking from packing nut Packing nut loose. Tighten, do not bind needle.

Packing worn or dry. Replace or lubricate.

Fluid leaking or dripping from Packing nut too tight. Adjust.

front of pressure feed gun Dry packing. Lubricate.

Fluid tip or needle worn or damaged. Replace tip.

Foreign matter in tip. Clean.

Fluid needle spring broken. Replace.

Wrong size needle or tip. Replace.

Runs and sags Too much material flow. Adjust gun or reduce fluid pressure.

Material too thin. Mix properly or apply light coats.

Gun tilted on an angle, or gun motion Hold gun at right angle to work and adapt

too slow. to proper gun technique.

Thin, sandy coarse finish Gun too far from surface. Check distance. Normally about 8”.

drying before it flows out Too much air pressure. Reduce pressure and check spray pattern.

Improper thinner being used. Follow paint manufacturer’s

mixing instructions.

Thick, dimpled finish Gun too close to surface. Check distance. Normally about 8”.

“orange peel” Too much material coarsely atomized. Increase air pressure or reduce

fluid pressure.

Air pressure too low. Increase air pressure or reduce

fluid pressure.

Improper thinner being used. Follow paint manufacturer’s

mixing instructions.

Material not properly mixed. Follow paint manufacturer’s instructions.

Surface rough, oily, dirty. Properly clean and prepare surface.

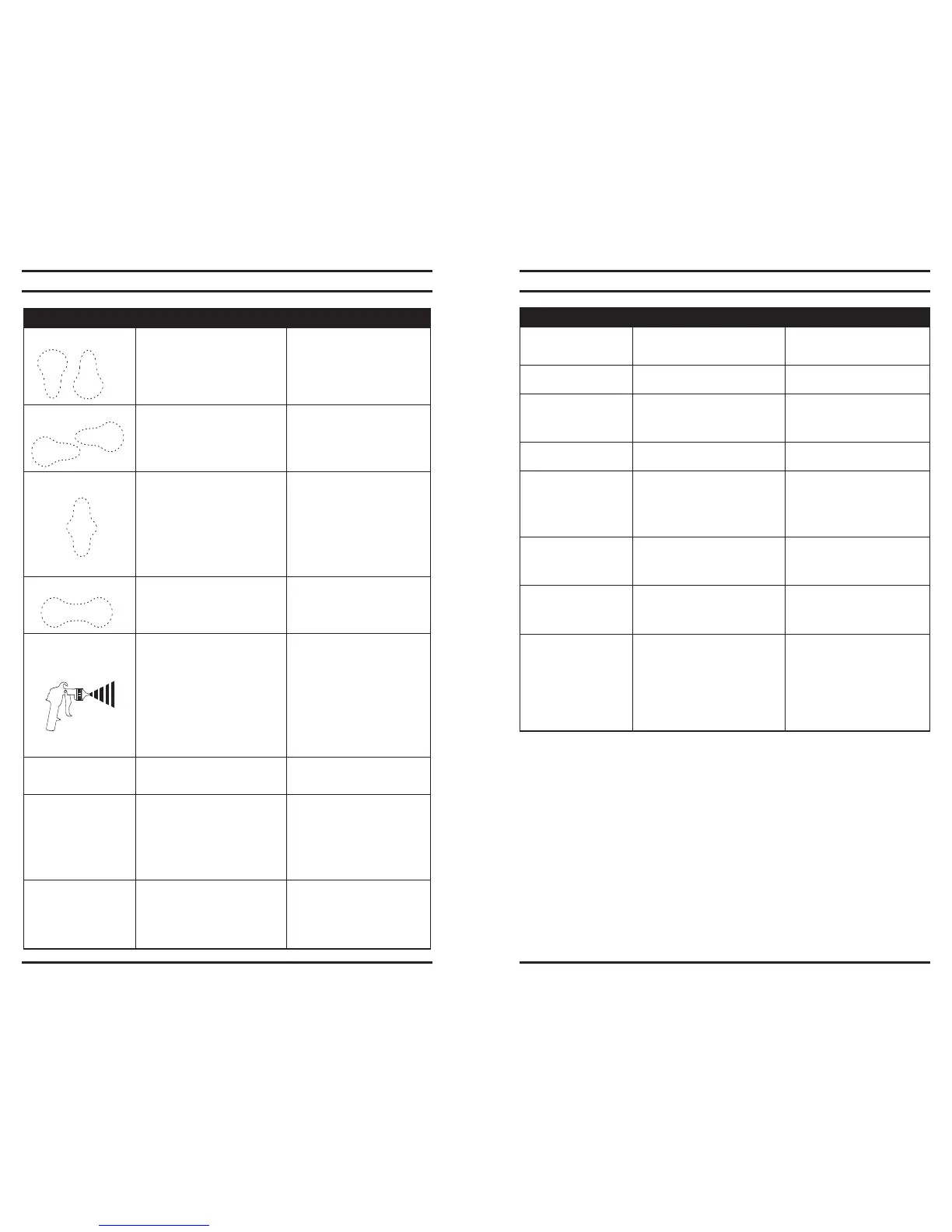

Problem Encountered Possible Cause Corrective Action

Heavy top or bottom pattern. Horn holes plugged. Clean. Ream with non-metallic point.

Obstruction on top or bottom of fluid tip. Clean.

Cap and/or tip seat dirty. Clean.

H

eavy right or left side pattern. Left or right side horn holes plugged. Clean Ream with non-metallic point.

Dirt on left or right side of fluid tip. Clean.

Heavy center pattern. Fluid pressure too high for atomization air Balance air and fluid pressure.

(pressure feed).

Material flow exceeds air cap’s capacity. Increase spray pattern width with

spreader adjustment valve.

Thin or lower fluid flow.

Spreader adjustment valve set too low. Adjust.

Increase pressure.

Material too thick. Thin to proper consistency.

Split spray pattern. Atomization air pressure too high. Reduce at regulator or gun.

Fluid pressure too low (pressure feed only). Increase fluid pressure

(increases gun handling speed).

Spreader adjusting valve set too high. Adjust.

Spitting or pulsating spray. Loose or damaged fluid tip/seat. Tighten or replace.

May also be accompanied by

bubbling in the paint cup. Material level too low. Refill.

Container tipped too far. Hold more upright.

Obstruction in fluid passage. Back flush with solvent.

Loose or broken fluid tube or Tighten or replace.

fluid inlet nipple.

Dry, loose or worn needle packing. Replace packing.

Unable to get round spray. Spreader adjustment screw not Clean or replace.

seating properly.

Air cap retaining ring loose. Tighten.

Will not spray. No air pressure at gun. Check air supply and air lines.

Internal mix or pressure feed air cap and Change to proper suction feed air cap

tip used with suction feed. and tip.

Fluid pressure too low with internal mix Increase fluid pressure at tank.

cap and pressure tank.

Fluid needle adjusting screw not open Open fluid needle adjusting screw.

enough.

Fluid tool heavy for suction feed. Thin material or change to pressure feed.

Starved spray pattern. Inadequate material flow. Back fluid adjusting screw out to first

thread or increase fluid pressure at tank.

Low atomization air pressure (suction feed). Increase air pressure and rebalance gun.

Too much atomization air pressure. Reduce pressure.

Loading...

Loading...