10

All drum motors are factory filled with oil that is free of detergent additives.

NOTE: Do not use oil additives which can cause damage to the motor

insulation or seals. Electrically conductive-bases oils, such as graphite and

molybdenum disulfide, should not be used, as they will result in electric

motor insulation damage.

OIL CHANGE

1. Allow the drum motor to cool to normal temperature.

2. Rotate the drum motor until the oil plug is located in the 6 o’clock position.

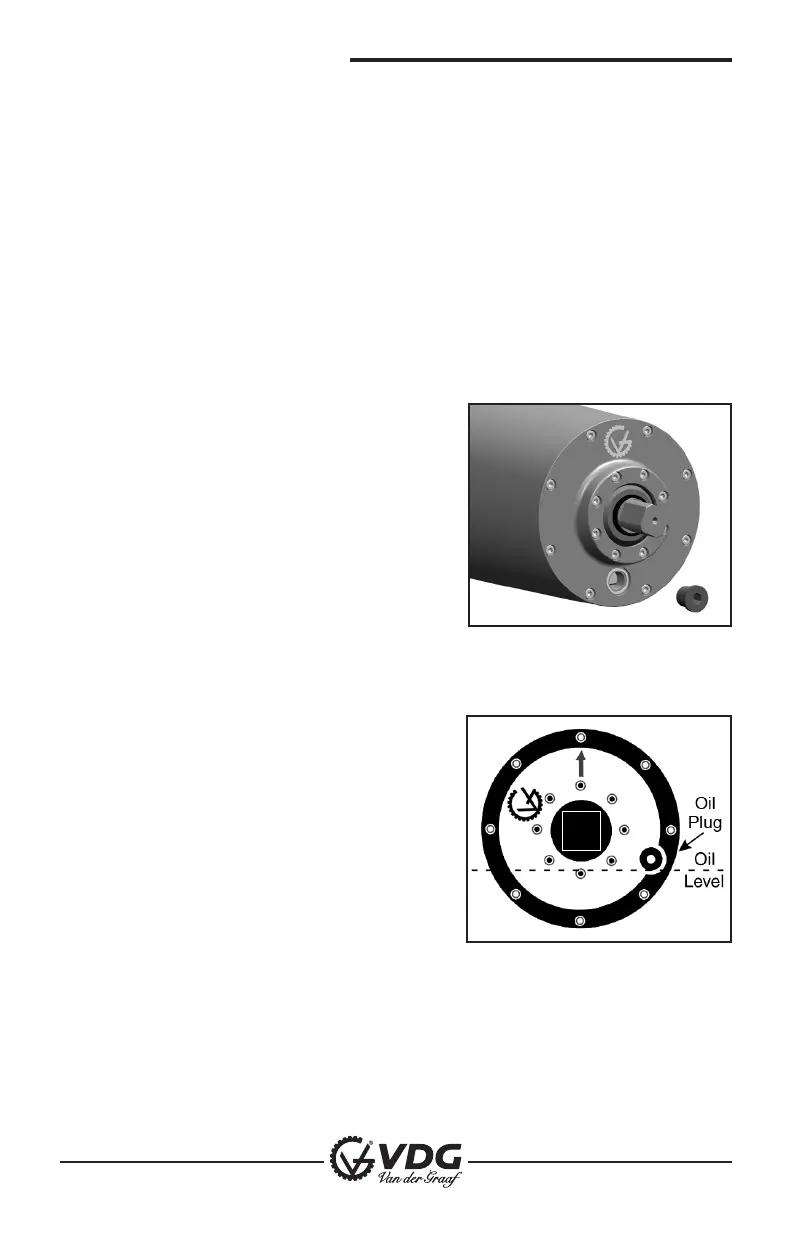

3. Unscrew the oil plug and allow the oil

to drain completely.

Note: There may be internal pressure

released when removing the oil plug,

this is normal.

4. Refill the drum motor with the suggested

oil type (page 11) and amount of oil

(pages 12-13).

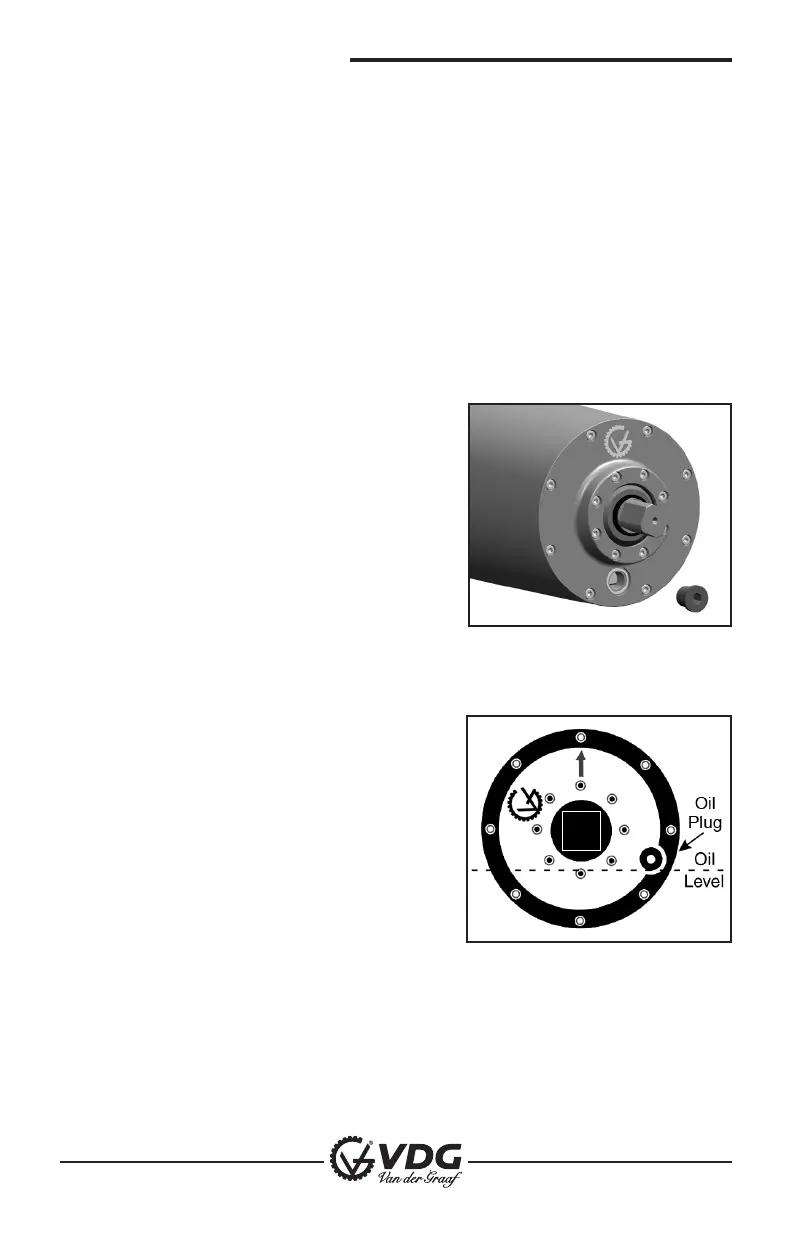

To verify the oil level, rotate the drum motor until the oil plug is in the

4 o’clock position as shown in the diagram. The minimum oil level

should be up to the level of the oil plug.

For exact oil quantities consult VDG

(Van der Graaf) Technical Support*.

Note:

typical levels are higher but should

not exceed the level where the oil plug

is in the 3 o’clock position.

5. Re-install the oil plug and if available,

install a new copper seal.

*VDG (Van der Graaf) Technical Support:

1 (866) 595-3292 or email: service@vandergraaf.com

Oil Change Instructions

Loading...

Loading...