2

Installation Instructions

INSTALLING THE DRUM MOTOR:

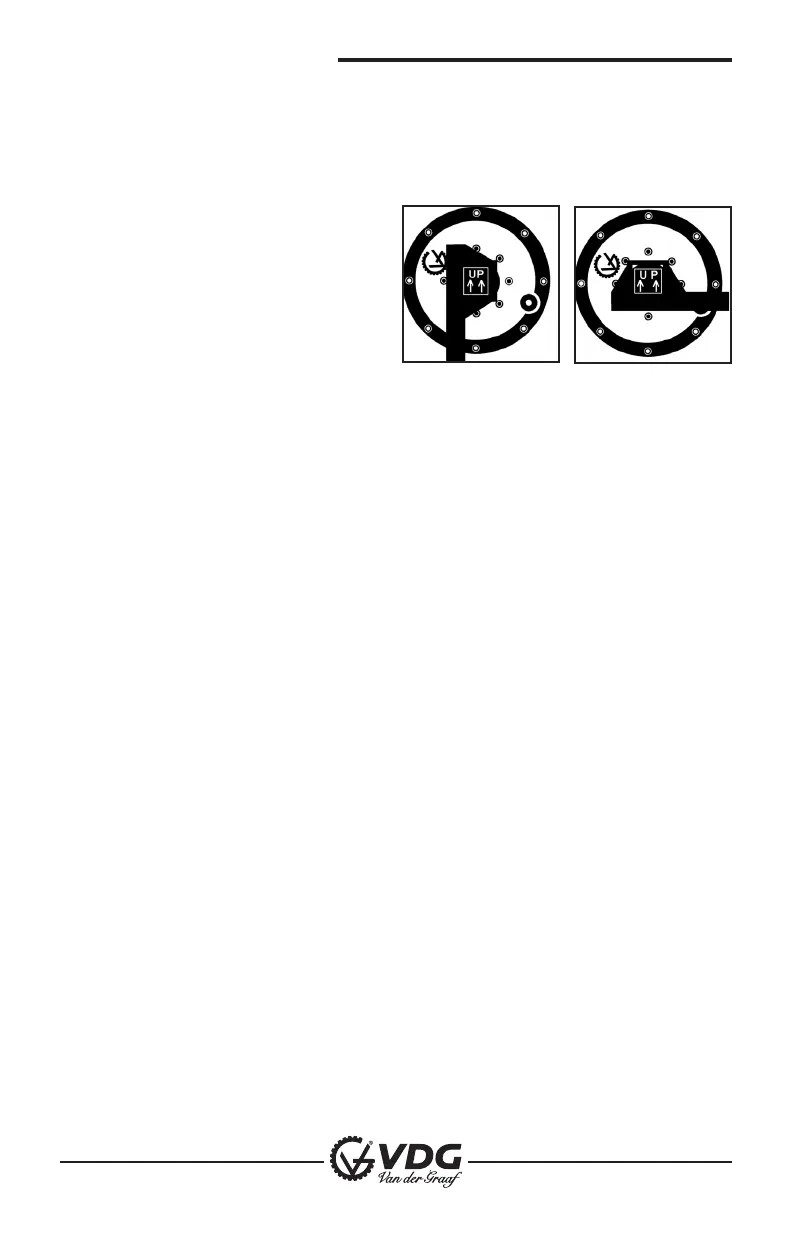

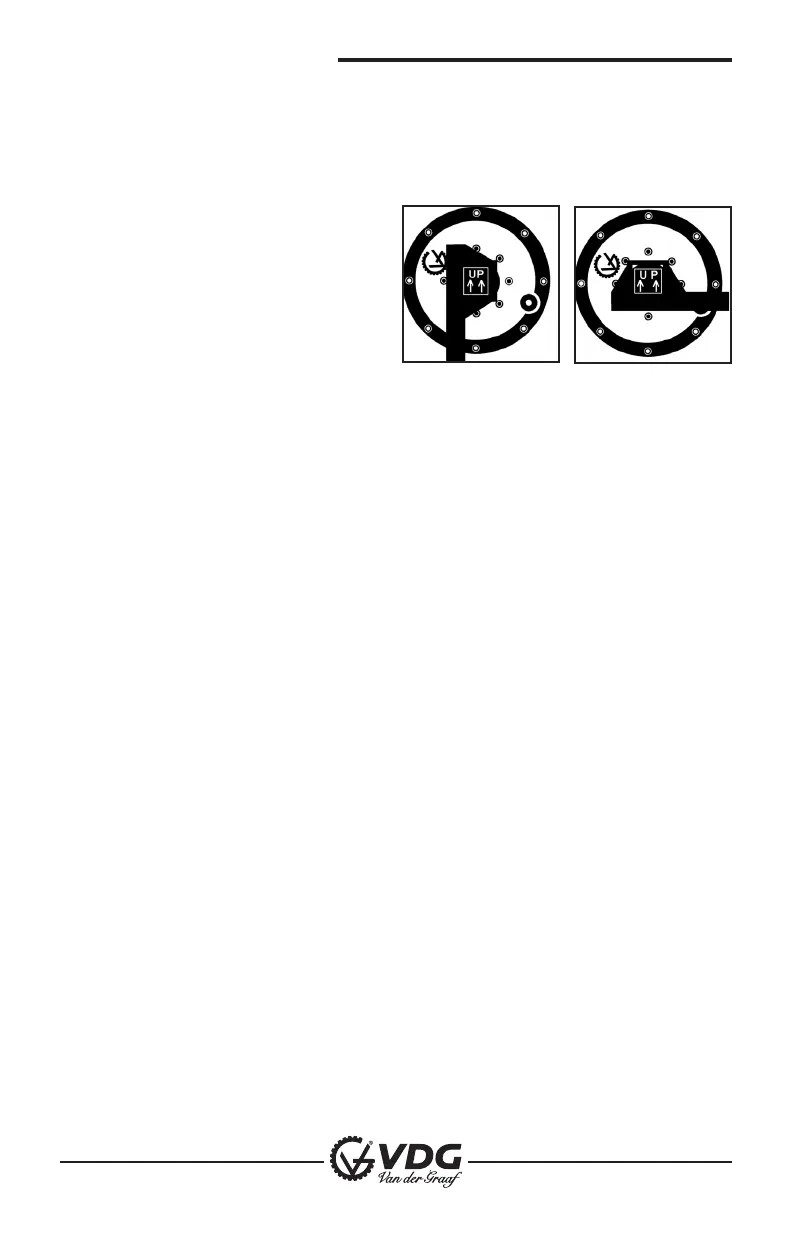

The Drum Motor MUST be mounted horizontally, square to the conveyor

frame and parallel to the idler pulley. The arrow on the shaft opposite the

junction box MUST be pointing up,

with no more than 30 degrees off

of vertical. This will ensure that the

gear reducer is properly lubricated.

For special mounting arrangements,

consult your Van der Graaf (VDG)

representative.

NOTE: The Drum Motor has been factory filled with the correct amount

and type of oil, and does not require any additional oil.

ELECTRICAL CONNECTION:

To ensure proper electrical connection, always reference the connection

diagrams provided (see pages 4-8). Be sure to use qualified personnel and

observe compliance with local electrical codes. If in doubt, consult your

Van der Graaf representative. Ensure that the motor is being installed with

the appropriate overload protection device(s), (fuse, breakers, thermal

overload protection {GV-THERM}) if equipped. Reference the Drum Motor

nameplate to determine allowable full load amperage.

When the motor is equipped with a backstop (TB) device, the motor must

be connected electrically according to the correct rotational direction (see

page 9 for complete instructions).

PRIOR TO STARTING:

1. Be sure that the Drum Motor is correctly connected and supplied with

the rated voltage.

2. Check that the Drum Motor and conveyor belt are unobstructed and

free to rotate.

CAUTION: Never over tension the conveyor belt as internal damage

may occur.

Loading...

Loading...