8

ISD Alarm Message Diagnostics

ISD VAPOR LEAKAGE

A Vapor Leakage Detection test failure occurs when the vapor recovery containment system leaks at 2 times the

allowable CARB standard defined in the TP-201.3. For a typical 12-hose site, that means it exceeds 8.5cfh (limit

ranges over 8-10 cfh for <6 to >24 hoses).

ISD MONITORING CATEGORY

Vapor Containment Monitoring as implemented by over-pressurization and Vapor Leakage Detection tests, is

responsible for ensuring that UST ullage pressure and system leak rate stay within regulatory boundaries. The

Vapor Leakage Detection test will check all components for leaks including: P/V valves, dispenser piping, vacuum

assist motors, nozzles, hoses, breakaways, vapor processor piping and elements as well as any other piping and

fitting or component connected into the UST ullage space.

DIAGNOSTIC PROCEDURE

• Run a TP 201.3 test and use common field techniques for determining the source of the containment system

leak.

• Fix all FLOW COLLECT alarms in a balance site first prior to diagnosing this alarm.

COMMON CAUSES

1. Tank Setup: Thermal coefficients on the gasoline tanks are in the correct range greater than or equal to

0.00060 and less than or equal to 0.00079. (Typically gasoline coefficients are programmed to 0.000700).

2. Phase I equipment, including but not limited to: dry breaks, spill buckets, tank inventory gauge caps, P/V

valves, fill caps.

3. Phase II equipment, including but not limited to: breakaways, hoses, nozzles, whips, vacuum assist motors,

solenoid valves, vapor shear valves.

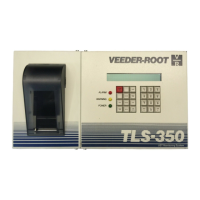

Refer to the Clear Test Repair Menu (on page 36) for clearing this alarm on the TLS after repairs are complete.

Loading...

Loading...