OPERATING PROCEDURES | TIRES & WHEELS

The general recommended tire ination pressure is 20 psi,

but the tire ination pressure can be changed according

to the specic terrain condition.

All four tires must have the same pressure for the best

control qualities. Always put the valve stem cap back after

checking or inate the tires.

Use a tire plug to repair small holes in the thread part of the

tires. For large holes or cuts, replace the whole tire.

▪ With the valve stem to the outside of wheel, install the

wheel & tire on the hub with lug nuts.

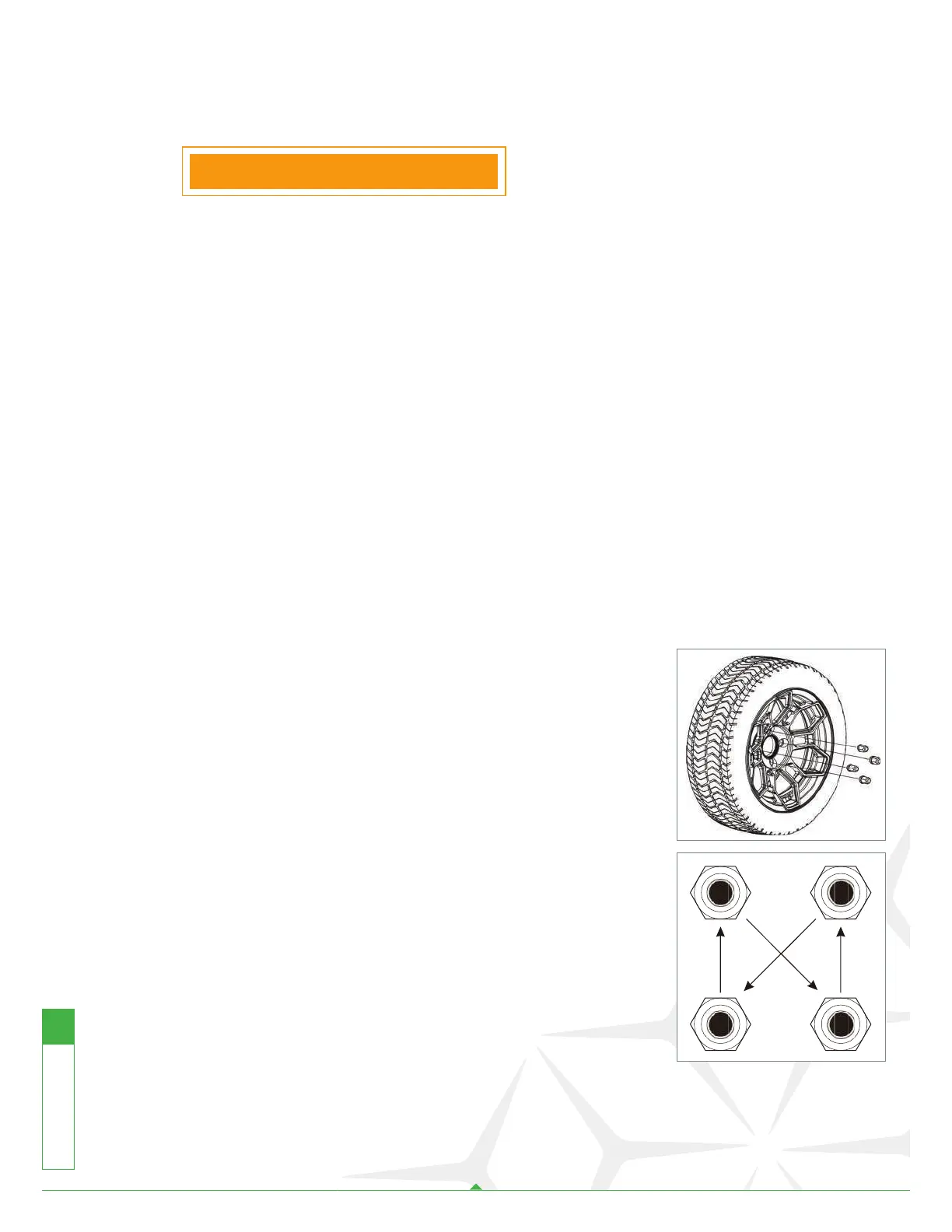

▪ Tighten the lug nuts with your fingers in the cross

sequence patten as shown.

▪ Tighten the lug nuts to 65 ft.lbs torque.

▪ Continue to follow the cross sequence pattern until the

correct torque is reached.

Tires & Wheels

DO NOT OVER INFLATE THE TIRES. EXCESS PRESSURE CAN CAUSE THE TIRE TO

EXPLODE.

TO DECREASE THE RISK OF TIRE EXPLOSION, ADD SMALL AMOUNTS OF AIR TO

THE TIRE AT INTERVALS TO SEAT THE TIRE BEADS.

OVER INFLATION OF SMALL TIRES CAN OCCURS IN A FEW SECONDS.

PROTECT FACE AND EYES WHEN REMOVING THE TIRE VALVE CORE.

USE ONLY SOCKETS MADE FOR IMPACT WRENCHES TO DECREASE THE RISK OF

INJURY CAUSED BY A BROKEN SOCKET.

DO NOT USE TIRES THAT HAVE INFLATION PRESSURE LESS THAN THE TIRE

PRESSURE RECOMMENDED.

ALWAYS FOLLOW THE CROSS-SEQUENCE PATTERN WHEN YOU INSTALL THE LUG

NUTS TO MAKE SURE THE WHEEL IS EVENLY SEATED AGAINST THE HUB.

WARNING!

Z

[

19

VENOM-EV.COM Venom EV User Guide

Loading...

Loading...