SERVICE

Service - 24

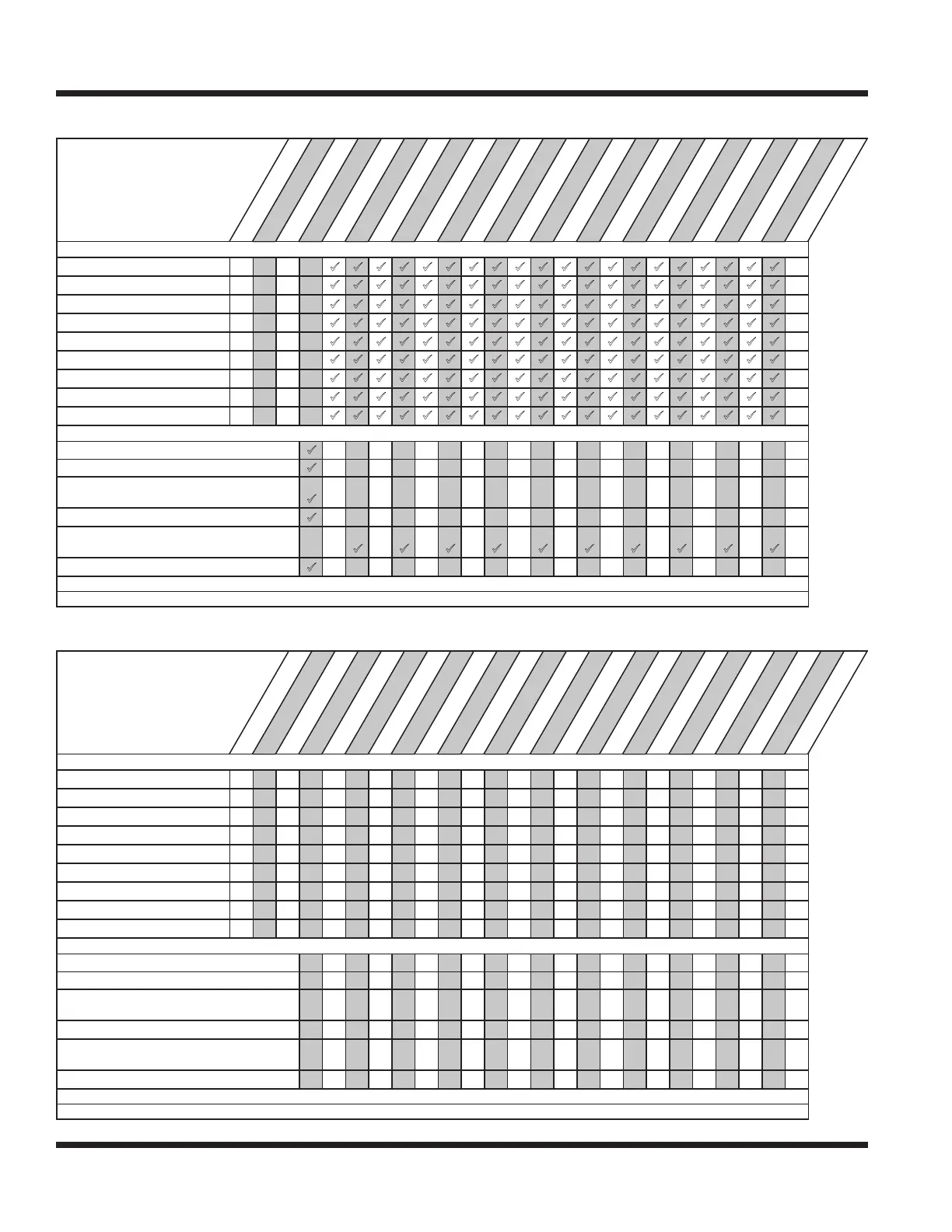

Maintenance Schedule

Maintenance

Schedule

#

of

L

oc

at

ions

#

o

f

P

um

ps

A

S

N

E

E

D

E

D

D

ai

ly

A

t

50

Ho

urs

A

t

100

H

our

s

A

t

150

H

ours

A

t

200

H

ours

A

t

250

H

ours

A

t

30

0

H

ours

A

t

350

H

ours

A

t

400

H

ours

A

t

450

H

ours

A

t

500

H

ours

A

t

550

H

ours

A

t

600

H

ours

A

t

650

H

our

s

A

t

700

H

ou

rs

A

t

750

H

ours

A

t

800

H

ours

A

t

850

H

ours

A

t

900

H

ours

A

t

950

H

ours

A

t

1000

H

ours

Y

ear

l

y

Caster Wheel Pivot

2 1

Wheel Axle Bearing

2 ^

**

Spindle

5 3

Hitch Arm Pivot

2 ^

Jackshaft Bearing

2 1

Rear Roller Bearing

2 1

Rear Rocker Pivot

2 ^

Hydraulic Flip-up Cylinder Ends

2 ^

Flip-up Rocker Bracket

1 ^

Inspect Safety Decals

Inspect belts and pulleys

Check Hitch Pivot Bolts.

Torque to 151 ft-lbs (205 Nm)

** Operation in severe conditions may require more frequent service intervals.

^ Grease Until Fresh Grease is visible

Inspect for Loose, Missing, or Worn Components

Inspect Mower Blades and Blade Retaining

Bolts. Torque to 75-80 ft-lbs (102-108 Nm)

Check Tire Pressure - 8-10 psi (55-69 kPa)

Grease & Lubrication: See Lubrication Section

Inspection

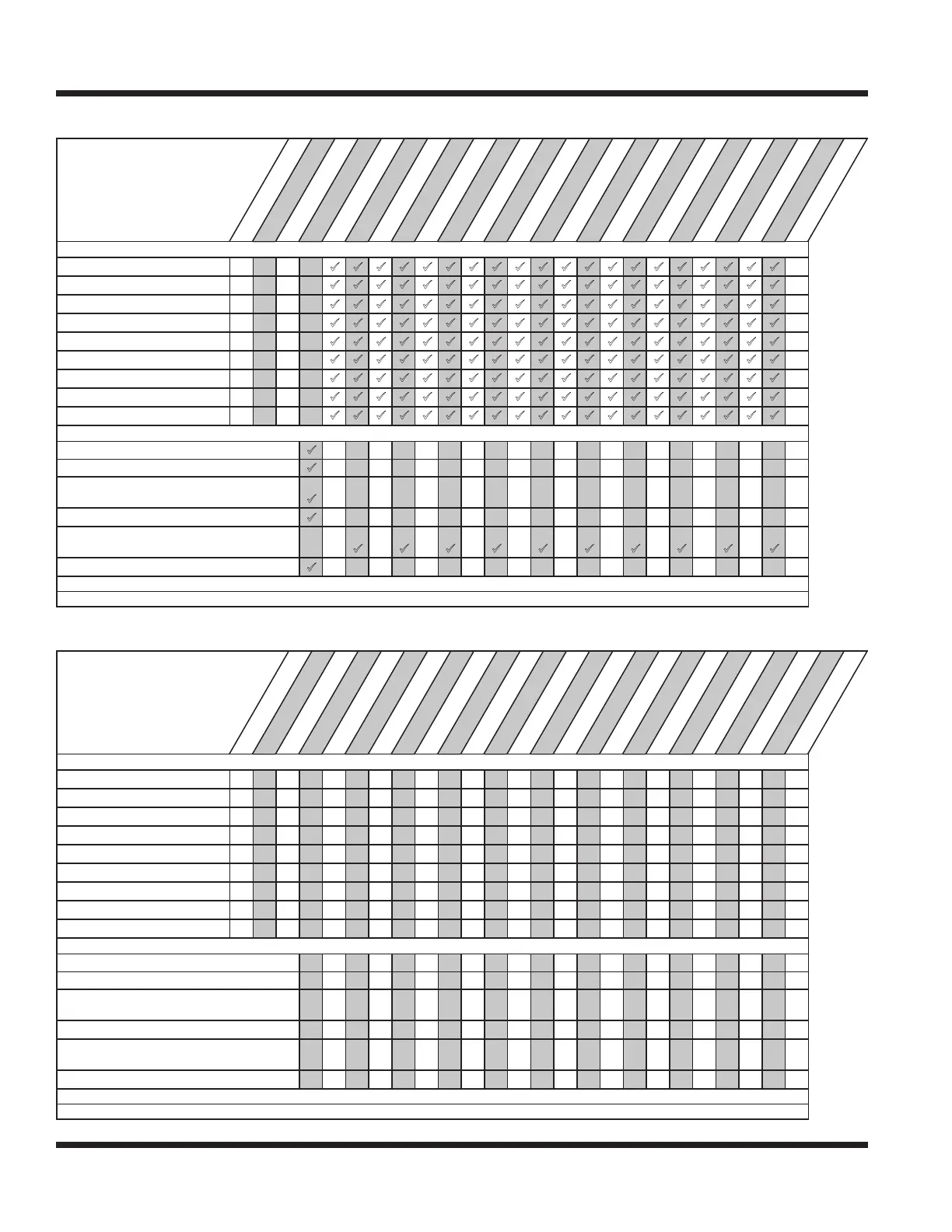

Maintenance Checklist

Maintenance

Checklist

#

of

L

oc

at

ions

#

o

f

P

um

ps

A

S

N

E

E

D

E

D

D

ai

ly

A

t

50

Ho

urs

A

t

100

H

our

s

A

t

150

H

ours

A

t

200

H

ours

A

t

250

H

ours

A

t

30

0

H

ours

A

t

350

H

ours

A

t

400

H

ours

A

t

450

H

ours

A

t

500

H

ours

A

t

550

H

ours

A

t

600

H

ours

A

t

650

H

our

s

A

t

700

H

ou

rs

A

t

750

H

ours

A

t

800

H

ours

A

t

850

H

ours

A

t

900

H

ours

A

t

950

H

ours

A

t

1000

H

ours

Y

ear

l

y

Wheel Swivel Bearing

2 1

Wheel Axle Bearing

2 ^

**

Spindle

5 3

Hitch Arm Pivot

2 ^

Jackshaft Bearing

2 1

Rear Roller Bearing

2 1

Rear Rocker Pivot

2 ^

Hydraulic Flip-up Cylinder Ends

2 ^

Flip-up Rocker Bracket

1 ^

Inspect Safety Decals

Inspect belts and pulleys

Check Hitch Pivot Bolts.

Torque to 151 ft-lbs (205 Nm)

** Operation in severe conditions may require more frequent service intervals.

^ Grease Until Fresh Grease is visible

Inspect for Loose, Missing, or Worn Components

Inspect Mower Blades and Blade Retaining

Bolts. Torque to 75-80 ft-lbs (102-108 Nm)

Check Tire Pressure - 8-10 psi (55-69 kPa)

Grease & Lubrication: See Lubrication Section

Inspection

Loading...

Loading...