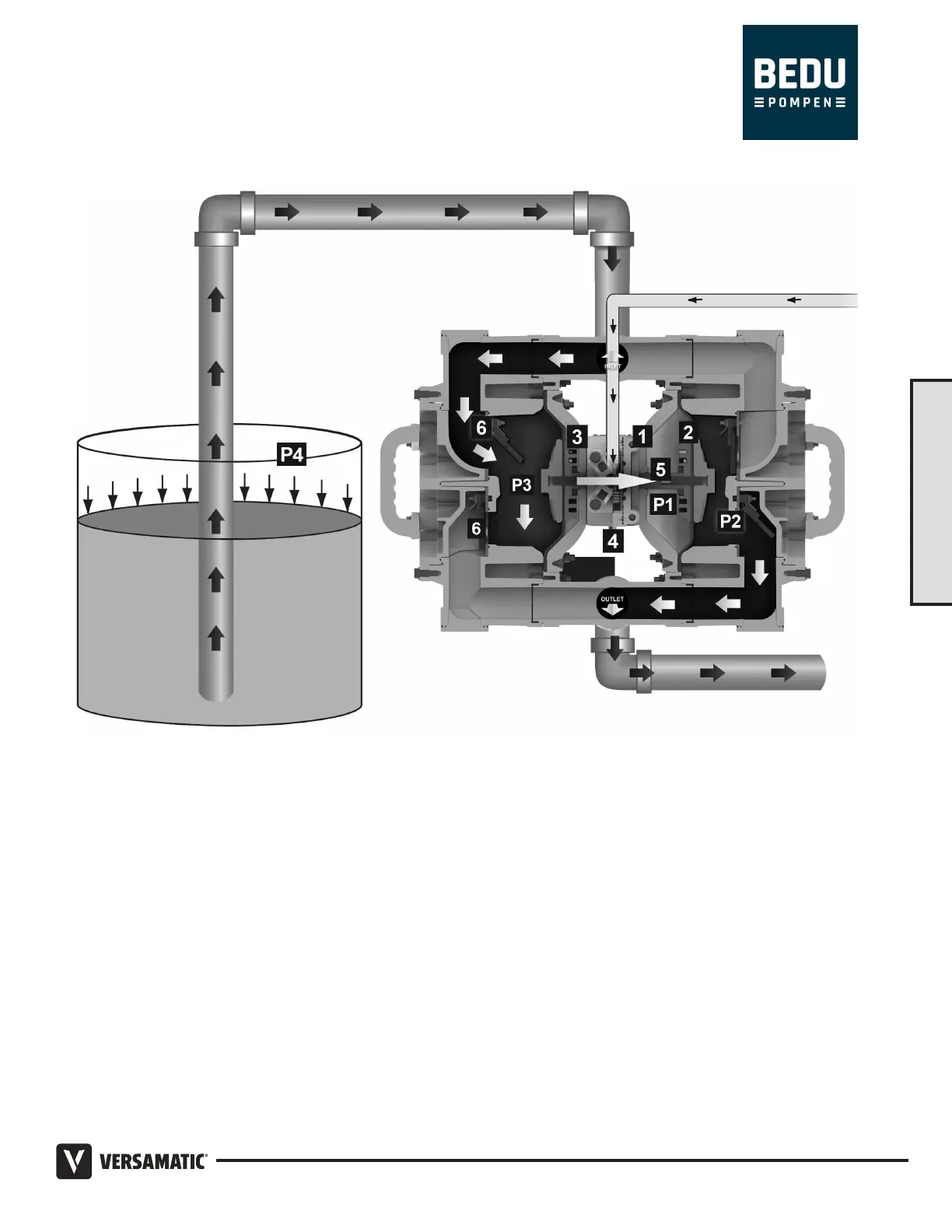

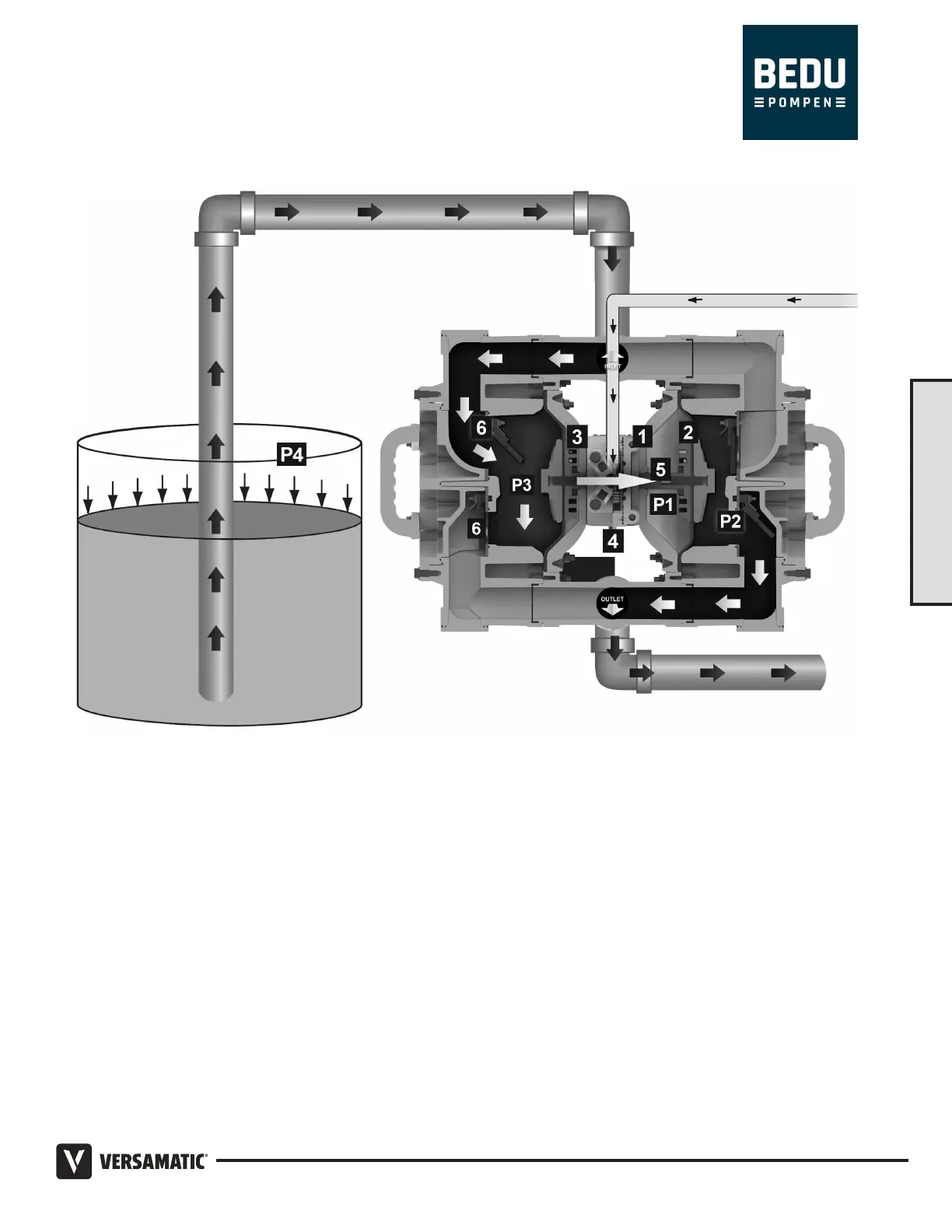

Air-Operated Double Diaphragm (AODD) pumps are powered by compressed

air or nitrogen.

The main directional (air) control valve

①

distributes compressed air to

an air chamber, exerting uniform pressure over the inner surface of the

diaphragm

②

. At the same time, the exhausting air

③

from behind the

opposite diaphragm is directed through the air valve assembly(s) to an

exhaust port

④

.

As inner chamber pressure

(P1) exceeds liquid chamber pressure (P2),

the rod

⑤

connected diaphragms shift together creating discharge on one

side and suction on the opposite side. The discharged and primed liquid’s

directions are controlled by the check valves (ball or ap)

⑥

orientation.

The pump primes as a result of the suction stroke. The suction stroke lowers

the chamber pressure

(P3) increasing the chamber volume. This results in

a pressure differential necessary for atmospheric pressure

(P4) to push the

uid through the suction piping and across the suction side check valve and

into the outer uid chamber

⑦

.

Suction (side) stroking also initiates the reciprocating (shifting, stroking

or cycling) action of the pump. The suction diaphragm’s movement is

mechanically pulled through its stroke. The diaphragm’s inner plate makes

contact with an actuator plunger aligned to shift the pilot signaling valve.

Once actuated, the pilot valve sends a pressure signal to the opposite end

of the main directional air valve, redirecting the compressed air to the

opposite inner chamber.

Principle of Pump Operation

MODEL SPECIFIC

Model E2 Bolted Plastic Flap • 7

Loading...

Loading...