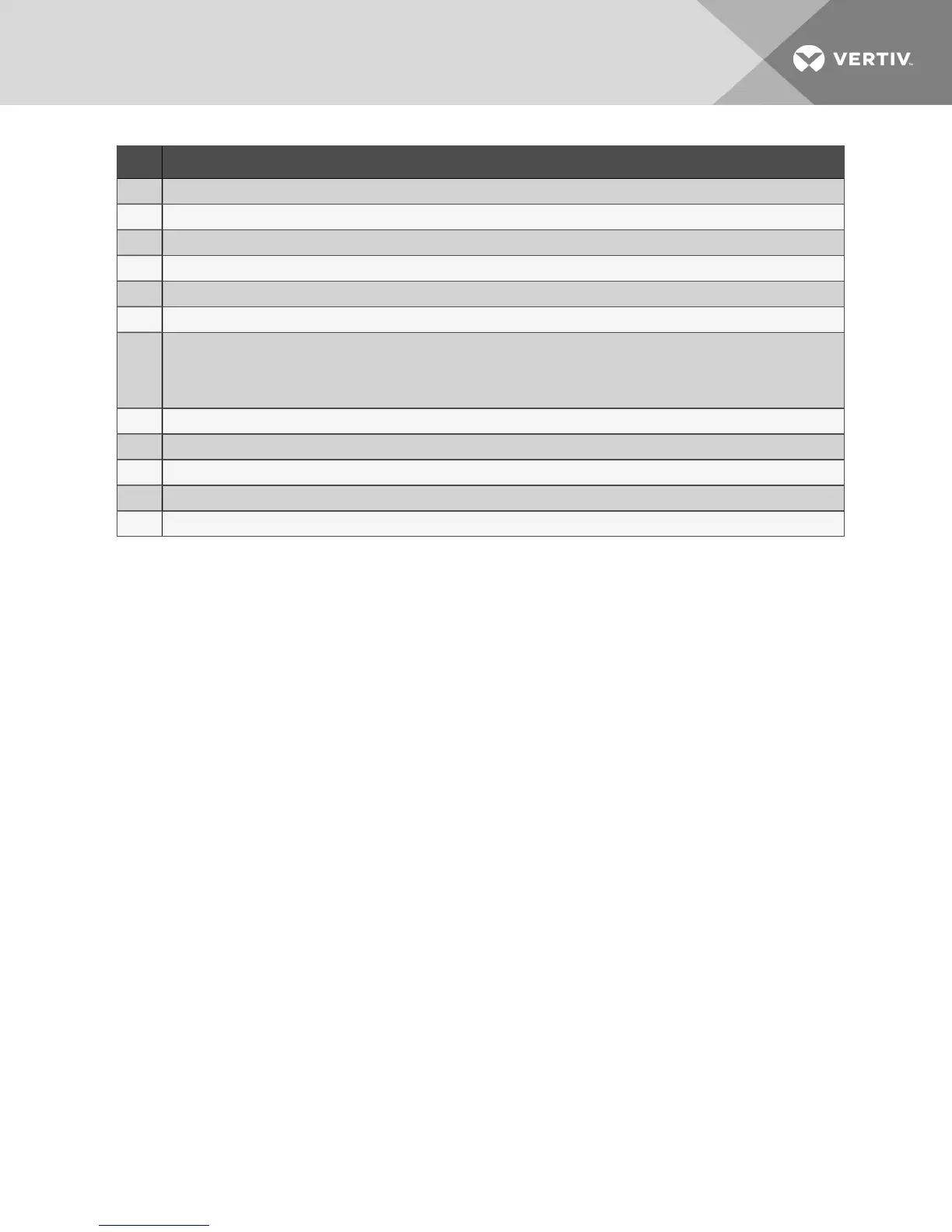

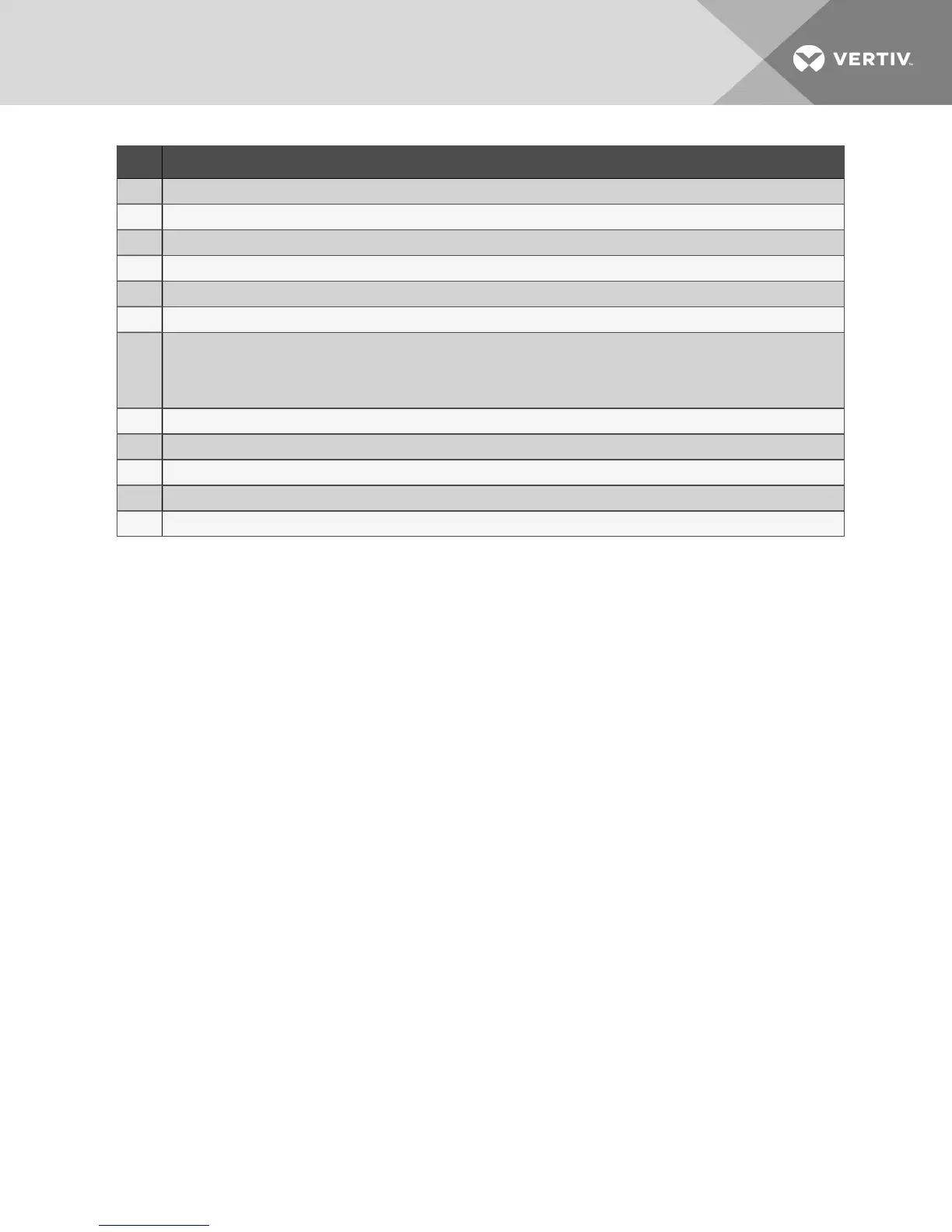

Item Description

14 Check valve

15 Pressure-balancing valve

16 Sight glass

17 Pressure-relief valve

18 Lee-Temp receiver

19 Receiver-heater pressure-limiting switch

20

Schrader port with valve core

NOTE: The system includes a factory-installed Schrader valve with core in the liquid line downstream of the

receiver. Proper evacuation of the condenser side of the system can be accomplished only using the downstream

Schrader valve. See the appropriate piping schematic for your system in Submittal Drawings on page35.

21 Liquid-line solenoid valve

22 Liquid line

23 Filter drier

24 Expansion valve

25 Evaporator coil

To evacuate and leak-test the system:

1. Open the liquid-line solenoid valve by removing the holding coil, and apply a solenoid-valve

service magnet to the valve.

2. Connect manifold-gauge hoses on the discharge- and suction-line Schrader ports, open the

service valves, and place a 150PSIG(1034kPa)charge of dry nitrogen with a tracer of

refrigerant, then check the system for leaks with a suitable leak detector.

3. After completion of leak testing, release the test pressure, (observe local code) and pull an

initial deep vacuum of 500microns on the system with a suitable pump.

4. After 4hours, check the pressure readings and, if they have not changed, break vacuum with

dry nitrogen. Pull a second and third vacuum to 500 microns or less. Re-check the pressure

after 2hours.

When the 3 checks are complete, proceed to Charging Air-cooled Systems below.

Charging Air-cooled Systems

NOTICE

Risk of improper refrigerant charging. Can cause equipment damage.

R-410A is a blended refrigerant and must be introduced and charged from the cylinder only as

a liquid.

When adding liquid refrigerant to an operating system, it may be necessary to add the

refrigerant through the valve in the compressor suction line. Care must be exercised to avoid

damage to the compressor. We recommend connecting a sight glass between the charging

hose and the compressor suction service valve. This will permit adjustment of the cylinder

hand valve so that liquid can leave the cylinder while allowing vapor to enter the compressor.

NOTICE

Risk of improper component re-installation. Can cause equipment damage.

Identify and mark location of the discharge pressure switch. It must be reinstalled in its original

location.

Initially charging the system:

1. Check the nameplate on the indoor unit for refrigerant type to use.

4 Piping and Refrigerant Requirements 17

Loading...

Loading...