Failure to install the machine within recommended limits will result in poor

performance of this system

CAUTION: After receiving the machine from logistics company, the machine need to be

placed steady for 6 hours to make sure the compressors work normally.

1.Uncrate the machine.

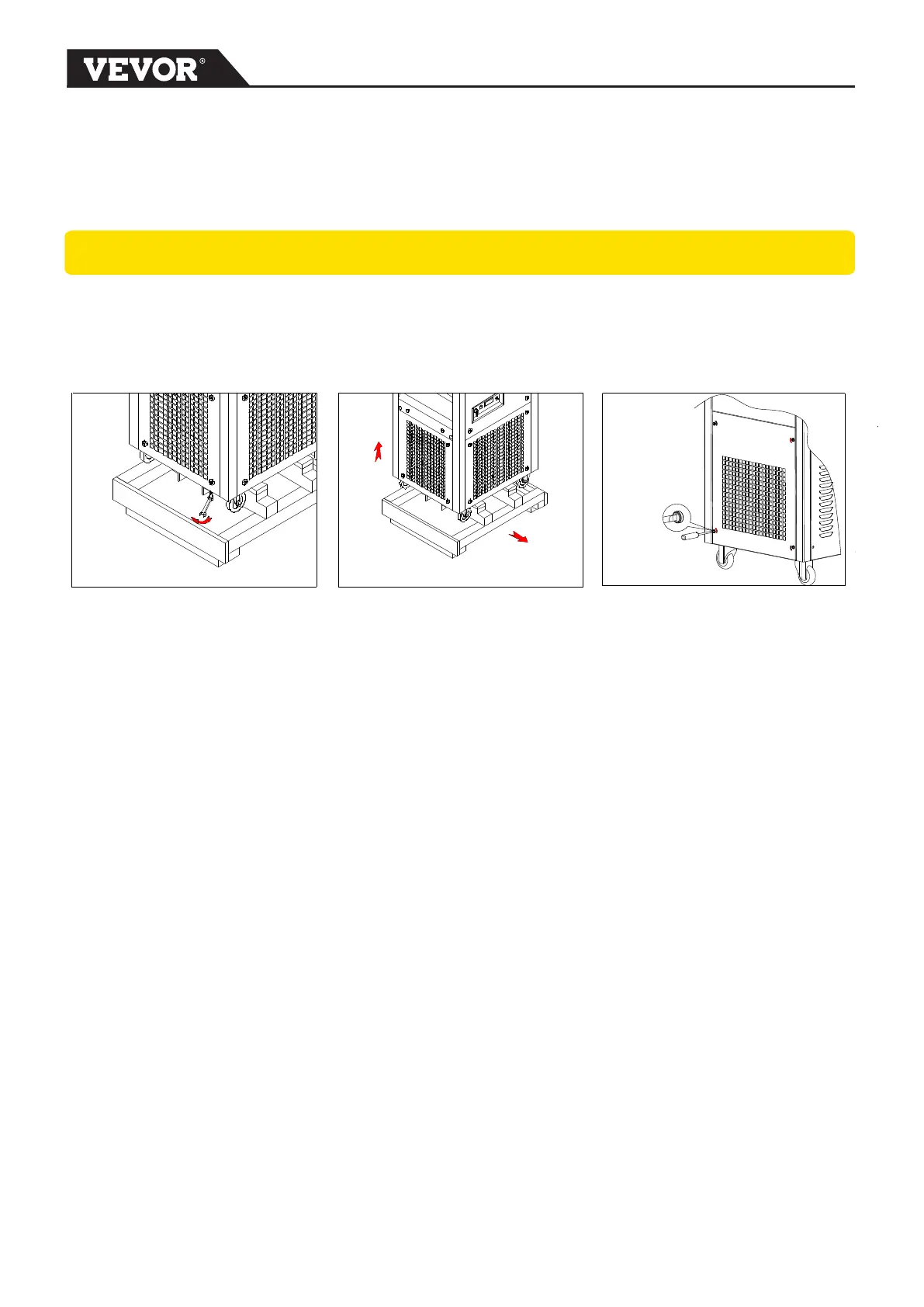

2.Remove 4 nuts holding the machine to the pedestal (Figure 1-1).

3.Raise the machine, then draw out the pallet (Figure 1-2).

Figure 1-1 Figure 1-2

Check the machine’s back panel of the nameplate .Make sure the working power fit

the machine. The unit must be connected to a properly grounded receptacle.

This machine is air cooling unit ,which require a minimum of 200mm of clearance

around both sides.

Keeping the working place dry and clean .Pay attention the insect and mice ,don’t

let them go inside of machine to destroy the wires and other parts.

After the installation press the wheel brake to make sure the machine in the fixed

position

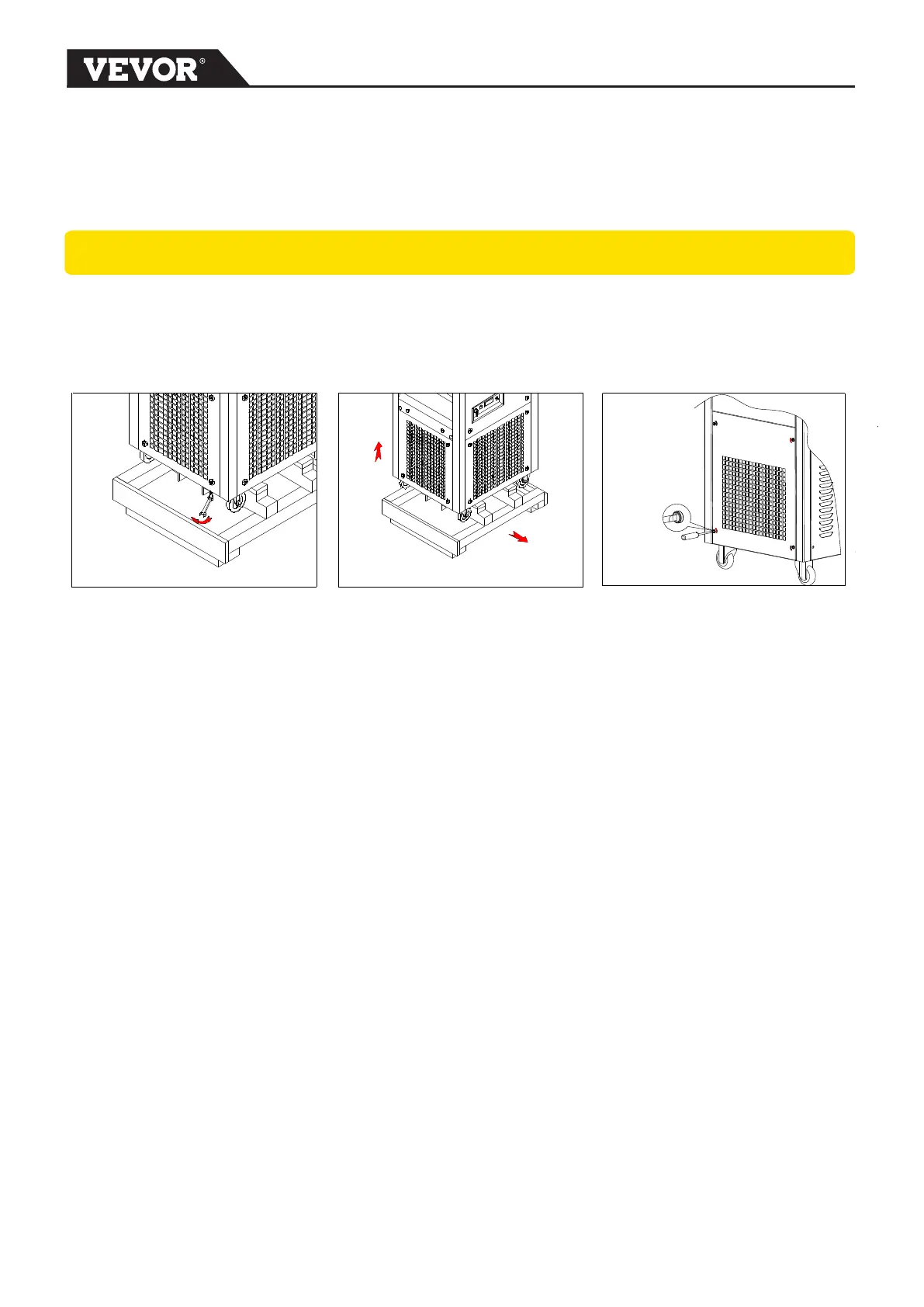

Open the back panels(Figure 1-3) .Make sure all the components are not loose

during transport .Such as motor ,motor belt , compressor and so on

(NOTE: The maximum gradient that is allowed is 15 degree during movement )

D.

E .

F .

G.

H.

Figure 1-3

The machine you have purchased has been carefully engineered and manufactured to give

you dependable operation.

The VEVOR Model SS240 is highly sophisticated pieces of equipment, when properly

operated and cared for, will produce a consistent quality product. Like all mechanical

products, they will require cleaning and maintenance. A minimum amount of care and

attention is necessary if operating procedures outlined in this manual are followed

closely.

This Operator’s Manual should be read before operating or performing any maintenance

on your equipment.

2

Loading...

Loading...