25

Gasifying boiler VIGAS

15.5 SECONDARY AIR FLAPS POSITION SET-UP

15.6 LAMBDA SENSOR AND EXHAUST GAS THERMOMETER

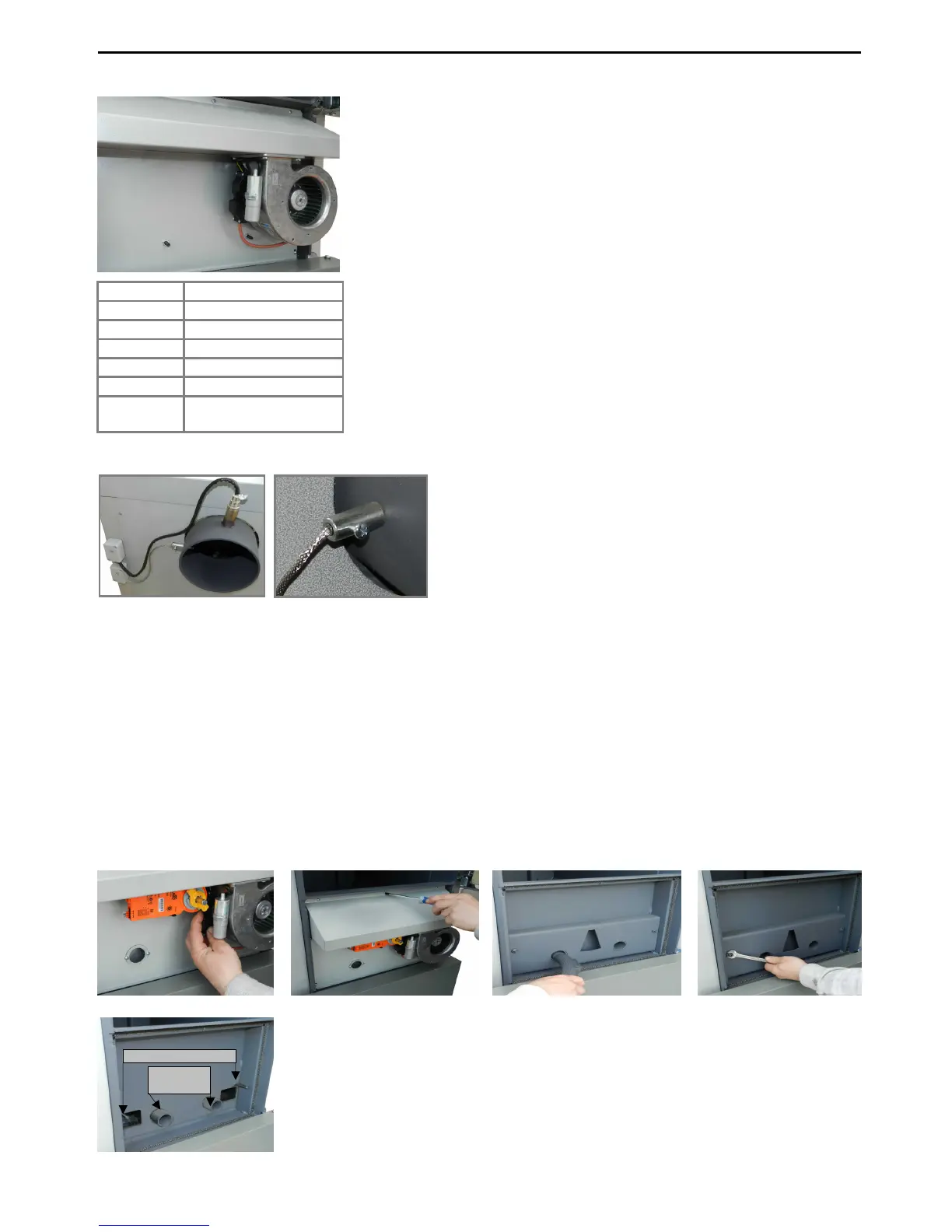

15.7 SECONDARY AIR SYSTEM CLEANING

Secondary airway cleaning

During cleaning disconnect the boiler from the power supply!

Step 1: Unplug fan and flap servo-unit connectors

Step 2: Under the fan plate romoval (see chap 15.4 for assembly)

Step 3: Vacuum out the secondary air pipes and check if it is clean.

Cleaning the boiler’s pipe airway system is necessary to achieve optimum burning. If sawdust is used as

fuel often, the airway must be cleaned at least once in the season. The system is built with primary and

secondary air trunks. The boiler co

nstruction disassembly of parts to enable areas to be cleaned. When

the fan cover is removed (8) pic.3 this allows ccess to the fan. To clean the pipe airway system

following steps:

Step 1.

Step 2. Step 3. Step 4.

Step 5.

secondary

air

primary air

The position o

f the secondary air flaps can considerably affect burning

quality. VIGAS

Lambda Control

boilers control the amount of secondary air

automatically. This option provides optimum conditions for burning of

all wood types. In VIGAS boilers without lambda sensor the

of primary and secondary air can be adjusted by screws „1“.

Optimum adjustment of secondary air screws „1“ is 2,5 turns

factory set. To change or control position follow these steps:

Step 1: loosen the safety bolt nut on screw „1“,

Step 2: drive screw „1“ in towards boiler all the way

Step 3: then, adjust by 2,5 turn (optimum),

Step 4: tighten safety bolt nut.

Boilers without lambda sensor are equipped with a safety flap (above

the fan) „2“ which stops air going through the fa

the fan is stoppped (only chimney draught).

not have sufficient output, check the function of this.

0 Not recommended

1 Wet wood

1,5 Wet softwood

2 Dry softwood

2,5 Dry hardwood

2,5 + Very dry hardwood,

small chips

The Lambda sensor and exhaust gas thermometer must

be clean to function properly. When cleaning exchanger

always gently wipe away dust from the lambda sensor „1“

and exhaust gas thermometer „2“.

Important: Thermomether must be

Its metal insert must be at the same level as

(By changing the position of the

thermometer will alter the temperature considerably.)

Connect the lambda sensor and exhaust gas thermometer

Loading...

Loading...