SECTION TSM 630 ISSUE J PAGE 5 OF 10

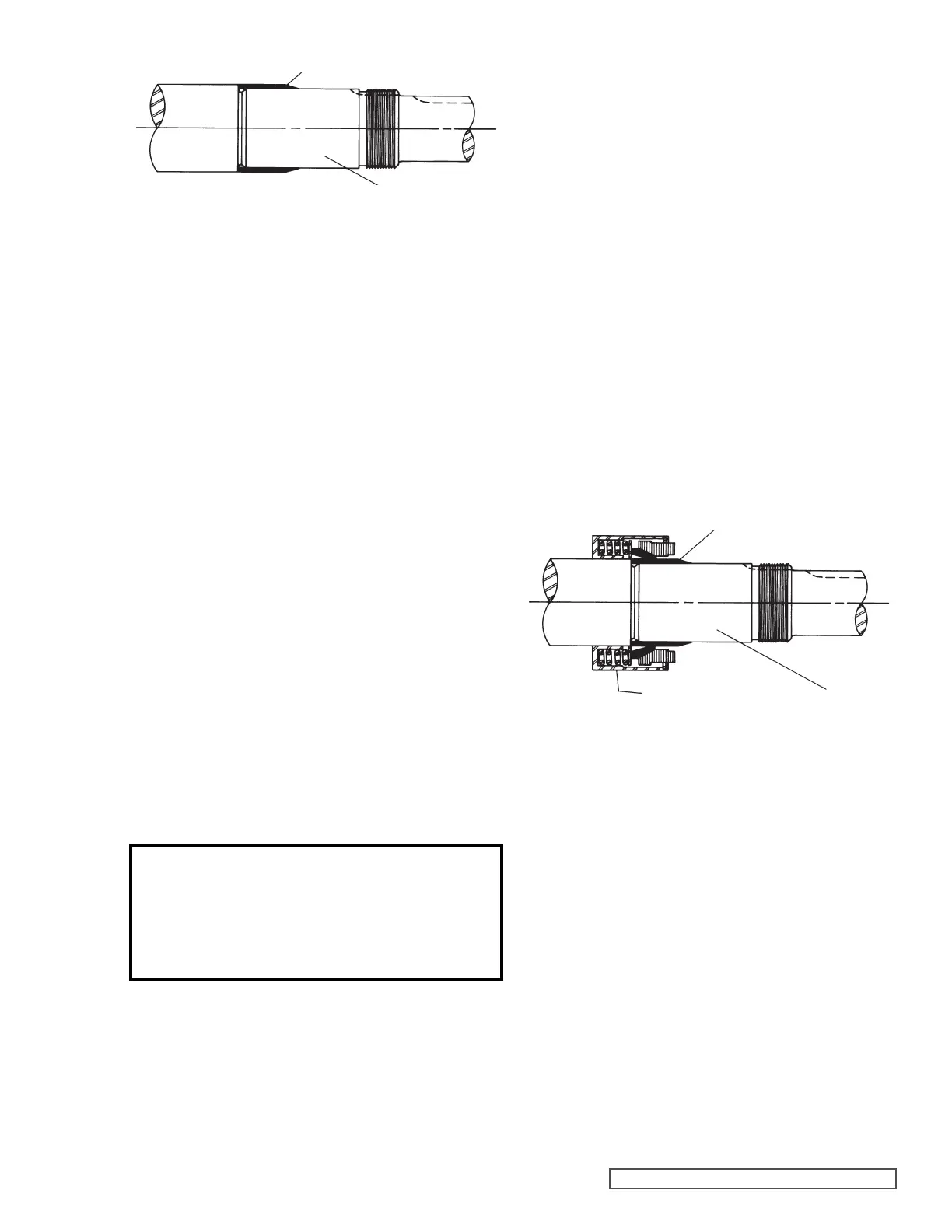

3. Place tapered installation sleeve on shaft. Coat rotor

shaft, tapered installation sleeve, and O-ring in the

inside diameter of cartridge seal sleeve with a generous

amount of light oil. Refer to Figure 7.

4. Slide cartridge seal over installation sleeve on shaft

until it contacts the seal chamber face. Remove tapered

installation sleeve from shaft.

5. Place pair of half round rings in groove on shaft and turn

bearing housing assembly into bracket. There are no

half round rings on the G, H and HL size pumps.

6. Put lockwasher and locknut on shaft. Tighten locknut

and bend one tang of lockwasher into slot of locknut.

Note: G size has no lockwasher.

7. Adjust pump end clearance as in Thrust Bearing

Adjustment page 8.

8. Insert gland capscrews and secure gland to bracket face.

NOTE: turn shaft several turns while gland is loose to

center seal; then tighten gland tight enough to compress

gasket. Tighten only enough to contain leakage and not

to distort gland.

9. Lock cartridge seal drive collar to shaft and remove or turn

centering clips out of the way so as to clear the drive collar.

10. Turn shaft by hand or jog motor to check drive collar for

runout.

11. Connect suckback or flush line or vent stuffing box seals

without flush line until liquid is present on start up.

NOTE: For maximum seal life, suckback or flush line

should be used.

FIGURE 7

TAPERED INSTALLATION SLEEVE

COAT ROTOR SHAFT, TAPERED INSTALLATION

SLEEVE AND INNER DIAMETER OF MECHANICAL

SEAL WITH LIGHT OIL BEFORE ASSEMBLY.

SHAFT

DANGER !

Before starting pump, be sure all drive equipment

guards are in place.

Failure to properly mount guards may result in

serious injury or death.

ASSEMBLY

COMPONENT MECHANICAL SEAL

MODELS:

G, H, HL, AK, AL, K, KK, L, LQ, AND LL4124A CAST IRON

L, LQ AND LL 4124AE CAST IRON

H, HL, K, KK, L, LQ, AND LL4126A DUCTILE IRON

H, HL, K, KK, LQ, AND LL4123A STEEL EXTERNALS

H, HL, K, KK, LQ AND LL4127A STAINLESS STEEL

This seal type can be installed as an alternate to the cartridge

mechanical seal. The seal is setscrew driven, is simple to

install and good performance will result if care is taken during

installation.

For complete pump disassembly and assembly see pages

6 and 7. For Step 6, disassembly, remove the appropriate

nuts, capscrews, seal holder and seal seat. Remove the pipe

plug in the bracket and loosen the setscrews holding the

mechanical seal rotary member to the shaft. This must be

done before the rotor is removed to avoid damage to the seal

and the rotor shaft.

The following steps are for mechanical seal assembly.

1. Clean rotor shaft and seal housing bore. Make sure

they are free of dirt, grit and scratches. Gently radius

leading edge of the shaft diameter over which seal is to

be placed.

Never touch mechanical seal faces with anything except

clean hands or clean cloth. Minute particles can scratch

the seal faces and cause leakage.

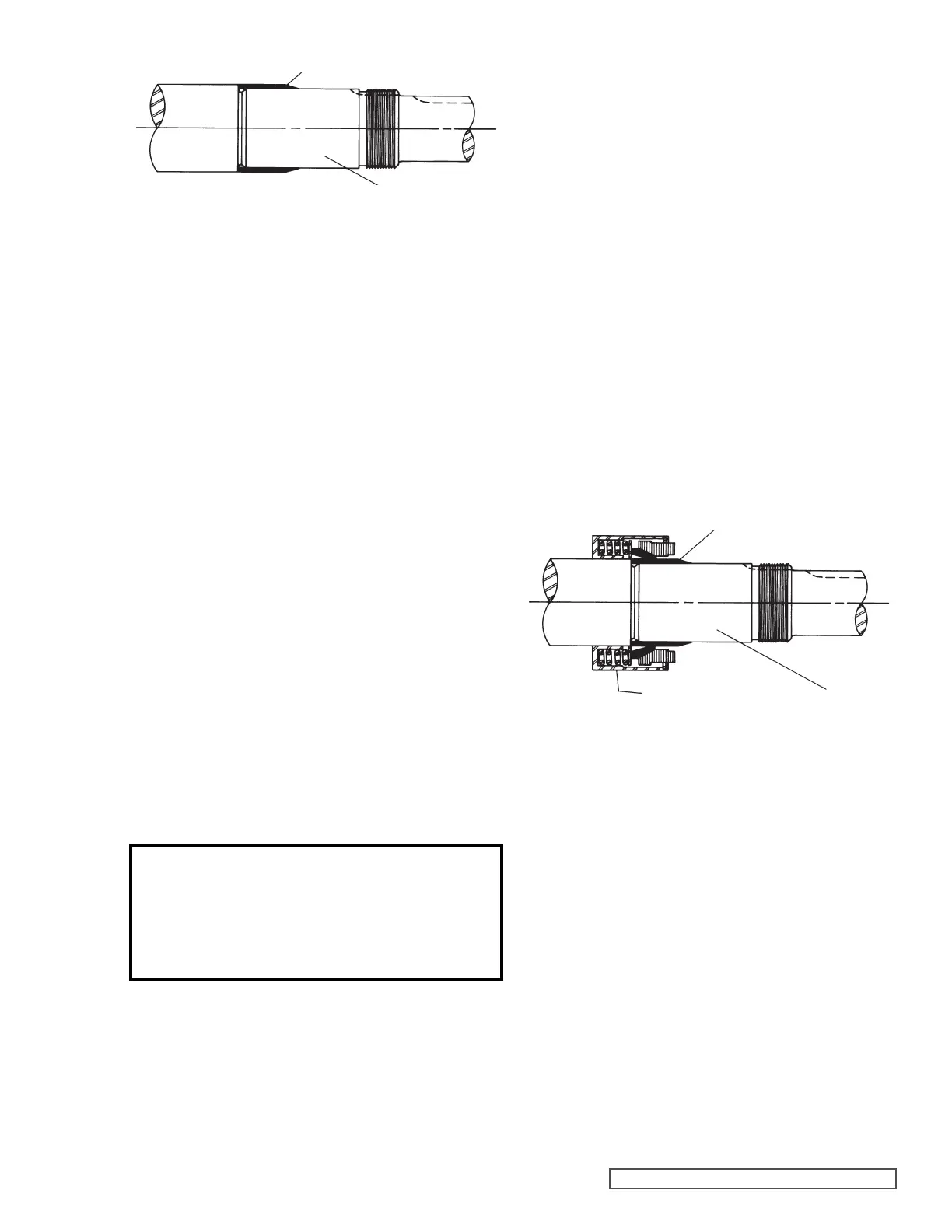

2. Place tapered installation sleeve on the shaft. Coat

tapered sleeve and inside of the rotary member

with a generous quantity of light oil. Grease is not

recommended. Start rotary member on shaft and over

tapered sleeve. Refer to Figure 8.

FIGURE 8

TAPERED INSTALLATION SLEEVE

SHAFT

MECHANICAL SEAL

ROTARY MEMBER

3. Move rotary member so setscrews are directly below seal

access holes on side of bracket. Tighten all setscrews

securely to shaft. Some seals are equipped with holding

clips which compress the seal springs. Remove holding

clips to release springs after seal is installed on shaft.

4. FOR “O-RING” GASKET TYPE MECHANICAL SEAL

SEAT: Lubricate outer diameter of O-Ring seal gasket

with oil. Flush sealing faces of both rotary member and

seal seat with oil and press seal seat in to bore until back,

unlapped face, is flush with bore. Install seal holder,

capscrews, and nuts and tighten securely. Remove

tapered installation sleeve.

FOR “CLAMPED-IN” TYPE MECHANICAL SEAL

SEAT: Flush sealing faces of both rotary member and

seal seat with oil and install seal seat and seat gasket

over end of shaft against machined bracket face. Install

other seal gasket, seal holder, capscrews, and nuts and

tighten securely. Remove tapered installation sleeve.

5. Connect suckback or flush line or vent stuffing box for

seals without flush line until liquid is present on start up.

NOTE: For maximum seal life, suckback or flush line

should be used.

Loading...

Loading...