SECTION TSM 630 ISSUE J PAGE 8 OF 10

When installing carbon graphite bushings, extreme care

must be taken to prevent breaking. Carbon graphite is a

brittle material and easily cracked. If cracked, the bushing will

quickly disintegrate. Using a lubricant and adding a chamfer

on the bushing and the mating part will help in installation.

The additional precautions listed below must be followed for

proper installation.

1. A press must be used for installation.

2. Be certain bushing is started straight.

3. Do not stop pressing operation until bushing is in proper

position. Starting and stopping will result in a cracked

bushing.

4. Check bushing for cracks after installation.

Carbon graphite bushings with extra interference fits are

frequently furnished for high temperature operation. These

bushings must be installed by a shrink fit.

1. Heat bracket or idler to 750ºF.

2. Install cool bushing with a press.

3. If facilities are not available to reach 750ºF. temperature,

it is possible to install with 450ºF. temperature; however

the lower the temperature the greater the possibility of

cracking the bushing.

Consult factory with specific questions on high temperature

applications. Refer to Engineering Service Bulletin ESB-3.

INSTALLATION OF CARBON

GRAPHITE BUSHINGS

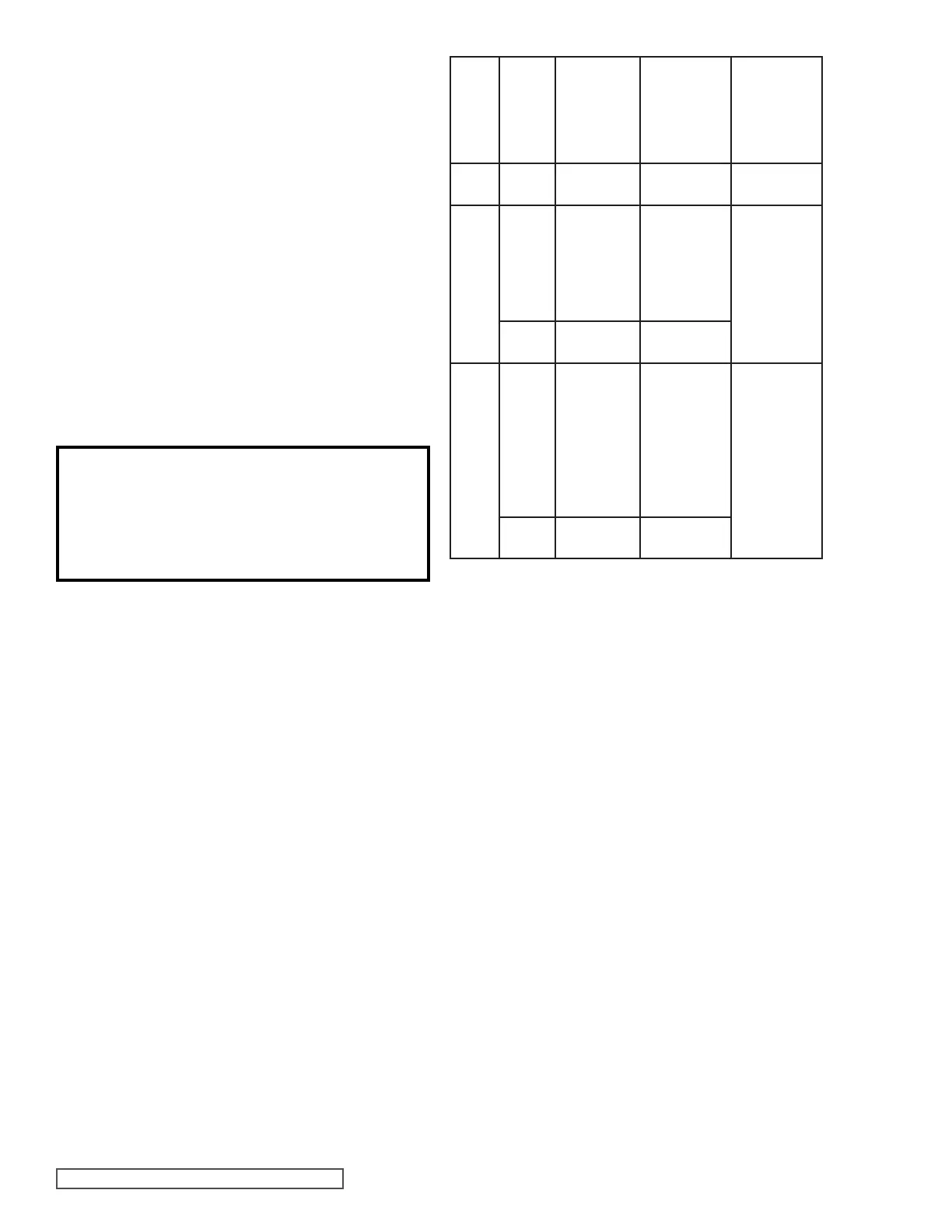

PUMP

SIZE MODEL

STANDARD

END

CLEARANCE

(INCH)

TURN

BEARING

HOUSING

CCW LENGTH

ON OD (INCH)

ADDITIONAL

LENGTH ON

OD BEARING

HOUSE FOR

0.001" END

CLEARANCE

(INCH)

G

124A

4124A

0.003” 0.60” 0.20”

H

HL

124A

4124A

126A

4126A

123A

4123A

0.003” 0.75”

.22”

127A

4127A

0.005” 1.125”

AK

AL

K

KK

L/LQ

LL

124A

4124A

124AE

4124AE

126A

4126A

123A

4123A

0.005” 1.25”

.25”

127A

4127A

0.008” 2”

1. Loosen the two set screws in the outer face of the

bearing housing and turn this thrust bearing assembly

clockwise until it can no longer be turned by hand. Back

off counter-clockwise until the rotor shaft can be turned

by hand with a slight noticeable drag.

2. For standard end clearance, back off the thrust bearing

assembly the required length measured on the outside

diameter of the bearing housing. See Table 2.

3. Tighten the two self-locking type “Allen” set screws, in

the outboard face of the bearing housing, with equal

force against the bracket. Your pump is now set with

standard end clearances and locked.

NOTE: Be sure the shaft can rotate freely. If not, back off

additional length on outside diameter and check again.

4. High viscosity liquids required additional end

clearances. The amount of extra end clearance depends

on the viscosity of the liquid pumped. For specific

recommendations, consult your Viking Pump distributor.

THRUST BEARING ADJUSTMENT

SIZE G, H, HL, AK, AL, K, KK, L, LQ

& LL PUMPS

TABLE 2 - END CLEARANCE CHART

9. Install the lipseal (with lip toward end of shaft) and

bearing spacer collar in the outer end cap and turn the

end cap into the bearing housing until tight against the

bearing. Lock in place with two set screws in the flange

of the bearing housing.

10. Put lockwasher and locknut on shaft. Insert length of

hardwood or brass through port opening between rotor

teeth to keep shaft from turning. Tighten locknut to

20-30 ft.–lbs. torque (G), 50-70 ft.–lbs. torque (H, HL) or

100-130 ft.–lbs. torque (AK, AL, K, KK, L, LQ, LL). Bend

one tang of lockwasher into slot of locknut. If tang does

not line up with slot, tighten locknut until it does. Failure

to tighten locknut or engage lockwasher tang could result

in early bearing failure and cause damage to pump.

Remove length of hardwood or brass from port opening.

11. Adjust pump end clearance as in Thrust Bearing

Adjustment page 8.

12. Lubricate all grease fittings with multi-purpose grease,

NLGI #2. G size has sealed bearing and is not

regreasable.

DANGER !

Before starting pump, be sure all drive equipment

guards are in place.

Failure to properly mount guards may result in

serious injury or death.

Loading...

Loading...