VOLCANO VR Mini

VOLCANO VR1

VOLCANO VR2

VOLCANO VR3

VOLCANO VR-D

VR Mini, VR1, VR2, VR3, VR-D

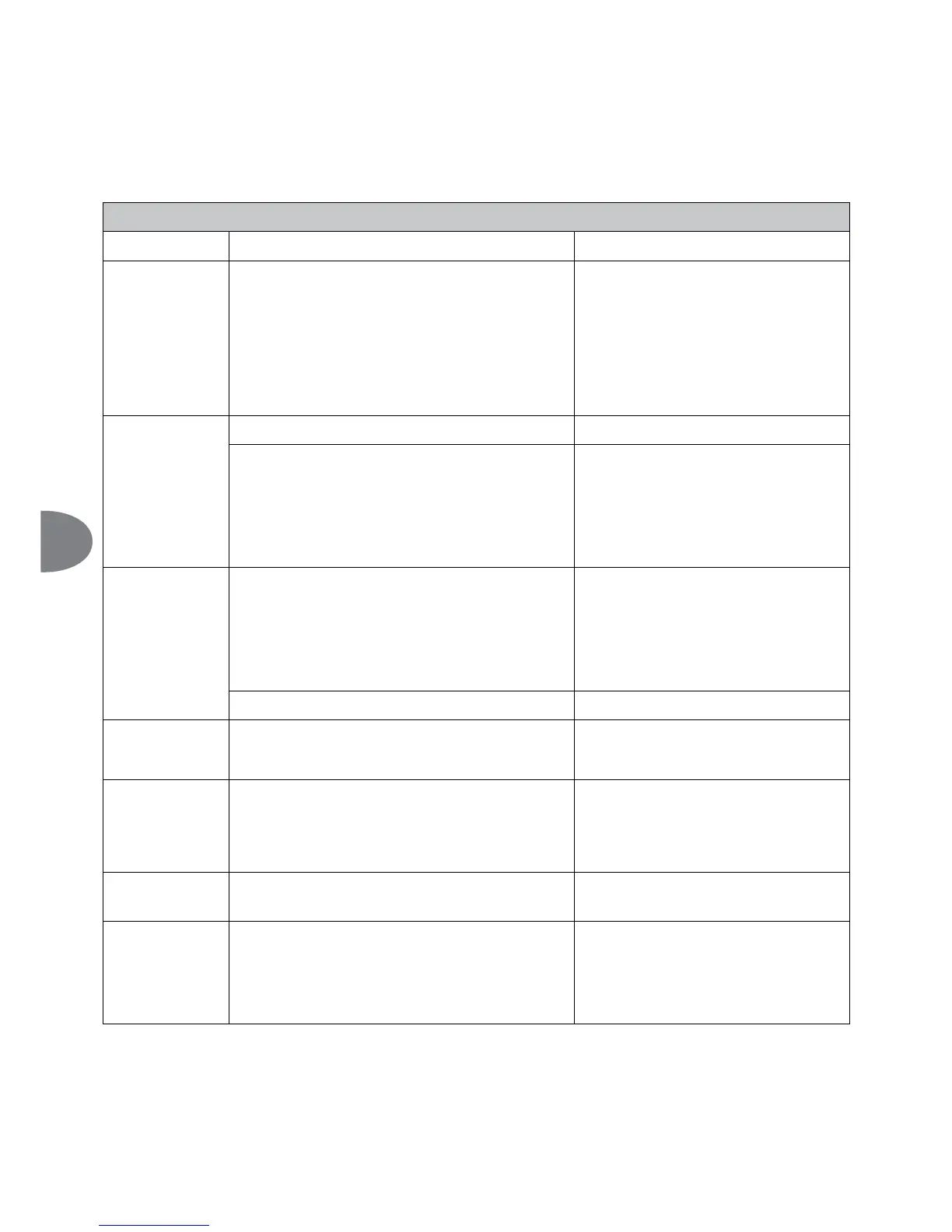

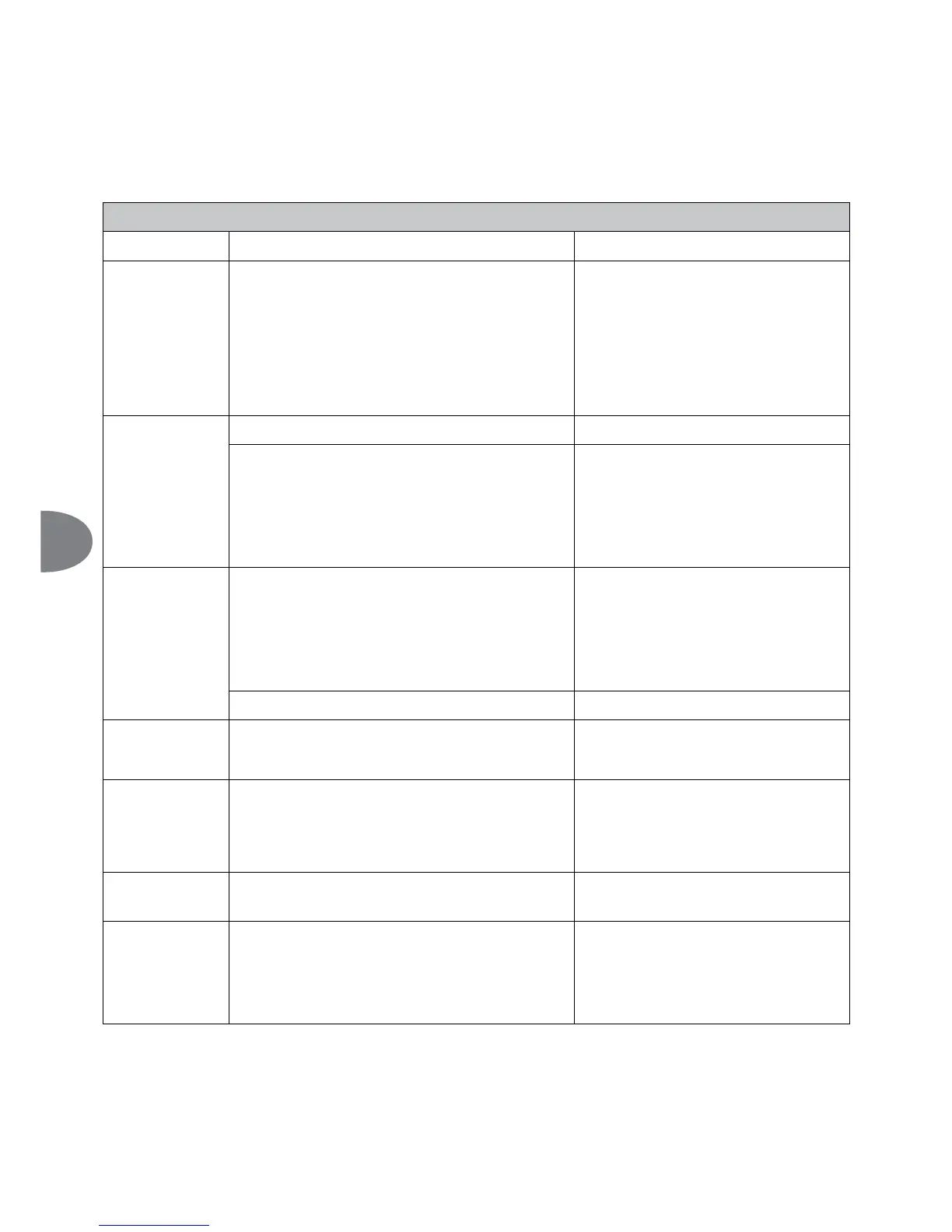

Problem Check points Description

Heat exchanger leaking

Ɣ DVVHPEO\RIWKHH[FKDQJHUFRQQHFWLRQVZLWKWZRZUHQFKHVDGMXVWPHQWZKLFK

safeguards against internal twisting of the collectors,

Ɣ &KHFNLIWKHOHDNDJHPD\EHDVVRFLDWHGZLWKPHFKDQLFDOGDPDJHWRWKH

exchanger,

Ɣ 9HQWYDOYHRUGUDLQSOXJOHDNLQJ

Ɣ +HDWLQJDJHQWSDUDPHWHUVSUHVVXUHDQGWHPSHUDWXUH±VKRXOGQRWH[FHHG

permitted values,

Ɣ W\SHRIKHDWLQJDJHQWLWFDQQRWEHDJJUHVVLYHWR$ODQG&X

Ɣ &LUFXPVWDQFHVZKHQWKHOHDNDJHDSSHDUVHJGXULQJWKH¿UVWWHQWDWLYH

LQVWDOODWLRQVWDUWXSZKHQWKHLQVWDOODWLRQLV¿OOHGXSDIWHUWKHKHDWLQJDJHQW

has been drained) and outside temperature at the time of failure (risk that the

exchanger may freeze),

Ɣ 3RVVLELOLW\RIRSHUDWLQJLQDJJUHVVLYHFRQGLWLRQVHJKLJKFRQFHQWUDWLRQRI

ammonia in the air in a sewage-treatment plant),

Pay special attention that the exchanger may freeze during winter

WLPHRIUHJLVWHUHGOHDNDJHVDSSHDUGXULQJLQVWDOODWLRQVWDUWXS

pressure tests. The defect can be removed by pulling back vent or

drain valve.

)DQZRUNVWRRORXG

Ɣ FKHFNWKHGHYLFHDVVHPEO\IRUFRQIRUPLW\ZLWKWKHLQVWUXFWLRQVLQRSHUDWLRQDQG

maintenance manual (e.g. distance from wall/ceiling),

min. 40 cm

Ɣ 'HYLFHDSSURSULDWHO\OHYHOOHG

Ɣ &RUUHFWQHVVRIHOHFWULFFRQQHFWLRQVDQGTXDOL¿FDWLRQVRIWKHZLUHPDQ

Ɣ ,QOHWFXUUHQWSDUDPHWHUVHJYROWDJHIUHTXHQF\

Ɣ XVHRIURWDWLRQFRQWUROOHUGLIIHUHQWIURP$5:

Ɣ QRLVHDWORZHUJHDUVSRVVLEOHFRQWUROOHUIDLOXUH"

Ɣ 1RLVHRQO\DWKLJKHUJHDUVUHJXODUVLWXDWLRQH[SODLQHGE\DHURG\QDPLF

characteristics of the device, if there outlet air chokes),

Ɣ W\SHRIRWKHUGHYLFHVRSHUDWLQJLQWKHEXLOGLQJHJLQGXFHGGUDXJKWIDQV±

LQWHQVL¿HGQRLVHFDXVHGE\VLPXOWDQHRXVRSHUDWLRQRIPDQ\PDFKLQHV

Ɣ 'RHVWKHIDQUXEDJDLQVWWKHFDVLQJ"

Ɣ ,VWKHIDQHYHQO\VFUHZHGWRWKHFDVLQJ"

Level of operating noise of VOLCANO devices is perceived

subjectively. If the device is made of plastic, it should operate

quietly.It is recommended to unscrew the clamping screws and

tightening them up again. If the fault does not disappear, you should

make a complaint.

)DQGRHVQRWZRUN

Ɣ &RUUHFWQHVVDQGTXDOLW\RIHOHFWULFFRQQHFWLRQVDQGTXDOL¿FDWLRQVRIWKHZLUHPDQ

Ɣ ,VWKHUHDQDGGLWLRQDOEULGJHEHWZHHQUHTXLUHGHQJLQHWHUPLQDOVGLDJUDPLQWKH

manual) – U1 – TK (TB),

Ɣ ,QOHWFXUUHQWSDUDPHWHUVHJYROWDJHIUHTXHQF\RQWKHFODPSEORFNRIIDQ

engine,

Ɣ &RUUHFWQHVVRIRSHUDWLRQRIRWKHUGHYLFHVLQVWDOOHGLQWKHEXLOGLQJ

Ɣ &RUUHFWQHVVRIZLUHFRQQHFWLRQVRQWKHHQJLQHVLGHDFFWRWKHPDQXDOLQ

comparison to wires clamped in the engine terminal strip,

Ɣ 3(FRQGXFWRUYROWDJHLISUHVHQWPD\PHDQWKHUHLVDEUHDNGRZQ

Ɣ ,V1FRQGXFWRUFRUUHFWO\FRQQHFWHGWRWKHIDQRU$5:RULVWKHFRQQHFWLRQRI8

FODPSVRQWKHPRWRUDQG$5:PDGHFRUUHFWO\"

(OHFWULFDOFRQQHFWLRQQHHGWREHGRQHVWULFWO\DFFRUGLQJWRWKH

drawings in the manual. If there is no bridge between U1 and

TK(TB) clamps, the motor lacks thermal protection and may break

– burn.

Ɣ GDPDJHRULQVWDOODWLRQRIFRQWUROOHUGLIIHUHQWIURP$5:

It is recommended to check the device/ speed controller by

connecting the heater directly to power supply.

Damaged casing

Ɣ &LUFXPVWDQFHVZKHQLWZDVGDPDJHG±QRWHVRQWKHELOORIODGLQJ

VVWRFNLVVXH

FRQ¿UPDWLRQFRQGLWLRQRIWKHER[

If the casing is damaged, make photos of the box and device, and

SKRWRVFRQ¿UPLQJWKDWWKHGHYLFHVHULDOQXPEHURQWKHGHYLFH

and on the box are the same. If the device was damaged during

transport, it is necessary to write down an appropriate statement by

the driver, who delivered the damaged device.

ARW – rotation controller

GRHVQRWZRUNLWLVEXUQHG

Ɣ &RUUHFWQHVV±TXDOLW\RIHOHFWULFFRQQHFWLRQVZLUHVDFFXUDWHO\SRVLWLRQHG

in electric clamps, cross-section and the material wires are made of) and

TXDOL¿FDWLRQVRIWKHZLUHPDQ

Ɣ 2QO\FRQWUROOHUFRQQHFWHGWRGHYLFH

Ɣ ,QOHWFXUUHQWSDUDPHWHUVHJYROWDJHIUHTXHQF\

Ɣ &RUUHFWQHVVRI92/&$12RSHUDWLRQDIWHUFRQQHFWLQJ³LQVKRUW´VNLSSLQJ$5:LH

FRQQHFWLRQV/DQG7%1DQG83(DQG3(WRWKHSRZHUQHWZRUN

Ɣ &KHFNLIWKHXVHUGLGQRWGDPDJHWKHNQREHJURWDWLQJLWDURXQG

)RUWKH75$165$7(FRQWUROOHUWKHIROORZLQJPXVWDOVREH

checked:

Ɣ FLUFXLWEUHDNHU

Ɣ FRUUHFWQHVVRIFRQQHFWLRQWRWKH6&5FRQWUROOHU

Ɣ XVHRIVKLHOGHGFRQGXFWRUV

Ɣ FRQWUROFRQGXFWRUVZKLFKVKRXOGEHORFDWHGDZD\IURPWKH

working conductors

Actuator does not open

the valve

Ɣ &RUUHFWQHVVRIHOHFWULFFRQQHFWLRQVDQGTXDOL¿FDWLRQVRIWKHZLUHPDQ

Ɣ &RUUHFWQHVVRIWKHWKHUPRVWDWRSHUDWLRQFKDUDFWHULVWLFWLFNVRXQGGXULQJFKDQJH

over),

Ɣ ,QOHWFXUUHQWSDUDPHWHUVHJYROWDJH

The most important is to check whether the actuator responded

to the electric impulse within 11s. If the motor is damaged, you

need to make a complain and switch actuator operation to manual

(MAN), which mechanically opens the valve.

Programmable thermostat

does not send any signals

to the actuator/ controls

the operation of the

KHDWLQJV\VWHPZURQJO\

Ɣ &RUUHFWQHVVRIHOHFWULFFRQQHFWLRQVDQGTXDOL¿FDWLRQVRIWKHZLUHPDQ

Ɣ &RUUHFWQHVVRIWKHWKHUPRVWDWRSHUDWLRQFKDUDFWHULVWLFWLFNVRXQGGXULQJVZLWFK

over),

Ɣ &RQQHFWLQJDIHZPRWRURI92/&$12GHYLFHVGLUHFWO\WRWKHWKHUPRVWDW

(permitted only if contactor is used!),

Ɣ ,QOHWFXUUHQWSDUDPHWHUVHJYROWDJH

Ɣ 3URJUDPPLQJPHWKRGH[DFWO\WKHVDPHDVLQWKHPDQXDORQ

www.vtsgroup.com,

Ɣ :KHQZDVWKHODVWWLPHWKHVHQVRUZDVFDOLEUDWHG"

5'(WKHUPRVWDWLVSRZHUHGE\EDWWHULHVWKDWQHHGWREHUHSODFHG

(every 2 years). Also, the sensor needs to be periodically calibrated

– detailed information can be found on: www.vtsgroup.com

&RPSODLQWLVXQMXVWL¿HGLIWKH5'(WKHUPRVWDWZDVGLUHFWO\

connected to the motor, without a contactor. If the sensor incorrectly

measures the temperature, it should be calibrated (instructions in

the catalogue).

9. SERVICING

9.1 PROCEDURES IN CASE OF DEFECTS

40

EN

Loading...

Loading...