Do you have a question about the Volvo Penta D16 MH MCC and is the answer not in the manual?

Covers engine handling, checks, maneuvering, fuel, starting, and accident prevention.

Discusses carbon monoxide, safety equipment, and general reminders for hazard awareness.

Details preparation, pre-start checks, and fire/explosion prevention.

Specific safety advice for hot parts, chemicals, cooling, fuel, electrical, and batteries.

Information about the limited warranty for Volvo Penta marine engines.

Procedures and recommendations for the engine's initial run-in period and service.

Recommendations for fuel, oil, and coolant to ensure engine performance and longevity.

Volvo Penta's environmental commitment and requirements for certified engines.

Overview of the MCC system, its components, and function.

Detailed explanation of the MCU panel buttons, display, and indicators.

Explanation of the display elements, engine status, and modes.

Description of the system's main menu and measurement menu navigation.

How to navigate and change setpoints in the adjustment menu.

How to browse and view event history and detailed information.

Procedures for checking serial numbers, adjusting backlighting, changing language, and setting passwords.

Explanation of Local mode, Operations mode (PRP), and Off mode.

How to access and view operational statistics.

How the alarm system functions and how to view the alarm list.

Overview of the SDU's channels, emergency mode, run detection, and broken wire features.

Explanation of the SDU's LED indicators and control panel functions.

Critical checks and safety procedures to follow before starting the engine.

Details on engine control lever, pre-heating, and idling speed.

Step-by-step guide to starting the engine in PRP mode.

How to monitor running data not shown in the main menu.

How alarms are shown, acknowledged, and cleared.

Instructions on safe shifting between ahead and astern at idle revolutions.

Procedures for stopping the engine normally.

How to use the emergency stop button and reset it.

Checks and actions to perform after the engine has been shut down.

Recommendations for warming up the engine during operational breaks.

Measures to prevent damage from freezing temperatures.

How malfunctions are communicated and how the system protects the engine.

How to acknowledge and clear alarms from the list.

How to access and interpret the alarm and ECU alarm lists.

Information on fault codes from the engine control or power management systems.

Abbreviations and meanings for alarm list entries.

Table of engine symptoms and their potential causes and corresponding page references.

Continuation of symptoms and possible causes for engine malfunctions.

Covers battery, coolant, oil, and EMS supply issues affecting engine operation.

Details critical faults for temperature, pressure, and overspeed that cause shutdown.

Explains faults related to fuel pressure, battery status, and critical shutdowns.

Covers SDU system failures, overspeed, water in fuel, and performance derating.

Details SDU system failures, underspeed conditions, and 30V supply faults.

Procedure for manually shifting the reverse gear in an emergency.

Safety precautions and steps for jump-starting a dead battery.

Special warranty inspection requirements during initial engine use.

Conditions for extending engine oil change intervals.

Overview of service types and intervals for inspections, adjustments, and replacements.

Details maintenance tasks for 1000, 2000, 3000, and 8000 hours/intervals.

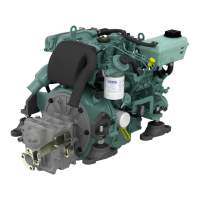

Labels and identifies key components of the D16C MH-TD MG5170 engine.

Routine visual checks of the engine and engine bay for abnormalities.

Procedure for checking and replacing the engine air filter.

Instructions for checking and replacing drive belts for water pump and alternator.

Procedure for changing engine oil and by-pass filters.

Instructions for checking and topping up engine oil level.

Procedures for changing engine oil and oil filters.

Procedure for changing engine oil and by-pass filters.

Procedure for changing switchable oil filters.

General guidelines for fuel system maintenance and safety.

Step-by-step guide for replacing engine fuel filters.

Procedures for checking and draining the fuel pre-filter.

Procedure for replacing double fuel filter cartridges.

Steps for venting the fuel system after filter changes or long stoppages.

Checking and draining the fuel pre-filter.

Procedure for replacing double fuel filter cartridges.

Diagram and explanation of the engine-mounted heat exchanger cooling system.

Identification of raw water and fresh water drain points on engine models.

Diagram and explanation of cooling systems without an engine-mounted heat exchanger.

Details of the engine's internal freshwater cooling system and coolant requirements.

Instructions on mixing coolant concentrate with water for proper protection.

Procedures for checking and topping up the coolant level.

Steps for draining coolant from the system.

Procedure for flushing the freshwater cooling system.

Procedures for checking and replacing zinc anodes in the heat exchanger.

Steps for checking and replacing the seawater pump impeller.

Procedure for checking and cleaning the seawater filter.

Checking the drain hole at the bottom of the charge air cooler.

Explanation of the power module's function in supplying EMS and MCC systems.

Important precautions regarding the use of main switches.

Checks for electrical connections to ensure dryness, freedom from oxide, and secure tightening.

Safety precautions and steps for maintaining engine batteries.

Safety guidelines and procedures for charging engine batteries.

Advice on electrical installation design and safety practices.

Step-by-step guide for connecting and disconnecting the battery.

Safety precautions and procedures when performing electrical welding on the engine.

Procedures for checking and topping up reverse gear transmission lubricant.

Steps for changing the reverse gear oil.

Procedure for changing the engine oil filter.

Procedure for cleaning the oil strainer in the reverse gear.

Lubrication of the output shaft bearing seal on Twin Disc reverse gear.

General guidelines and checklist for preparing the engine for long-term storage.

Specific steps for preparing the engine for storage up to eight months.

Procedures for conserving lubricating and fuel systems for stops longer than eight months.

Steps for preparing the engine after a storage period and bringing it back into operation.

Table of technical data for different engine models, including rating, torque, and weight.

Details on oil capacity, grade, and change intervals, and viscosity.

Fuel specifications, sulfur content, and density requirements.

Freshwater system capacity and coolant types.

System voltage, alternator specifications, and battery electrolyte density.

Technical data for Twin Disc reverse gears, including ratios and weight.

Information on engine and transmission type plates for ordering parts.

| Engine Model | D16 MH MCC |

|---|---|

| Engine Type | Diesel |

| Cylinder Configuration | Inline |

| Number of Cylinders | 6 |

| Displacement | 16.1 liters |

| Bore | 144 mm |

| Stroke | 165 mm |

| Compression Ratio | 17.5:1 |

| Aspiration | Turbocharged and aftercooled |

| Fuel System | Common Rail |

| Lubrication System | Wet sump |

| Maximum Power Output | 551 kW (750 hp) |

| Emission Standards | IMO Tier II |

| Cooling System | Heat exchanger |