II

.-

-

-

•

--

. -

.......

,

...

,.

li~

I

·(O'O~rl05

mm)

'

331'5

Group

21

Reconditioning engine

Cylinder head, cfeaning - inspection

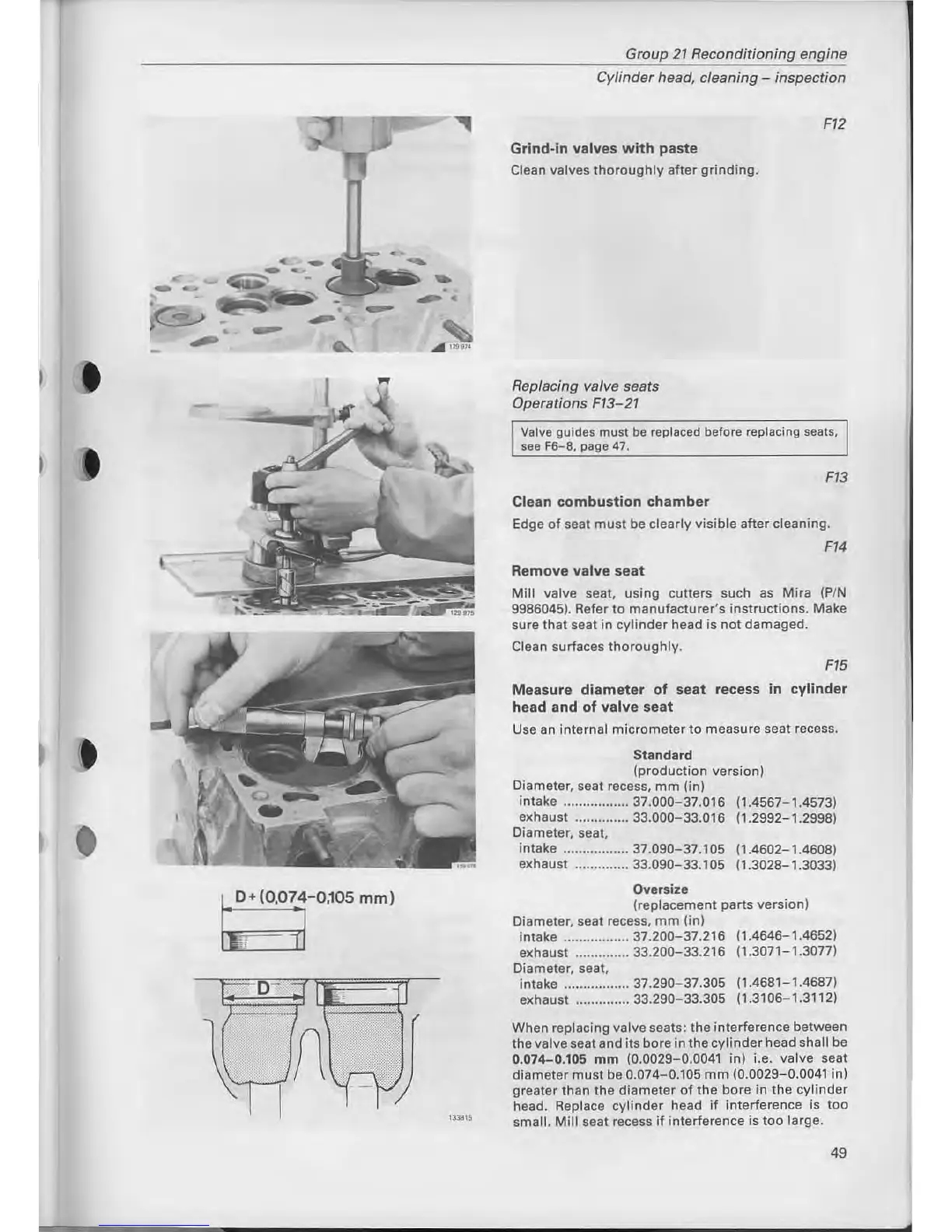

Grind-in valves

with

paste

Clean valves

thoroughly

after

grinding

.

Replacing vafve seats

Operations F13-21

F12

Valve

guides

must

be replaced

before

replacing

seats,

see

F6-8.

page

47.

F13

Clean

combustion

chamber

Edge

of

seat must be clearly visible af

ter

cleaning.

F14

Remove valve

seat

Mill valve seat, using cutters such

as

Mira

(pIN

9986045). Refer to manufacturer's instructions. Make

sure that seat in

cylinder

head is

not

damaged.

Clean surfaces thoroughly.

F15

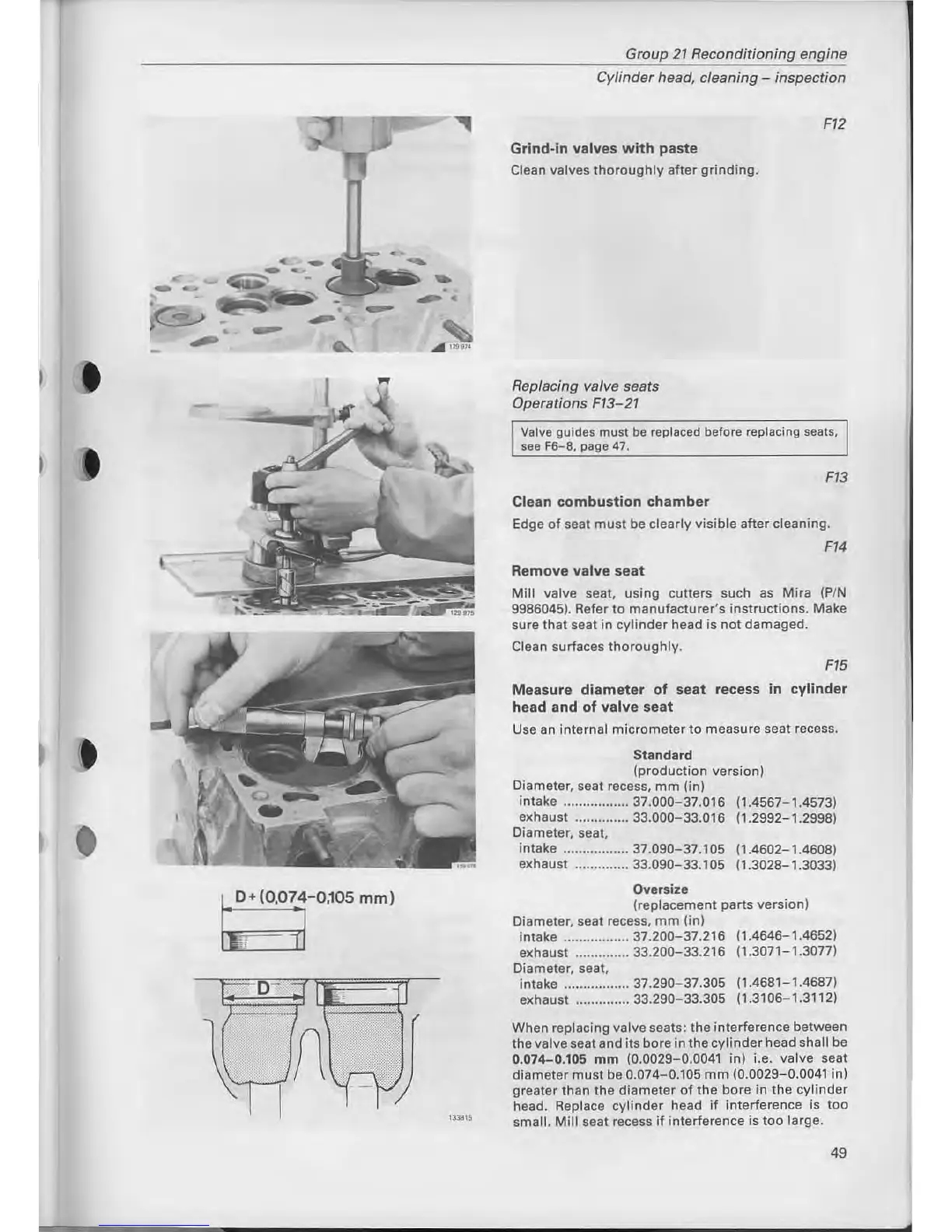

Measure

diameter

of

seat

recess

in cylinder

head

and

of valve

5eat

Use

an

internai

micrometer

to measure seat recess.

Standard

(production version)

Diameter, seat recess,

mm

(in)

intake

.................

37.000-37.016

(1.4567-1.4573)

exhaust ..............

33.000-33.016

(1.2992-1.299B)

Diameter, seat,

intake .................

37.090-37.105

(1.4602-1.460B)

exhaust ..............

33.090-33.105

fl.3028-1.3033)

Oversize

(replacement parts version)

Diameter, seat recess,

mm

(in)

intake .................

37.200-37.216

(1.4646-1.4652)

exhaust ..............

33.200-33.216

(

1.3071-1.3

077)

Diameter, seat.

intake .................

37.290-37.305

11.4681-1.46B7)

exhaust ..............

33.290-33.305

(

1.3106-1.3112)

When replacing valve seats: the interference between

the

valve seat and its bore in the cylinder head shall be

0.074-0.105

mm

(0.0029-0.0041 in) i.e. valve seat

diameter must be

0.074-0.105

mm

(0.0029-0.0041 in)

greater than the

diameter

of

the bore in the cylinder

head. Replace

cylinder head

if

interference

is

too

smal

l.

Mill

seat recess

if

interference is

too

large.

49

Loading...

Loading...