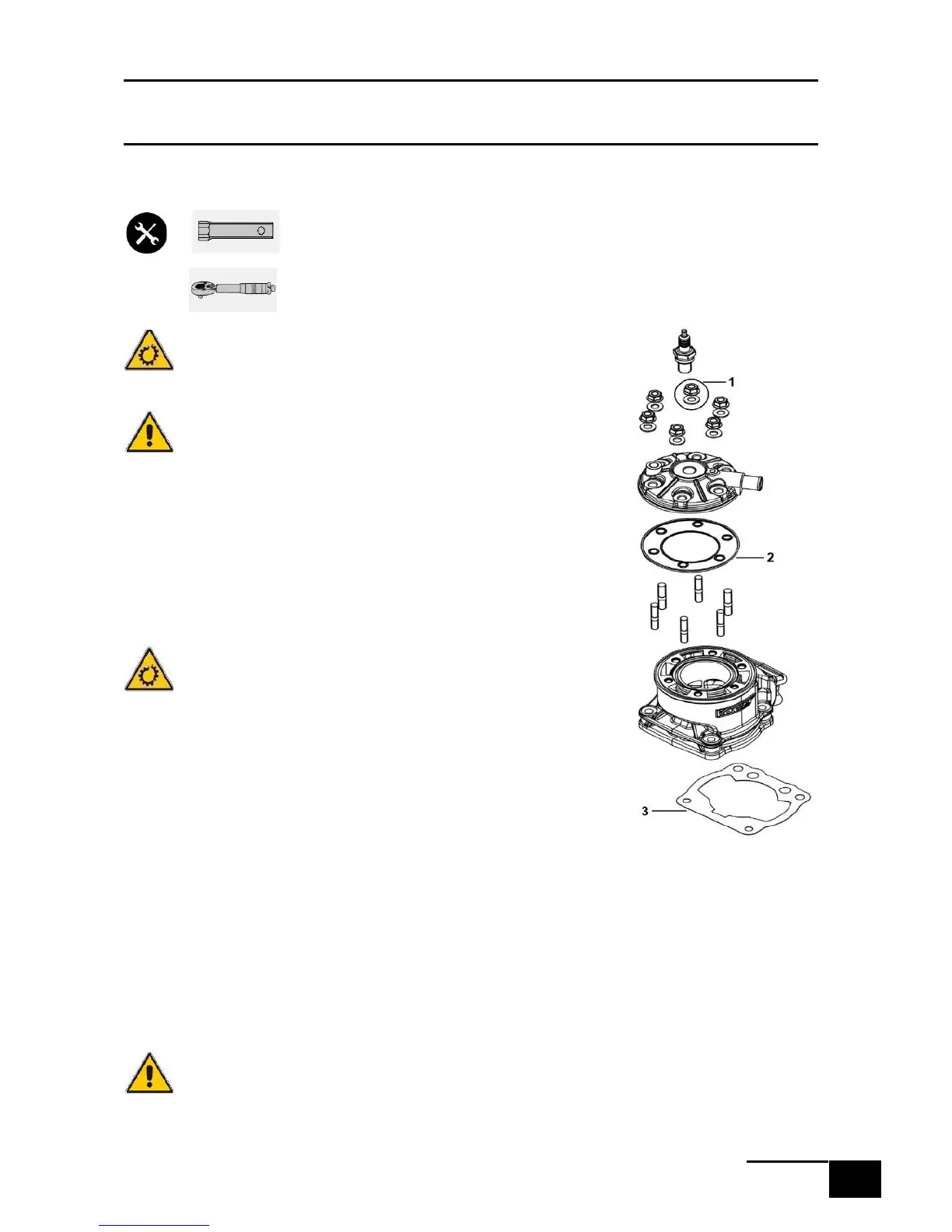

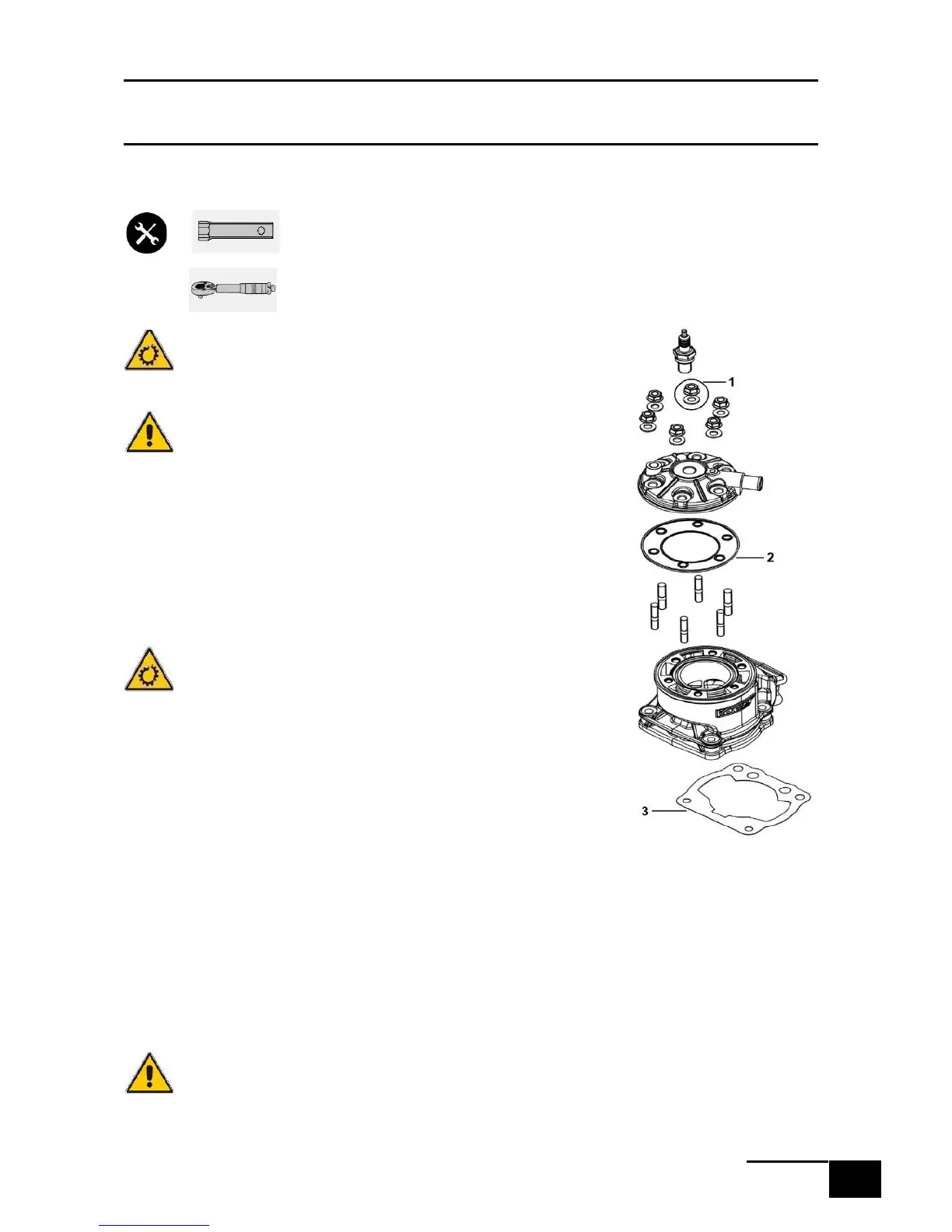

4.6.6 CYLINDER CHECK AND MAINTENEANCE

10mm Tube Wrench

Torque Wrench

To avoid engine damage, a Vortex qualified mechanic

must perform inspection and honing.

Remove exhaust.

Remove spark plug. Remove the six head nuts and

relative washers.

Remove cylinder head by pulling it up carefully.

Remove the cylinder from the crankcase slowly. Once cylinder

is separate from crankcase, hold the connecting rod with the

other hand and pull the cylinder out totally by pulling it up

carefully.

Every time cylinder is removed we recommend changing

cylinder gasket.

Cylinder must be honed when cylinder/piston

clearance is more than 0.12mm or when ovalization is

more than 0.02 mm.

Change piston (see 4.6.7)

New piston cylinder/piston clearance must be 0.12mm.

REASEMBLING

Insert a new gasket on to the studs carefully and place it on the

crankcase surface flat.

Insert now the cylinder in the studs very carefully. With the

other hand close piston ring and inset the piston into the

cylinder. If piston ring is not closed totally, risk of damaging the cylinder and piston ring is very

high. Push the cylinder down firmly. Tight four cylinder nuts with torque wrench at 20Nm.

Insert cooper washer.

Install, carefully, the head onto the studs and check all o-rings are fitted in the right place. If any is

damaged, change it.

Install washers and nuts onto the studs and tight them manually. Now, by using a torque wrench

tighten them alternatively at 1,6 kgm.

Every time cylinder is honed or piston changed, the engine break-in procedure must be

performed.

Loading...

Loading...