5-12 BA 901/1101 en – Edition 2.1 * 91101b520.fm

Maintenance

5.6 V-belts

Only check or retighten/replace the V-belts when the engine is stopped –

Injury hazard!

☞ Stop the engine before performing inspection work in the engine compartment!

☞ Disconnect the battery or the battery master switch!

☞ Let the engine cool down!

Cracked and stretched V-belts cause engine damage

☞ Have the V-belts replaced by an authorized service center!

Check the V-belts once a day or every 10 operating hours, and retighten if necessary.

Retighten new V-belts after about 15 minutes of running time.

Checking V-belt tension

• Check as follows:

☞ Stop the engine

☞ Raise the safety bar

☞ Remove the key and carry it with you

☞ Disconnect the battery or the battery master switch

☞ Let the engine cool down

☞ Open the engine cover

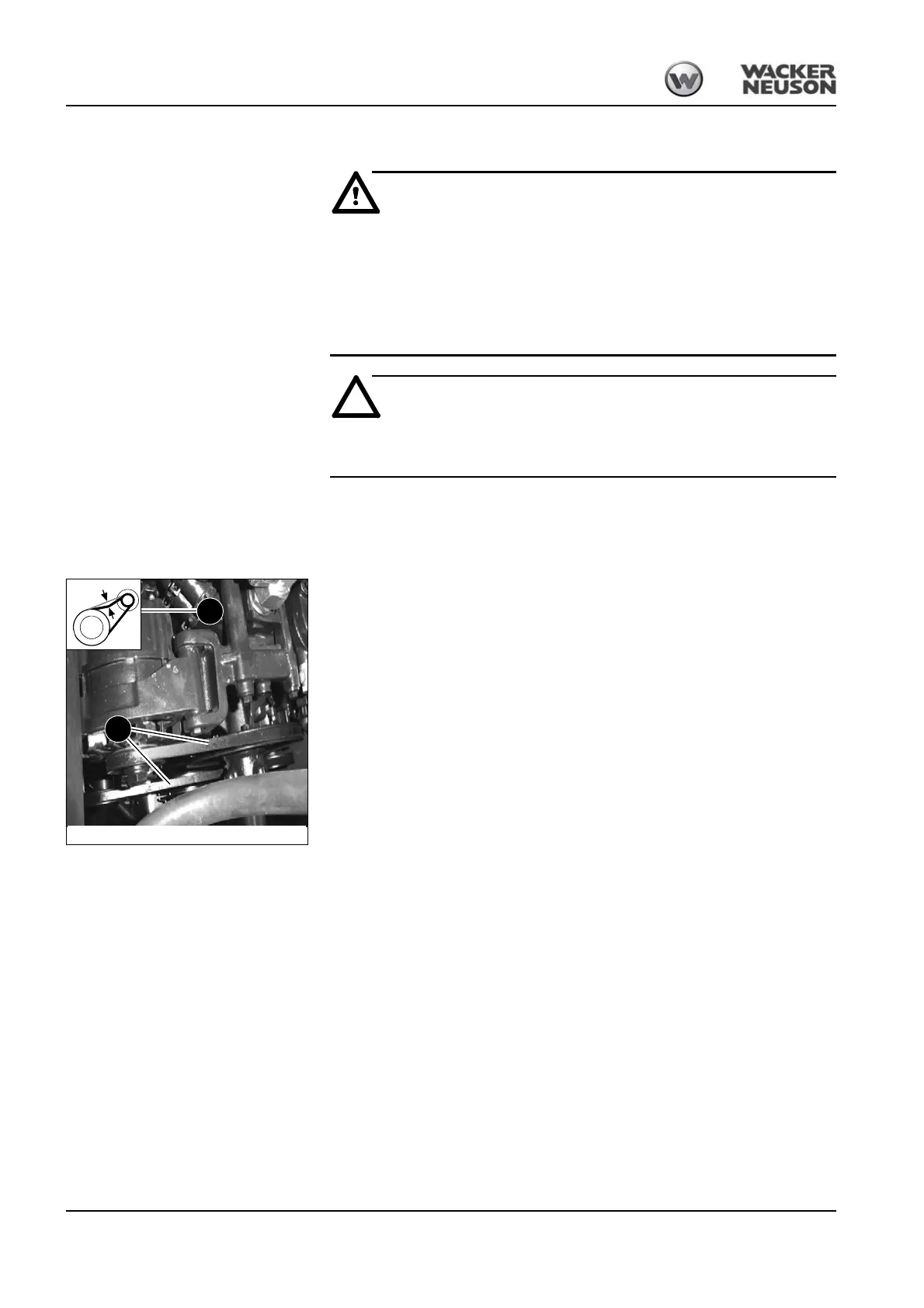

☞ Carefully check V-belts 1 for damage, cracks or cuts

☞ Replace the V-belt if it touches the base of the V-belt groove or the discs of the pulley

• If the V-belt is damaged:

☞ Have the V-belt replaced by authorized personnel

☞ Press with your thumb about 100 N to check the deflection of the V-belt between the

crankshaft disc and the fan wheel. A new V-belt should have a deflection of 6 to 8

mm, a used V-belt (after about 5 minutes running time) should have a deflection of 7

to 9 mm (see 2).

☞ Retighten the V-belt if necessary

Fig. 97: Checking V-belt tension

About 8 mm

2

1

Loading...

Loading...