OM 25-3503 us – Edition 4.1 * * 2503_3503b540.fm 5-39

Maintenance

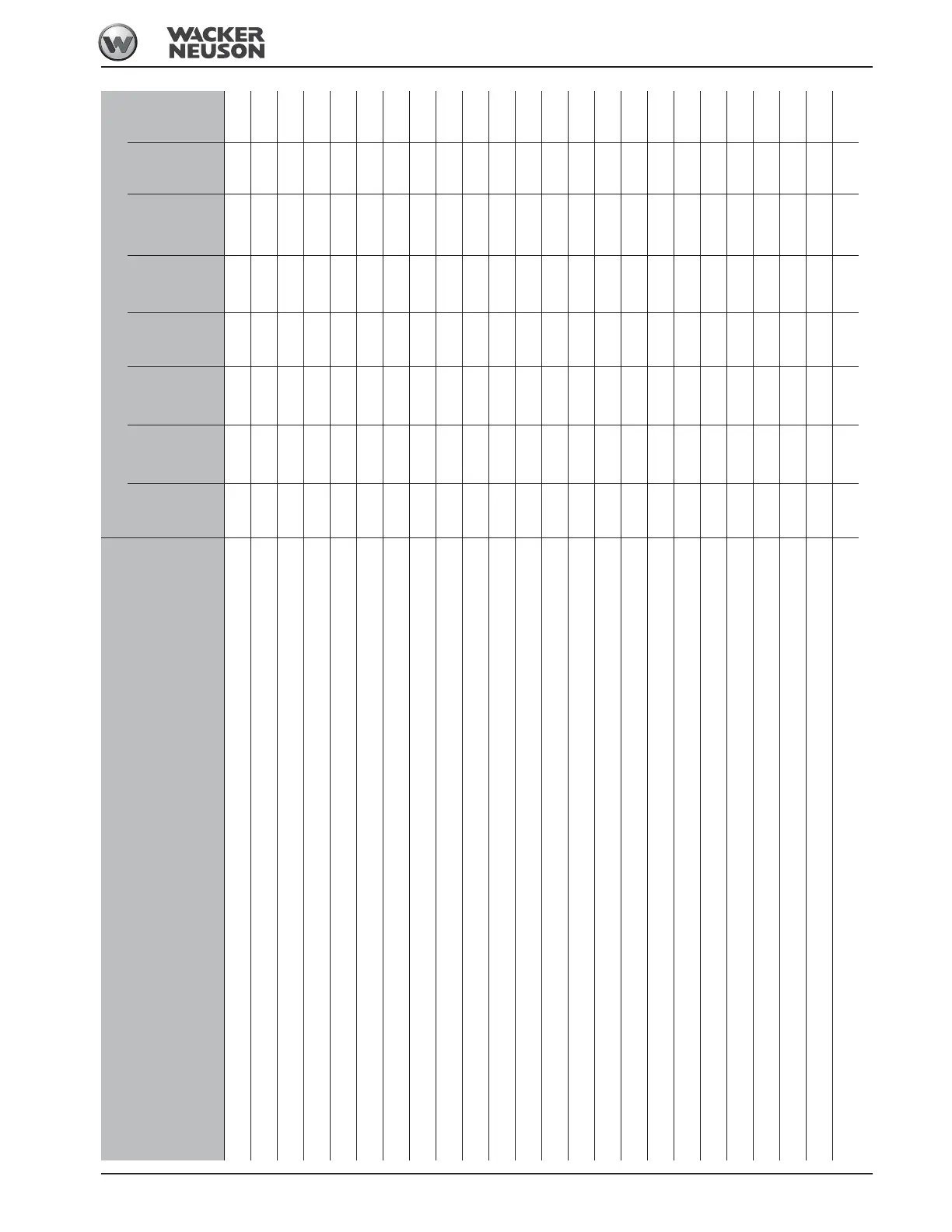

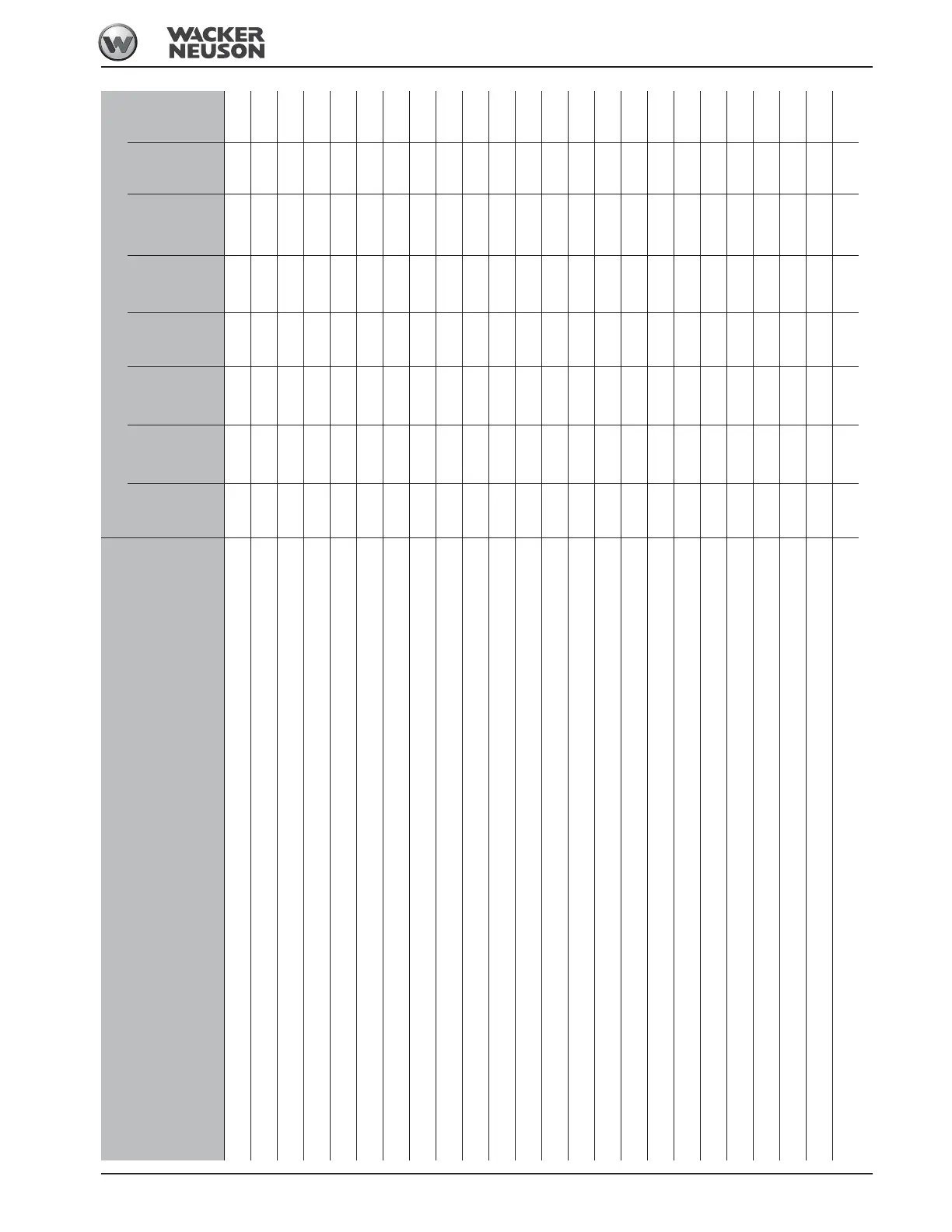

Drain condensation water from the hydraulic oil reservoir (from serial no. AH02272)

●●

Fuel filter: from AG00580: drain 10 ml (0.3 US fl.oz) of fuel/water mixture

●●

Check V-belt condition and tension

●●

Replace the V-belt

●●

Check the exhaust system for damage and condition

●●

Check valve clearance. Adjust if necessary

●●

Clean and adjust the fuel injection pump

8

●●

Check and adjust the injection pressure of the injection nozzles, clean the injection needles/nozzles

●●

Check and adjust injection time

9

●●

Empty diesel fuel tank ●

●

Check battery electrolyte. Add distilled water if necessary

●● ●

Check alternator, starter and electric connections, bearing play and function

●●

Check preheating system and electric connections

●●

Check correct function of air filter contamination gage

●●

Pressure check of primary pressure limiting valves

●● ●

Check tracks for cracks and cuts

●●

Check the track tension and retension the tracks if necessary

●●

Check bearing play of tread rollers, track carrier rollers, front idlers

●●

Check piston rods for damage

●●

Check screws for tightness

●● ●

Check live-ring screws for tightness

●●

Check pin lock

●●

Check wear on load hook and joint rod (lifting eye)

●●

Check line fixtures

●●

5.17 Maintenance plan (overview)

Work description

For servicing and maintenance on the attachment, please refer to the operation and maintenance manual of

the attachment manufacturer as well.

Maintenance plan/operating hours (o/h)

Maintenance

(once a day)

Service

50 o/h

Every 250 o/h

Every 500 o/h

Every 1000 o/h

once a year

Every 2000 o/h

Customer

Authorized

service center

Loading...

Loading...